PVML USER INSTRUCTIONS ENGLISH 00079591 – 01/05

®

�

Refer to the manuals of any associated

equipment for routine checks needed.

6.1.2 Periodic inspection (six monthly)

a)

Check foundation bolts for security

of attachment and corrosion.

b) Check pump running records for hourly usage to

determine if motor bearing lubricant requires

changing.

�

Refer to the manuals of any associated

equipment for periodic checks needed.

6.1.3 Mechanical seals

No adjustment is possible. When leakage reaches an

unacceptable level the seal will need replacement.

6.1.4 Gland packing

The stuffing box split gland can be completely

removed for re-packing or to enable the addition of

extra rings of packing.

The stuffing box is normally supplied with a lantern

ring to enable a clean or pressurised flush to the

centre of the packing. If not required, this can be

replaced by an extra 2 rings of packing.

There must always be a small leakage, normally a

minimum of 120 drops per minute to atmosphere to

lubricate and cool the packing is required.

6.2 Spare parts

6.2.1 Ordering of spares

Flowserve keep records of all pumps that have been

supplied. When ordering spares the following

information should be quoted:

1) Pump serial number.

2) Pump size.

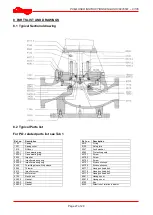

3) Part name – taken from section 8 and

relevant P.O. related parts list. (Tab 1)

4) Part number – taken from relevant P.O.

related parts list. (Tab 1)

5) Number of parts required.

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non-standard part) will

invalidate the pump’s safety certification.

6.2.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of metallic

surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

6.3 Recommended spares and

consumable items

For start up purposes (Initial spares):

1 - set of gaskets and seals

(optional: 1 - complete set of gland packing)

For initial stock (Normal spares):

1 - set of motor bearings (line and thrust)

1 - mechanical seal or set of seal faces

2 - sets of gaskets and seals

2 - casing wear rings

(optional: 2 - sets of gland packing

2 - shaft sleeves

2 - lantern rings

2 - impeller wear rings)

For 2 years operation:

1 - set of motor bearings (line and thrust)

1 - mechanical seal

2 - sets of gaskets and seals

2 - casing wear rings

2 - impeller wear rings

1 - impeller

1 - diffuser

(optional: 2 - sets of gland packing

2 - shaft sleeves

2 - lantern rings

2 - impeller wear rings)

6.4 Tools required

A typical range of tools that will be required to

maintain these pumps is listed below.

Readily available in standard tool kits, and

dependent on pump size:

•�

Open ended spanners (wrenches) to suit up to

M 48 screws/nuts

•�

Socket spanners (wrenches), up to M 48

screws

•�

Allen keys, up to 10 mm (A/F)

•�

Range of screwdrivers

•�

Soft mallet

More specialized equipment:

•�

Bearing pullers

•�

Bearing induction heater

•�

Dial test indicator

Page 19 of 29