R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 12 of 54

®

2.5 Recycling and end of product life

At the end of the service life of the product or its parts,

the relevant materials and parts should be recycled or

disposed of using an environmentally acceptable

method and in accordance with local regulations. If the

product contains substances that are harmful to the

environment, these should be removed and disposed of

in accordance with current local regulations. This also

includes the liquids and/or gases that may be used in

the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety specifications

must be in accordance with the current local

regulations at all times.

3 PUMP DESCRIPTION

3.1 Configurations

Flowserve "R Slurry" pumps are single stage, end

suction centrifugal pumps specifically designed for

handling abrasive slurries typical of mining and mineral

process. The casing is radially split with the gland side

casing pedestal mounted. The discharge is tangential.

The casings are fitted with removable rubber liners.

The closed impeller with rear pump-out vanes is

capable of passing solids of various sizes. Sealing is

provided at the impeller to shaft fit to prevent corrosion

and thereby facilitate impeller removal. The rigid three

point thrust bearing housing support permits precision

bearing alignment. Since the casing is pedestal

mounted, back pull-out is not a normal feature.

The pump is sealed using non-asbestos packing in the

stuffing box. An optional hydrodynamic seal,

commonly referred to as an expeller is available and

various mechanical seal designs as specified by the

customer may be installed at the factory or retrofitted in

the field.

All pumps are carefully inspected and prepared for

shipment. All exterior machined surfaces are coated

with a rust preventative compound and openings are

provided with covers or plugs. Shaft packing, when

required, is shipped with the pump and should not be

installed until the pump is ready to run. Mechanical

seals, when provided, are factory installed and adjusted

prior to shipment. The axial impeller running clearance

is preset at the factory but should be checked prior to

final alignment in case of tampering.

These User Instructions also cover the RX and RS

configurations, check the nameplate against the

nomenclature.

3.2 Name nomenclature

The pump size will be engraved on the nameplate. The

following example explains how the pump name

identifies the construction features and options.

8R-193

Nominal discharge branch size.

Configuration – see below.

Nominal maximum impeller diameter.

Frame size

R

is the basic pump type

X

is added for an expeller

3.3 Design of major parts

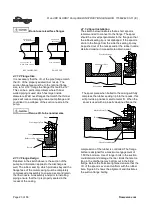

3.3.1 Pump casing

The pump casing is a semi-concentric volute type

casing and tangential discharge nozzle and is radially

split. The casing are cast iron and are pedestal

mounted therefore the discharge can be rotated to

meet a number of optional orientations. It is fitted with

replaceable rubber liners. The casing joints are self

sealed by the rubber liners however optional urethane

lined casing may require gaskets at some flange

connections. The casing flanges are also drilled and

tapped

3.3.2 Impeller

The impeller is a closed design as standard but may be

changed to open designs for mud, froth and viscous

applications. The impeller is thread mounted to the

shaft. All impellers are supplied with pump out vanes to

minimise wear and reduce pressure at the stuffing box.

The vanes are curved to optimize efficiency however,

the “S” configuration utilizes straight radial vanes to

reduce blockage. The impeller of the RS pump has

larger front clearances to reduce shear and improve

froth handling capabilities.

3.3.3 Shaft

The large diameter stiff shaft, mounted on bearings,

has a keyed drive end. The shaft extension at the

coupling is extended to cover multi-v-belt drives.

3.3.4 Pump bearings and lubrication

Ball bearings are fitted as standard and may be either

oil or grease lubricated.