PVML USER INSTRUCTIONS ENGLISH 00079591 – 01/05

®

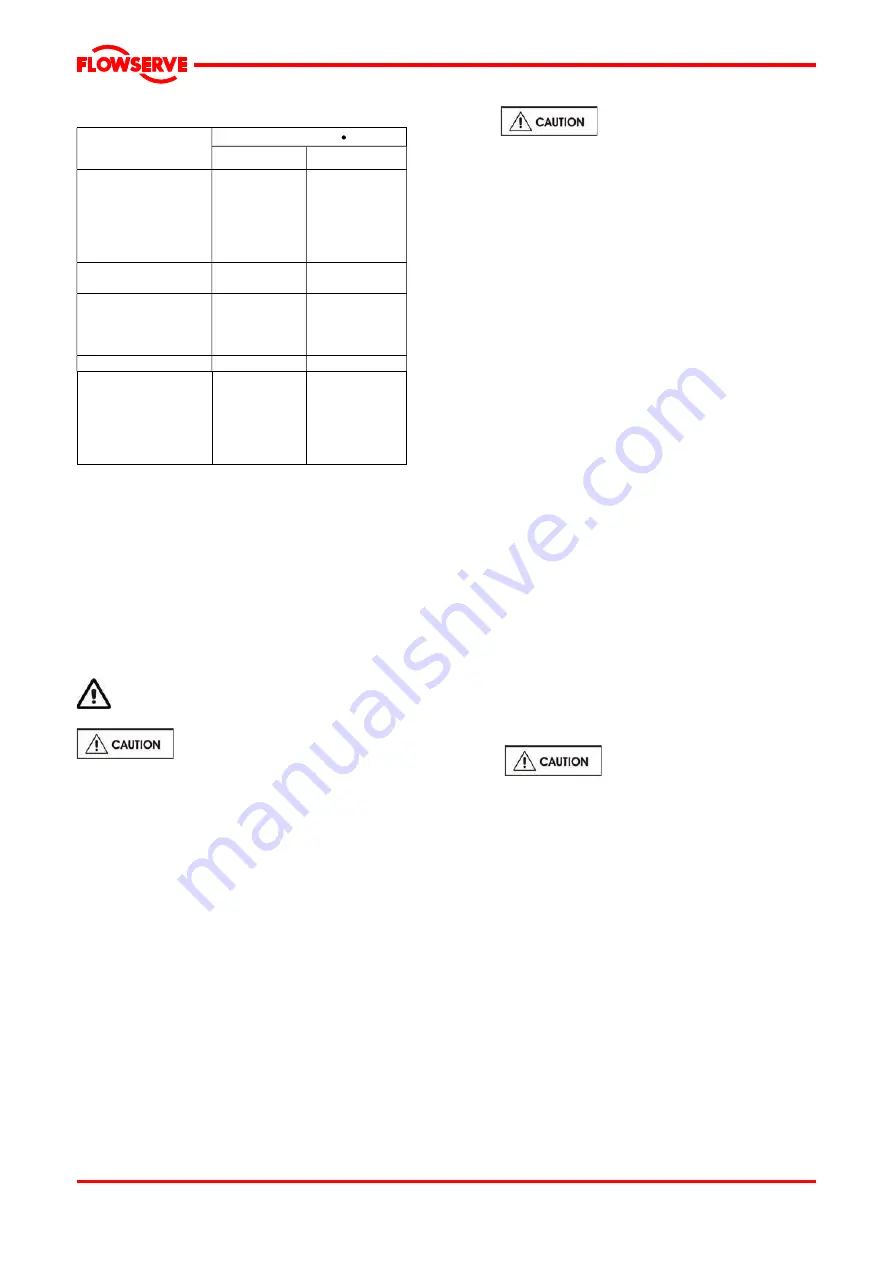

6.5 Fastener torques

Torque Nm (lb ft)

Application

Lubricated

Not lubricated

Casing studs

M 12

M 16

M 20

M 24

M 30

55 (41)

110 (81)

170 (126)

247 (182)

519 (383)

65 (48)

165 (122)

285 (211)

375 (277)

540 (399)

Seal studs, all cases

(back mounted seal)

125

145

Seal bolts

(front mounted seal)

M10

M12

25 (18)

34 (25)

30 (22)

40 (30)

Packed gland studs

Finger tight

Finger tight

Impeller screw

M8

M12

M16

M20

M24

6 (4.5)

23 (17)

57 (42)

114 (84)

180 (133)

7 (5.2)

25 (18)

60 (44)

120 (89)

190 (140)

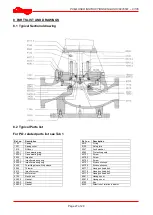

6.6 Setting impeller clearance

As wear takes place between the impeller and casing

ring the overall efficiency of the pump set will

decrease. To maintain optimum efficiency it is

recommended that rings are replaced and the impeller

renovated when the diametral clearance detailed in

section 3.4.2 has doubled to 0.7 to 1.1 mm (0.028 to

0.043 in.), depending on pump size and wearing ring

diameter.

6.7 Disassembly

Refer to section 1.6,

Safety

, before dismantling

the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawings for part numbers and

identification.

6.7.1 Removing the 'back pull out' unit

The 'back pull out' unit is removed by following the

procedure given below:

��

remove the nuts [6581.1] from the casing cover.

��

attach the lifting devices to the appropriate lifting

points, see Figure 1. Observe the lifting

instructions described in section 2.3.

��

lift the casing cover up. Work carefully as there is

not much clearance between the diffuser and the

pump casing.

��

remove the packing ring [4590.2] from the pump

casing and dispose of this in the proper way.

This type of packing may only

be used once.

6.7.2 Removing the diffuser

This procedure describes removal of the diffuser

from the casing cover.

��

Bend open the lock washers [6541] and

remove the hexagon head bolts [6577.1] from

the diffuser.

��

Remove the diffuser.

6.7.2 Removing the impeller

This procedure describes removal of the impeller

from the shaft of the electric motor.

��

fix the shaft sleeve of the mechanical seal in

place using the face plates on top of the cover

of the mechanical seal.

��

undo the impeller screw [2913] with left-hand

thread. The impeller screw is locked in the bore

hole in the impeller by twisting the impeller

screw.

��

remove the impeller screw and the packing ring

[4590.4] between impeller and impeller screw.

This type of packing may only be

used

once

. Dispose of the packing ring in the proper

way.

��

push the impeller from the shaft of the electric

motor and remove the released key [6700].

��

remove packing ring [4590.3] between the

impeller and the shaft sleeve of the mechanical

seal.

This type of packing may only

be

used once

. Dispose of the packing ring in

the proper way.

6.7.3 Removing the motor stool

With a 'back mounted' construction, the mechanical

seal is mounted on the top of the casing cover

which means that the motor stool has to be

detached from the casing cover before

disassembling the mechanical seal.

��

Place the bottom of the casing cover on a flat

surface.

��

Remove the bolts [6577.2].

��

Lift the motor stool up vertically. Work carefully

as long as the shaft of the electric motor is still

inserted in the shaft sleeve.

Page 20 of 29