R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 42 of 56

flowserve.com

®

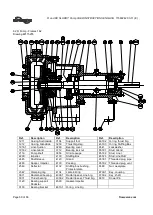

6.10.6.6 Optional expeller seal-frame 3 & 4

f) Assemble the stuffing box [4100] over the sleeve

[2445] and into the bearing frame [3130] register.

Orient the grease fitting to suit the installation. Note

that if the optional solid gland with lip seal design is

used, it must be installed first.

g) Install O-ring onto the expeller stuffing box

groove. Install expeller wearplate [1915] onto the

stuffing box.

Some units may be built with a 1 pc stuffing

box/wearplate. In this cause this step will be

eliminated.

h) Install the expeller [2250] over the shaft sleeve.

Expeller should seat against the sleeve shoulder

but be clear of the expeller wearplate [1915].

Adjust the shaft [2110] forward to ensure that the

expeller [2250] when installed will not bind against

the stuffing box head [4100].

i) Install gasket [4590] over expeller to face of

stuffing box [4100].

j) Install expeller housing [4110] to stuffing box

[4100], clamp in place.

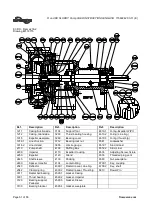

6.10.6.7 All Expeller fitted Units

a) The face of the expeller housing [4110] has a

recess cut that seats against the gland side liner.

To assist with sealing apply a bead of silicone to

this recess.

b) Lift casing [1212] and liner and install over the

expeller housing [4110].

c) Secure to pedestal [3120].

6.10.7 Impeller Installation-all pumps

a) Install the impeller gasket [4590] on all pumps.

b) Install the impeller spacer [2460].

c) Due to the method of assembling the impeller, it is

recommended to smear the sleeve face and both

sides of the impeller spacer [2460] with a heavy

grease or a silicon sealant before assembling onto

the shaft which will help to hold the impeller spacer

in position during assembly.

d) Apply anti-seize compound to the shaft threads and

screw the impeller onto the shaft. For large sizes it

is more practical to hold impeller using a sling and

hoist and turn the shaft.

Failure to tighten the impeller [2200]

spacer [2460] securely against the sleeve may

cause serious damage to pump components.

The thread is designed so that during

operation the impeller will tend to tighten onto shaft.

Therefore a clockwise shaft rotation (looking from

coupling end) will screw impeller on.

e)

Release the thrust bearing housing hold down bolts

and tighten the jacking screws to pull the impeller

back to the stuffing box head [4100]. The stuffing

box head must not be rigidly clamped.

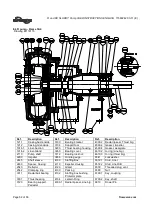

6.10.8 Suction Side Liner

6.10.8 1.25R090

a) Place casing [1211] on clean work surface with

the casing resting on the suction flange.

b) Lift liner in install into casing.

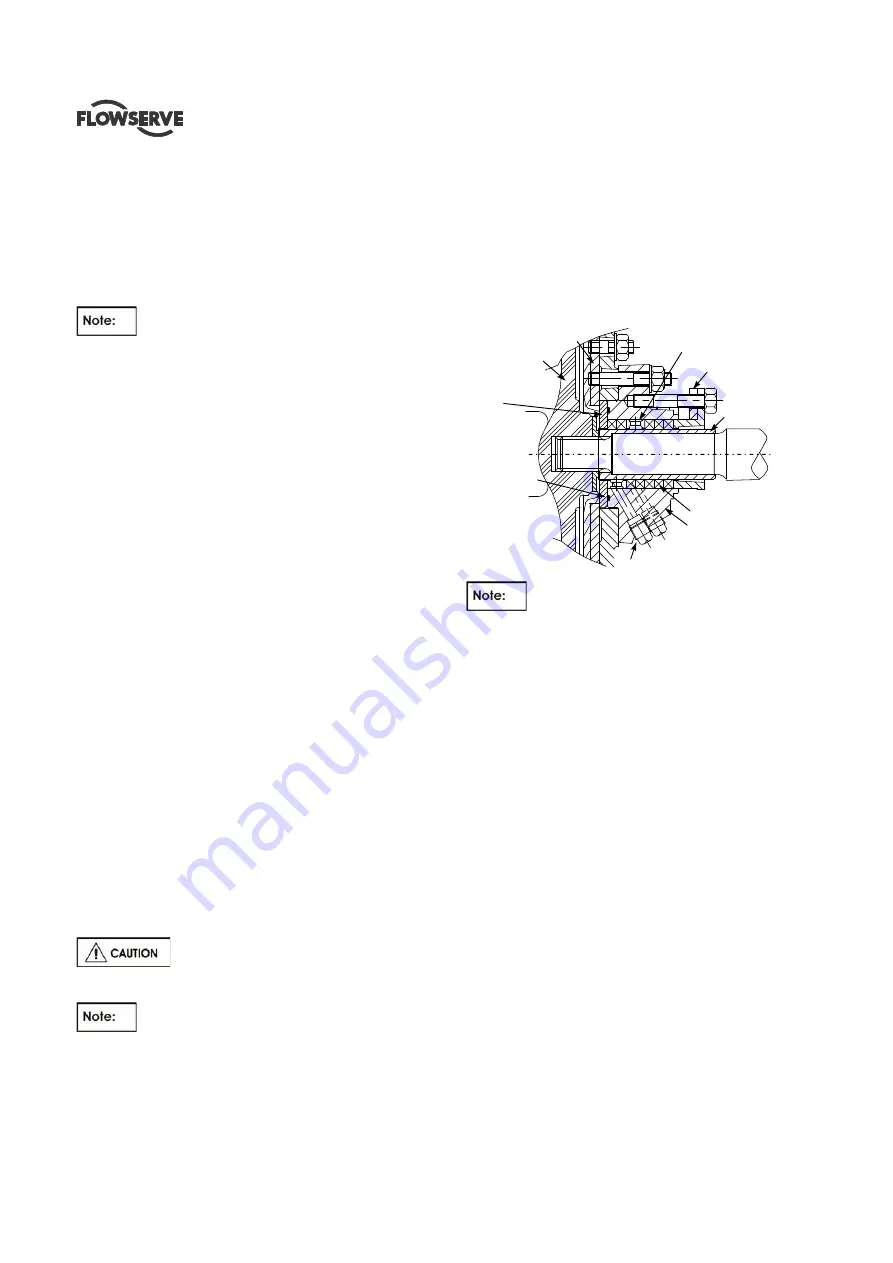

IMPELLER (2)

GLAND SIDE LINER (223)

4 LANTERN RING CONNECTIONS

2 FOR EACH PACKING ARRANGEMENT

SPLIT GLAND (17)

PROTECTOR PLATE

(185)

O-RING (89C)

SHAFT SLEEVE (14)

PACKING (13)

LANTERN RING (29)

STUFFING BOX (83)

OPTIONAL ARRANGEMENT (2L3)

RECOMMENDED ARRANGEMENT (L5)

The 1.25R090 does not use bolts to hold the

liner in place.

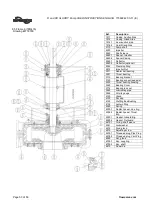

6.10.8.2 12R264 and 18R416 with 2 pc liner

a) Place the suction side liner [1916] for 2 pc liners on

12R264 and 18R416] on a clean work surface with

support plate (stud holes exposed)

b) Install the studs [6572] in the suction side liner

[1916.1] using Loctite grade A or equivalent.

c) Smear the suction nozzle and volute wall with a

liquid soap (do not use petroleum product as it

can swell some rubbers.

d) Lift suction side casing [1211] and install over liner

[1916]. The sealing lip of the suction nozzle must

be pried into position. Use a blunt pry bar in a way

similar to installing a tire on a rim. Once nozzle is

in place, fasten liner.

6.10.8.3 All Sizes 2.5 and larger

a) Place the Suction side inner liner [1916] on a clean

work surface and elevate such that back of the liner

is higher then volute depth of the outer liner [1916]

b) Install studs into liner [1916].

c) Smear the suction nozzle and outside diameter of

the liner with a liquid soap (do not use petroleum

product as it can swell some rubbers.

d) Lift suction side casing [1211] and install over liner

[1916]. The sealing lip of the suction nozzle must

be pried into position. Use a blunt pry bar in a way

similar to installing a tire on a rim. Once nozzle is

in place, fasten liner.