R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 44 of 56

flowserve.com

®

Preparation for Operation.

e) It is recommended that the pump not be packed until

required. Refer to stuffing box packing procedure in

this section. Protect the stuffing box bore and seal

area with clean dry rags.

6.11 Impeller axial clearance adjustment

This procedure should not be used on units

with mechanical seals if the design is such that a

liquid seal cannot be maintained when the rotor is

moved axially against the liners.

A blind flange must be installed on the

suction to compress the liner nozzle as it will be in

service. If this is not done clearance could be lost

cause impeller to rub against the liner causing

damage to pump components.

NEVER ATTEMPT TO CHANGE THE

CLEARANCE WHEN THE PUMP IS RUNNING.

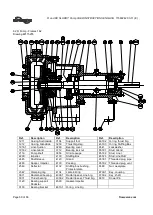

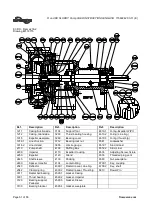

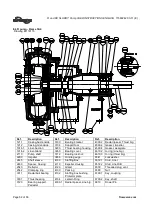

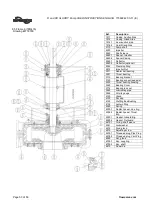

6.11.1 Frames 1-4

If the coupling has limited axial adjustment capability,

the pump and driver must be uncoupled prior to

adjusting the clearance in order to permit free

movement.

Install blind flange or pipe spool on

suction.

a) Loosen the two set screws retaining the deflector

[2540] and check that the deflector is free to move

axially on the shaft.

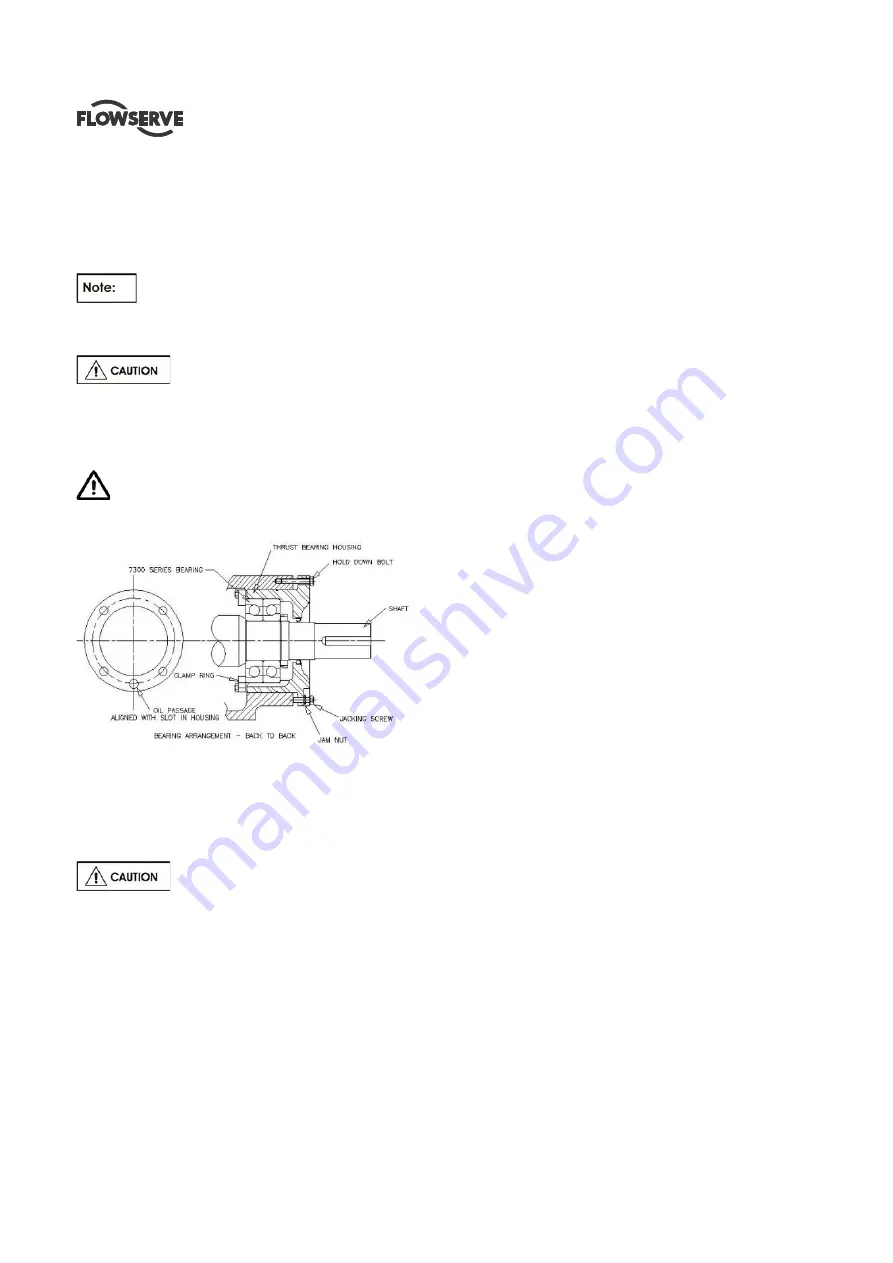

b) Loosen the thrust bearing housing jam nuts and

back off the three jacking screws at least 1.5 mm

(0.060 inch).

c) Move the rotor towards the suction side liner

[1916.1] by tightening the three hold-down

capscrews evenly and uniformly until the impeller

[2200] just touches the wear plate. This can be

best established by rotating the shaft and stopping

the forward motion at the first sign of rubbing. If

the shaft cannot be rotated, back off the bearing

housing with the jacking screws until a just

detectable rub is obtained. Check that the gap

between the two machined faces of the thrust

bearing housing [3230] and the bearing frame

[3130] are parallel within 0.076 mm (0.003 inch).

Adjust the jack screws and hold down capscrews

as required to achieve this parallelism. When the

impeller [2200] just touches the wear plate [1915]

and the thrust bearing housing [3230] is parallel to

the bearing frame [3130] the axial clearance

between the impeller and wear plate is zero.

6.11.1.1 Option1

a) Place a dial indicator, set to end of shaft [2110] or

on housing [3230] face.

b) Set indicator reading to zero (0).

c) Note required impeller clearance.

6.11.1.2 Option 2

a) Measure and record the axial gap between the

thrust bearing housing flange and bearing frame

end face. Determine the required impeller axial

running clearance from Section 3 and add this to

the above measurement to establish the required

gap setting.

6.11.1.3 Setting Axial Clearance

a) Loosen the thrust bearing housing hold down

capscrews slightly and tighten the jack screws.

Until the required dial indicator reading (6.11.1.1)

or housing gap reading (6.11.1.2) is achieved.

b) Alternately and gradually tighten the hold down

capscrews and jack screws until the required gap

setting is achieved at each hold down capscrew

location. Note that the gap at each jack screw will

be slightly larger as a result of minor elastic

distortion of the thrust bearing housing flange

caused by the high pre-load forces. The gap

setting at any set of screws must be the same

within 0.076 mm (0.003 in.). Careful attention to

this procedure will help ensure long thrust bearing

life.

c) While preventing the jack screws from rotating,

tighten the jam nuts to lock them in position.

d) Adjust the axial position of the deflector [2540] so

that it is clear of the line bearing cover [3260] by

approximately 0.75 mm (0.030 in.) and tighten the

setscrews firmly. Excessive tightening may mar

the shaft.

e) Manually rotate the shaft to ensure that there is no

rubbing or binding.

f) On belt driven units, adjust the pump or driver

sheave to maintain belt alignment. (Refer to

Section 4.5.2.2).

g) Check the alignment on direct driven units (refer