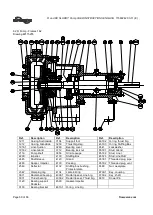

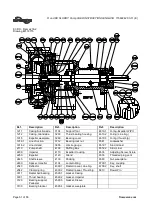

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 36 of 56

flowserve.com

®

a) On small pumps the impeller can be removed and

held by hand however, larger units will require that a

hoist be used to lift the impeller. Place a sling

through the impeller vanes.

b) Remove the impeller [2200].

6.8.1.3 Expeller Pumps Only

a) Place a sling around the expeller housing.

b) Remove c-clamp

c) Remove expeller [2250].

d) Remove expeller wearplate [1915].

e) Remove stuffing box head [4100].

All pumps except expeller option

6.8.2 Stuffing box

6.8.2.1 Shaft seal - gland packing

a) Remove gland nuts and gland halves [4120]

b) Remove gland packing rings [4130] and lantern

rings [4134] using a bent wire.

6.8.2.2 Shaft seal - mechanical seal

Refer to any special instructions supplied with

the mechanical seal.

a) Remove seal cover screws and pull off seal cover

complete with the stationary seal ring that is held in

place by the O-ring seal.

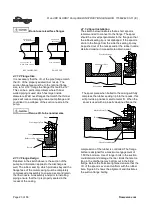

b) The mechanical seal cover can also be removed by

placing a wedge into the gland chamfer, as below:

6.8.3 Shaft sleeve

a) Remove the impeller spacer [2460] and shaft sleeve

gasket.

b) Remove the shaft sleeve [2445] if scored or worn.

6.8.4 Bearing housing

a) Remove the deflector [2540] and the line bearing

cover [3260].

b) Remove the pump half coupling and coupling key

[6700].

c) Remove the bearing frame support [3134] and

OHMM if applicable.

d) Lift the bearing frame assembly into a vertical

position with the thrust bearing housing [3230] up.

Rest the bearing frame flange on heavy wooden

blocks sufficiently high to ensure end of the shaft

does not come into contact with the floor or table.

e) Remove the thrust bearing hold down bolts and

remove shaft assembly for the bearing frame [3130].

6.8.5 Line bearing

a) Lay the shaft [2110] horizontal and support with

wooden ‘V’ Blocks.

b) Only if necessary remove the line bearing [3011]

from the shaft. Bearings removed can easily be

damaged and undetected until pump is put back in

operation.

6.8.6 Thrust bearings

a) Lay the shaft [2110] horizontal and support with

wooden ‘V’ Blocks.

b) Remove the thrust bearing clamp ring [2542] from

the thrust bearing housing [3230].

c) Remove the thrust bearing housing [3230].

d) Bend up the locking tab on the bearing lockwasher

[6541] and remove the bearing locknut [3712] and

lockwasher [6541].

e)

Only if necessary remove the thrust bearings [3031]

from the shaft. Bearings removed and reused can

easily be damaged and undetected until pump is put

back in operation.

On frame 6 there are springs to preload the

thrust bearings. These must be removed as the

bearings are removed.

6.8.7 Gland side Liner (if necessary)

There are 2 sets of studs. The inner ring secures the

stuffing box to the casing and the outer ring secures

the liner to the casing. nuts and washers.

a) Place the gland side casing on a clean work

surface resting on the large flange.

b) Remove the inner ring of hex nuts that secure the

stuffing box [4132] to the casing [1212]

c) Remove the loose box from the casing.

d) Remove the Protector plate [4132] from the bore

of the casing.

e) Remove the outer ring of nuts that secure the

glandside liner [1916.2] to the glandside casing

[1D].

f) If necessary use wood blocks on the studs or

center portion to dislodge the liner.

g) Lift the casing away from the liner