R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 21 of 56

flowserve.com

®

The length of extension rods should be kept at

a minimum to reduce deflection.

Rotate the pump shaft and record the dial reading at the

top, bottom and each side. Correct the parallel

alignment by adding or removing shims under the driver

and/or moving the driver horizontally. Repeat this

procedure until the maximum total indicator reading

(T.I.R.) is within 0.076 mm (0.003 inch.)

4.5.3.2 Angular Alignment:

Mount the magnetic base on the pump half coupling

hub, either the face or O.D. as shown in the sketch.

Move the dial indicator button to indicate on the face of

the driver half coupling hub as close to the outside

diameter as possible. When convenient the indicator

can be placed on the inside face to keep spans short.

Turn both shafts 360

and record the dial readings at

90

intervals. Adjust the shims under the motor as

required and repeat the procedure until the angular

alignment is within 0.0005 mm (T.I.R.) per mm (0.0005

inch per inch) of maximum hub diameter.

Checking angular misalignment

Repeat the checks on parallel and angular alignment,

ensuring the mounting bolts are secure, until the unit is

properly aligned. Note that correction in one direction

may affect the alignment in another direction. Re-check

the gap between the coupling hubs.

If any difficulty is encountered in achieving the

recommended alignment tolerances, the runout of the

pump and driver shafts and each coupling hub diameter

and face should be checked. Occasionally, due to

practical and unavoidable manufacturing tolerance

build-up associate with the pump, coupling and driver, it

may be necessary to match up the two coupling hubs in

the most advantageous relative angular position in order

to achieve an acceptable alignment.

Do not install the coupling spacer or sleeve until

grouting is complete and cured and the alignment is re-

checked.

When the electric motor has sleeve bearings it is

necessary to ensure that the motor is aligned to run

on its magnetic centreline. A button (screwed into

one of the shaft ends) is normally fitted between the

motor and pump shaft ends to fix the axial position.

If the motor does not run in its

magnetic centre the resultant additional axial force

may overload the pump thrust bearing.

Complete piping as below and see sections

4.7,

Final shaft alignment check

up to and including

section 5,

Commissioning, startup, operation and

shutdown

before connecting driver and checking

actual rotation.

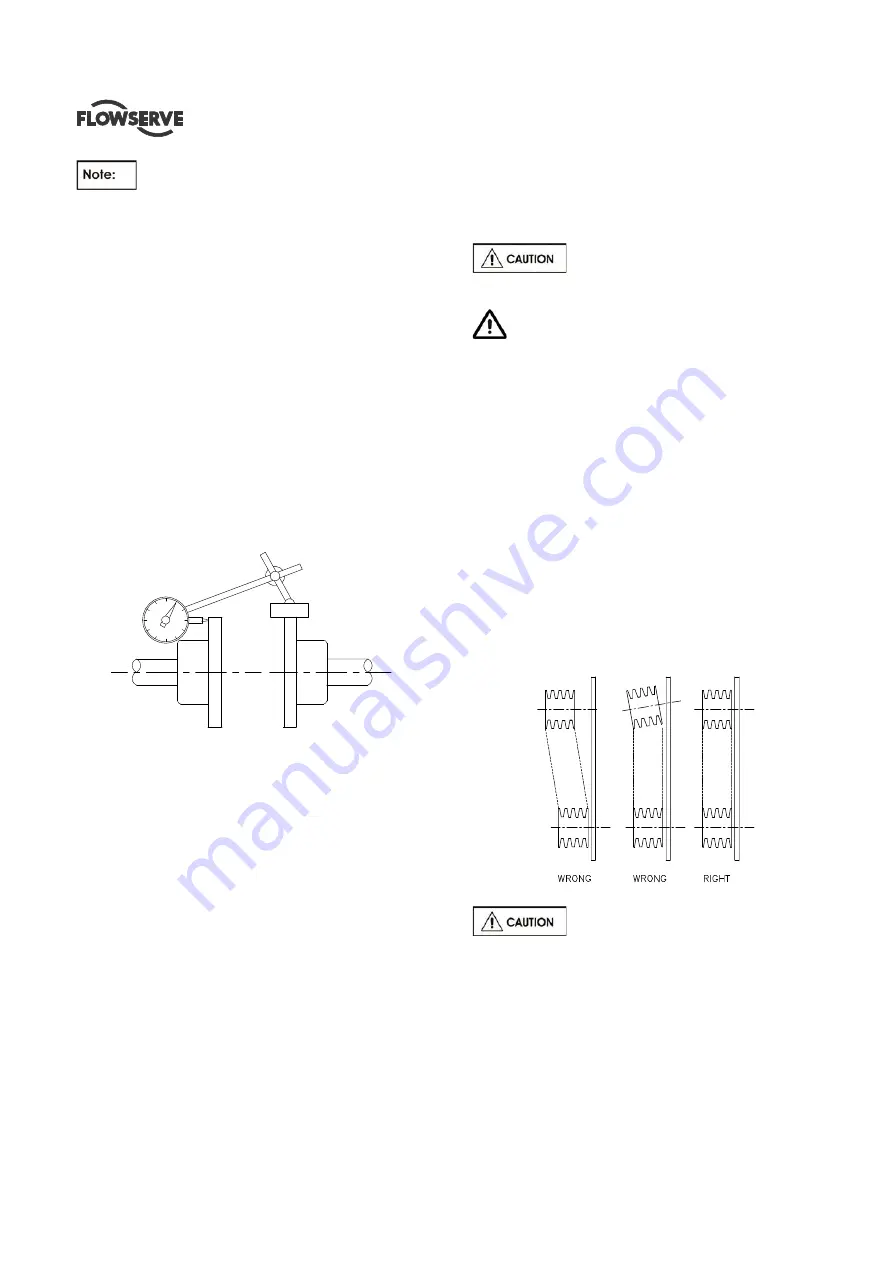

4.5.4 V-Belt Drive Units:

Check that both sheaves are free of grease, rust, nicks

or burrs. Install the correct size sheave on the pump

shaft and locate the sheave axially to minimize

overhang. Re-check the impeller axial clearance and

ensure that the pump is properly secured to the

baseplate. Install the driver on the adjustable base

provided and install the driver sheave in line with the

pump sheave. Ensure that the sheaves are tight on the

shafts. With a dial indicator, check the runout on the

periphery and face of each sheave to ensure that each

is running true. Tighten the adjustable base and check

that the driver rotation in the correct direction and that

vibration levels are not unacceptable.

Checking V-Belt Sheave Alignment

Before starting the driver, refer to the

manufacturer’s instruction manual. The correct rotation

of the pump shaft is marked on the pump casing or

frame.