R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 43 of 56

flowserve.com

®

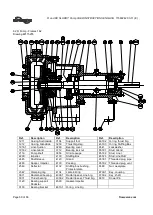

6.10.9 Casing

a) Install dowel pins in gland side casing.

b) Lift the suction side casing [1211] and assemble to

the gland side casing [1212].

c)

Pumps with 8” discharge and larger use spacers

between the casing halves. Install mounting

hardware.

spacers required for pumps 8” and larger

d) Secure into position. Ensure that the impeller is free

to rotate before torquing bolts.

e) Set the impeller front clearance in accordance with

instruction earlier in this section of the manual.

6.10.10 Shaft seal

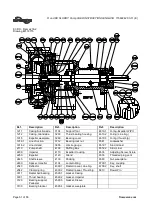

6.10.10.1 Packing

a)

The two piece lantern ring [4134] must be installed

first for standard L5. Push the lantern ring and

previously installed packing. The ports in the lantern

ring do not need to be aligned with the inlet/outlet

ports.

b)

Insert one packing ring at a time into the stuffing box.

Push the packing as far as possible into the packing

bore.

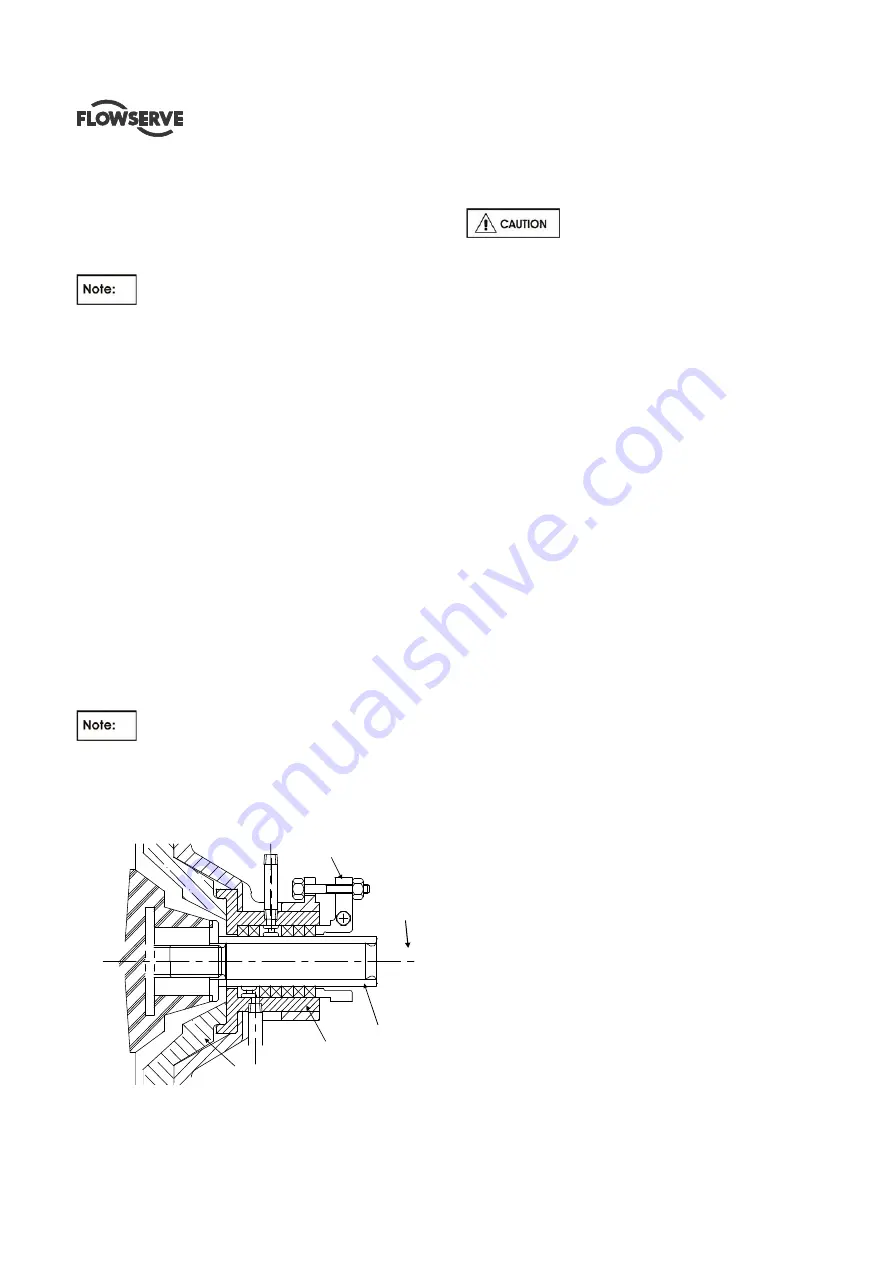

Standard Packed Box Arrangement (frame 1-4)

c)

Install additional rings as required, staggering the

joints.

d)

Ensure that the shaft can be turned by hand.

e)

Install the remaining rings of packing, alternating the

joints.

It may not be possible to insert the last ring in

the box and still insert the gland. In this case, omit the

last ring of packing and install the gland.

The last ring of packing should be installed after the

pump has been in service and sufficient space is

available.

2L3 packing arrangement

L5 packing arrangement

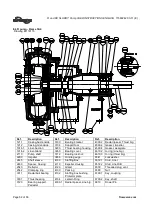

Gland-17

Bushing-83

Nipple-127

Gland Side Casing-1D

Sleeve-14

Shaft -6

Standard Packed Box Arrangement (1.25R090)

f)

Install the gland halves [4120], tighten the gland nuts

[6580] only finger tight.

N

ew packing has to be run-in and it is

good practice to start the pump with the stuffing box

gland quite loose. Packing that is too tight in the box will

cause undue friction, creating heat which will glaze the

packing and possible score the shaft sleeves. To be

effective, the packing must remain soft and pliable. If

stuffing box friction is so great that the pump shaft cannot

be turned by hand, the box is not properly packed.

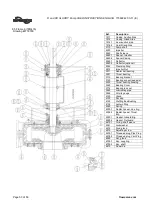

6.10.10.2 Mechanical seal

These details are specific to non-cartridge

seals therefore they may not apply. Refer to any

special instructions supplied with the mechanical seal.

a) Before the mechanical seal can be installed, the

pump must be assembled with the correct impeller

running clearances (ie: all assembly steps above). A

scribe mark is then placed on the circumference of

the sleeve to mark the end of the box. This mark is

used to locate the seal position referenced by the

mechanical seal drawing provided.

b) After scribing the sleeve, remove the rotating

element from the casing. Do not adjust the bearing

housing.

c) Remove the impeller [2200] and glandside casing

[1212]. Assemble the mechanical seal components,

including gland plates, gaskets and rotating parts

over the sleeve. Locate the seal relative to the

scribed markings on the shaft sleeve [2445] as

indicated by the seal manufacturers’ instruction.

d) Assemble the mechanical seal gland plate and

gasket and fasten using gland studs [6572]. Secure

with nuts [6580] and tighten each by hand. Further

tighten the nuts in accordance with Table in 6.6.

Rotate the shaft to ensure that it turns freely without

rubbing or binding.

e) Re-assemble the rotating element into the casing.

Do not adjust the thrust bearing housing.

f) Set the deflector [2540] at the line bearing cover

[3260] so that they do not contact when the shaft is

rotated. Lock in place with the setscrews provided.

6.10.11 Final assembly

a) Lift the assembled pump onto the baseplate and

position the casing feet over the tapped holes in the

baseplate.

b) On frame sizes 1 to 4, loosen the bolts that attach

the rear support foot [3134] to the bearing frame

[3130]. Level the unit and align with the piping.

Tighten the bolts attaching the casing feet to the

baseplate in accordance with Table 6.6 using for

tightening torques. Do not distort casing or frame.

c) Install the pump coupling or sheave as required.

d) Refer to Section 4, Installation and Section 5,