R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 23 of 56

flowserve.com

®

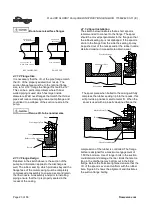

Do not use raised face flanges

RECOMMENDED

DO NOT USE

WELD NECK

-NO RAISED FACE

EQUIVALENT TO

WELD NECK FLANGE

WELD NECK

-RAISED FACE

SLIP-ON FLANGE

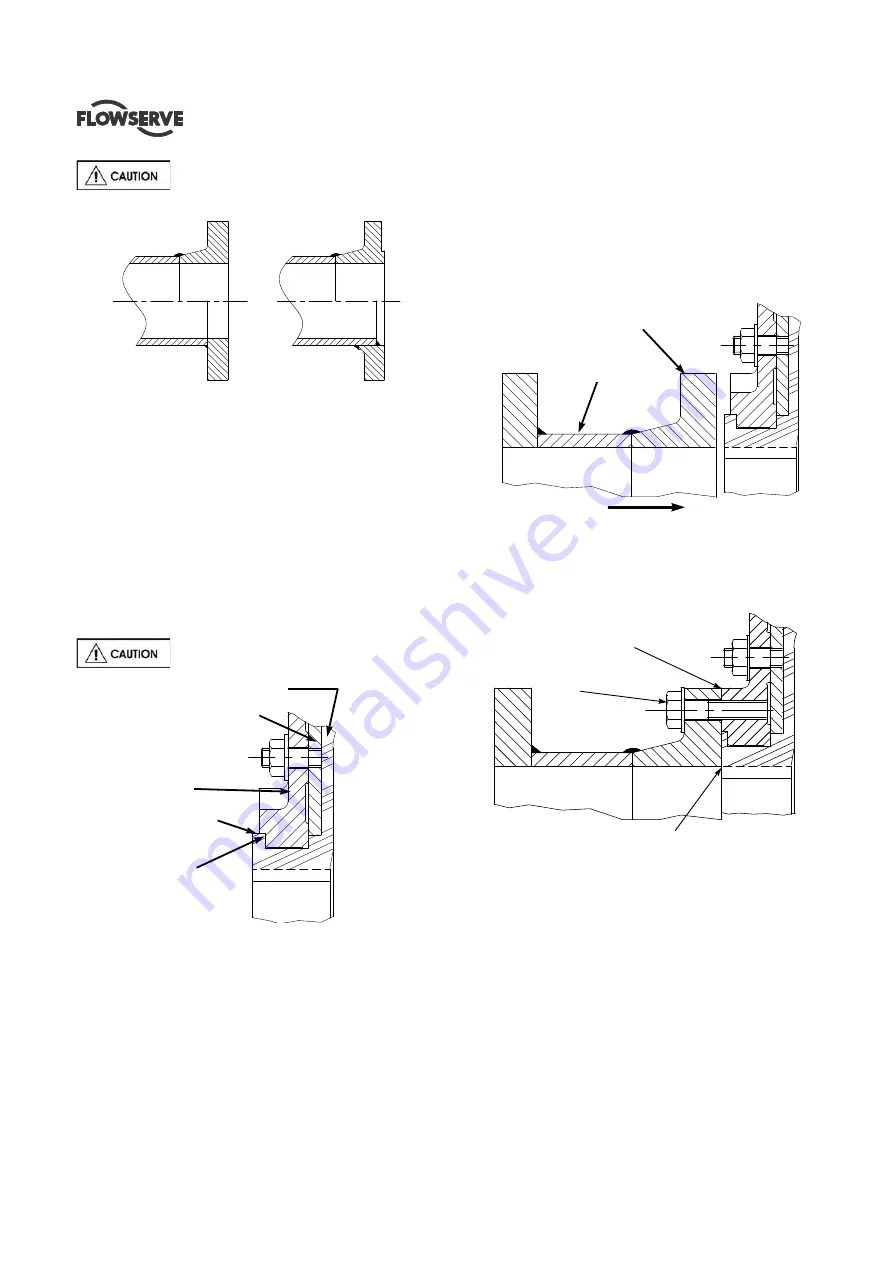

4.7.1.2 Flange Size

It is necessary that the I.D. of the pipe flange match

the I.D. of the properly seated liner nozzle. The

suction flange face must be to the nominal flange

size, ie for a 12” flange the flange ID should be 12”.

This can be a particular problem where thinner

walled piping is used which has larger inside

diameters. Weld neck flanges that match the thinner

pipes will reduce clamping area at pump flange and

could lead to a collapse of the suction nozzle in the

pump.

Flange I.D. to be nominal size

.

Liner

Liner support plate

Casing

Rubber seal lip extension

Recess

4.7.1.3 Flange Design

Depicted in the sketch above is the suction of the

pump but information applies to the discharge as

well. The rubber seal lip, which protrudes beyond the

flange face of the metal casing must be completely

compressed at assembly to ensure a seal and retain

the liner nozzle. At assembly and prior to installing

piping ensure that the lip is properly seated in the

recess of the casing.

4.7.1.4 Spool Installation

The sketch below illustrates that a short spool is

recommended to connect to the flange. The spool

should be moved perpendicular to the flange so that

the rubber sealing lip is not dislodged. If the spool is

slid into the flange from the side the sealing lip may

be pushed out of the recess and/or the rubber nozzle

distorted making it impossible to obtain a seal.

Movement

Flat faced flange

Short Spool Piece

The spool piece when bolted to the casing will fully

compress the rubber sealing lip into the recess, this

will provide a positive metal to metal fit. When the

spool is used with a properly designed flange the

Check for uniformity

Bolt

Metal to Metal Fit

compression of the rubber is controlled. The flange

bolts are designed for a maximum engagement of

1.5X the bolt size. Use of longer bolts in the suction

could distort and damage the liner. Bolts that are too

long in the discharge may bottom out in the blind

flange. Before the bolts are tightened ensure that the

I.D. of the spool is even and uniform with the rubber

bore. Figure 8C shows the alignment and illustrates

the suction flange bolting.