R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 22 of 56

flowserve.com

®

Check that all belts making up one drive set have

matched code numbers. Loosen the adjustable base

and install the belts in their proper grooves. Adjust the

center distance between the sheaves to obtain proper

belt tension. Check the alignment of the pump and

driver sheaves with a taught string or straight edge. For

proper alignment and the sheave faces must be parallel

to each other and in line. Adjustments are made by

slackening the belts and moving the sheaves. Retighten

the drive or driver sheave then recheck. The procedure

may need to be repeated to get alignment as close as

possible..

When the sheaves are aligned that the shafts rotate

freely by hand and install safety guard.

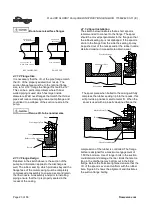

4.6 Grouting

The purpose of grouting is to provide rigid support to the

pump and driver by increasing the structural rigidity of

the baseplate and making it an integral mass with the

foundation.

Clean the roughed foundation surface and build a

wooden form around the baseplate (see Fig. 1). For

initial grouting forms should be placed to isolate shims

and levelling nuts. The foundation surface should be

thoroughly saturated with water before grouting. A

typical mixture for grouting-in a pump base is composed

of one part pure Portland cement and two parts of clean

building sand with sufficient water to provide the proper

consistency. The grout should flow freely but not be so

wet as to cause the sand and cement to separate.

Thoroughly puddle the grout while pouring to eliminate

air pockets and low spots. Pour sufficient grouting to

ensure that the bottom surface of the baseplate is

completely submerged. Do not fill isolated areas

around the shims or levelling nuts. Once the grout has

set sufficiently, remove the wooden forms and finish off

the sides and top as desired. At the same time,

roughen the grout surface inside the baseplate. Cover

with wet burlap and allow the grout to cure for at least

40 hours.

After grouting has cured, shims and levelling nuts

should be removed or backed off. Tighten down

baseplate to the new grout to put bolts in tension and

ensure rigidity of structure. Install jam nuts and cut the

bolts to the desired length. Finish grouting isolated

areas. Fill the baseplate including pump and driver

support pedestals with concrete. Trowel and slope the

surface to give suitable drainage.

4.7 Piping

Protective covers are fitted to the pipe

connections to prevent foreign bodies entering during

transportation and installation. Ensure that these

covers are removed from the pump before

connecting any pipes.

4.7.1 Suction and discharge pipework

In order to minimize friction losses and hydraulic

noise in the pipework it is good practice to choose

pipework that is one or two sizes larger than the

pump suction and discharge. Typically main

pipework velocities should not exceed 2 m/s (6 ft/sec)

suction and 3 m/s (9 ft/sec) on the discharge.

Take into account the available NPSH which must be

higher than the required NPSH of the pump.

Never use the pump as a support for

piping.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. To

minimize these forces and moments that may, if

excessive, cause misalignment, hot bearings, worn

couplings, vibration and the possible failure of the

pump casing, the following points should be strictly

followed:

Prevent excessive external pipe load

Never draw piping into place by applying force to

pump flange connections

Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange

The table in 4.7.2 summarizes the maximum forces

and moments allowed on M pump casings. Refer to

Flowserve for other configurations.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal of the pump.

4.7.1.1 Flange Facing

R Pumps are designed so that the connecting pipes

at the suction and discharge can be attached without

gaskets. To ensure correct sealing and rubber pinch,

standard flat face weld neck flanges must be used.

Any arrangements other than that shown will affect

pump internal clearances, cause leakage at the

flanges or result in serious damage to the rubber

parts.