PVML USER INSTRUCTIONS ENGLISH 00079591 – 01/05

®

environment, these should be removed and disposed

of in accordance with current regulations. This also

includes the liquids and or gases that may be used in

the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3 PUMP DESCRIPTION

3.1 Configuration

The PVML type pump is a heavy duty, single stage,

vertical closed coupled type centrifugal pump,

designed for petrochemical complexes, chemical

plants, general service and circulating applications. It

can only be used with an electric motor.

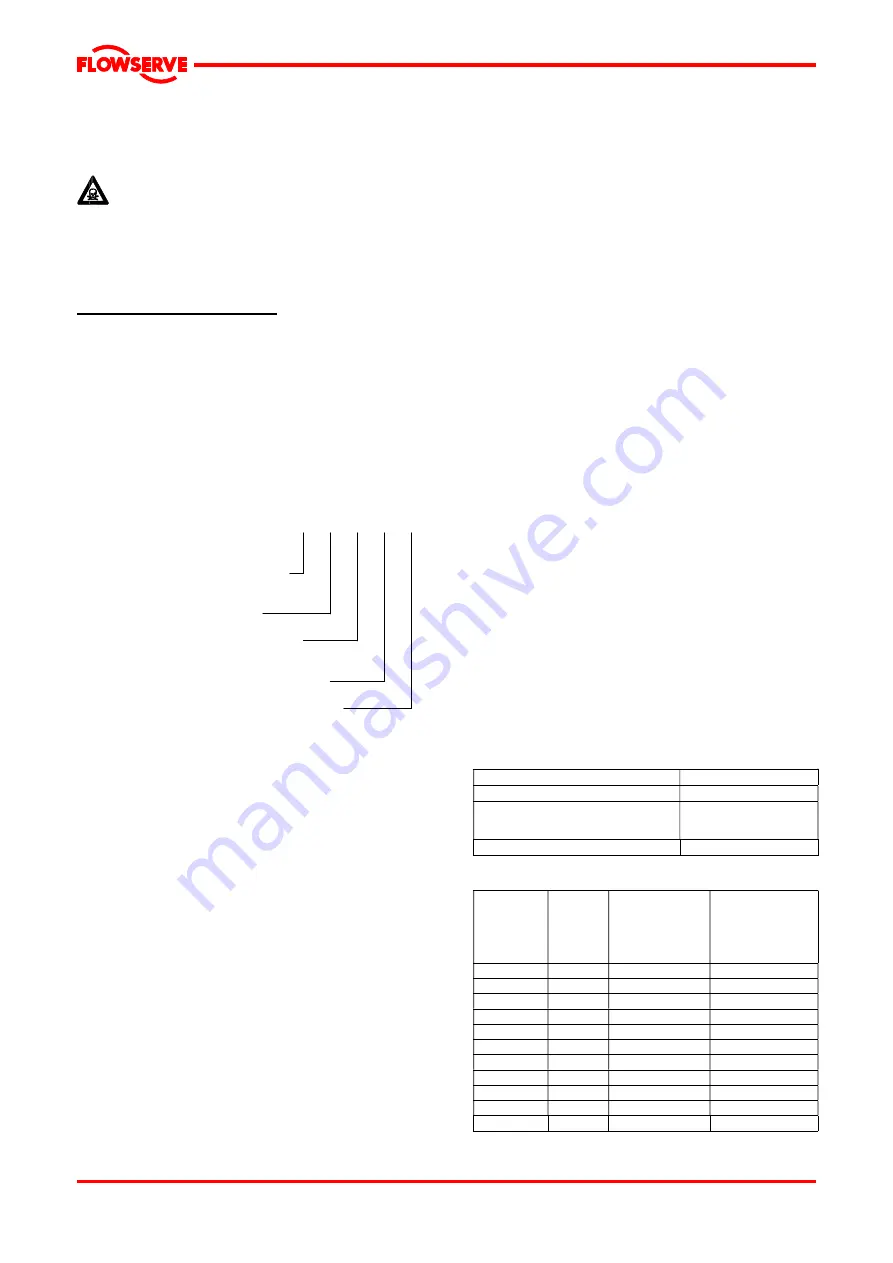

3.2 Name nomenclature

The pump size will be engraved on the nameplate

typically as below:

PVML 30-20-20-30F

Configuration – see 3.1 above.

Nominal impeller size (cm)

Nominal suction branch size (cm)

Nominal discharge branch size (cm)

Nominal max. impeller diameter & type.

The typical nomenclature above is the general guide

to the PVML configuration description. Identify the

actual pump size and serial number from the pump

nameplate. Check that this agrees with the applicable

certification provided.

3.3 Design of major parts

3.3.1 Pump casing

The pump has its main casing gasket axial to the shaft

allowing maintenance to the rotating element by

removing the back pull out unit. Suction and

discharge branches are at the casing and therefore its

piping remain undisturbed at maintenance.

3.3.2 Impeller

The impeller is fully shrouded and is fitted with

impeller wear rings.

3.3.3 Diffuser

The diffuser is tuned to the impeller and the multi

channel diffuser is concentric aligned around the

impeller

3.3.4 Extended Motor Shaft

The extended motor shaft, mounted on the motor

bearings is of the dry shaft design and has a keyed

drive end.

3.3.6 Stuffing box

The stuffing box has a spigot (rabbet) fit between

the pump casing and seal plate for optimum

concentricity. The design enables a number of

sealing options to be fitted.

3.3.7 Shaft seal

The mechanical seal(s) attached to the pump shaft

seals the pumped liquid from the environment.

Gland packing may be fitted as an option, for non-

hazardous service only.

3.3.8 Driver

The driver is an electric motor.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order. See section

1.5.

The following data is included as additional information

to help with your installation. It is typical, and factors

such as temperature, materials, and seal type may

influence this data. If required, a definitive statement

for your particular application can be obtained from

Flowserve.

3.4.1 Operating limits

Pumped liquid temperature limits*

up to +260 ºC (500 ºF)

Maximum ambient temperature*

up to +40 ºC (104 ºF)

Maximum soft solids in

suspension*

up to 1 % by volume

(refer for size limits)

Maximum pump speed

refer to the nameplate

3.4.2 Pump and impeller data

Pump size

Impeller

maximum

size

mm (in.)

Nominal wear

ring diameter

Small / large

mm (in.)

Min.

diametral

wear ring

clearance

mm (in.)

PVML 25.04.04 220 (8.66)

90/-- (3.54/--)

0.35/-- (0.014/--)

PVML 25.08.08 240 (9.45)

90/130 (3.54/5.12) 0.35/0.43 (0.014/0.017)

PVML 25.10.10 235 (9.25)

130/-- (5.12/--)

0.43/-- (0.017/--)

PVML 25.15.15 242 (9.53) 165/200 (6.50/7.87) 0.45/0.50 (0.018/0.020)

PVML 30.20.20 290 (11.42) 220/265 (8.66/10.43) 0.50/0.55 (0.020/0.022)

PVML 35.08.08 370 (14.57) 110/130 (4.33/5.12) 0.38/0.43 (0.015/0.017)

PVML 35.10.10 370 (14.57) 130/140 (5.12/5.51) 0.43/0.43 (0.017/0.017)

PVML 35.15.15 354 (13.93) 180/220 (7.09/10.43) 0.48/0.50 (0.019/0.020)

PVML 35.20.20 350 (13.78) 220/275(7.09/10.83) 0.50/0.58 (0.020/0.023)

PVML 40.10.10 420 (16.54) 130/140 (5.12/5.51) 0.43/0.43 (0.017/0.017)

PVML 40.15.15 420 (16.54) 220/275(7.09/10.83) 0.50/0.58 (0.020/0.023)

Page 10 of 29