R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 13 of 54

®

Oil lubrication is only available where the pump shaft is

horizontal. The bearings on frame 6 pumps (18R416)

can not be grease lubricated.

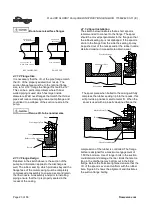

3.3.5 Bearing housing

For oil lubricated bearings, a bulls eye level gauge is

supplied. Constant level oilers can also be fitted. Two

grease nipples enable grease lubricated bearings to be

replenished between major service intervals.

3.3.6 Stuffing box housing

The stuffing box is a loose design and has a spigot

(rabbet) fit with the pump casing. The design enables a

number of sealing options to be fitted as well a wide

range of materials options.

3.3.7 Shaft seal

The mechanical seal(s), attached to the pump shaft,

seals the pumped liquid from the environment. Gland

packing may be fitted as an option. The “X” model is

fitted with an optional dynamic or expeller seal for

certain applications.

3.3.8 Driver

The driver is normally an electric motor. Due to the

hardness of the impeller the norm is to use multi-v-

belts. Different drive configurations may be fitted such

as internal combustion engines, turbines, hydraulic

motors etc driving via couplings, belts, gearboxes, drive

shafts etc.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order see section 1.5.

The following data is included as additional information

to help with your installation. It is typical, and factors

such as temperature, materials, and seal type may

influence this data. If required, a definitive statement

for your particular application can be obtained from

Flowserve.

3.4.1 Operating limits

3.4.1.1 Temperature

Liner Materials

Maximum Operating

Temperature

Natural Rubber-soft

65ºC (150ºF)

Natural Rubber-Hard

80ºC (176ºF)

Nitrile

93ºC (200ºF)

Neoprene

100ºC (212ºF)

3.4.1.2 Pressure

The maximum working pressure will be 110 PSIG for all

sizes except for the 18R416 which will be 100 PSIG.

Vacuum service should be avoided due to potential of

rubber liner collapse.

3.4.2 Speed torque curves

To bring a centrifugal pump up to rated speed, the

driver must be capable of providing more torque at

each speed than required by the pump. The margin

between the available and required torque affects the

time it takes the unit to reach full speed. If the torque

required by the pump exceeds the torque capability of

the drive at any run-up speed, the unit will not

accelerate to full speed. Normally, this is not a problem

with standard induction or synchronous motors

provided the proper voltage is supplied at the motor.

For pumps started at shut valve conditions, 100 percent

full speed torque can be calculated by using the

formula:

Torque (Nm) = 9545 Shutoff Power (kW)

r/min

Torque (ft.lb) = 5250 Shutoff Power (hp)

r/min

Torque required by the pump at any other speed during

start-up can be determined from the curve above. Note

that the driver manufacturer usually bases 100 percent

torque on the design power of the driver and

consequently the speed-torque curves should be

plotted in torque units (e.g. Nm) instead of percentage

torque to avoid confusion.