R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH

71569242 03-11 (E)

Page 45 of 56

flowserve.com

®

to Section 4) and reassemble the coupling

components.

h) Replace any safety guards which may have been

removed.

6.11.2 Frame 0

If the coupling has limited axial adjustment capability,

the pump and driver must be uncoupled prior to

adjusting the clearance in order to permit free

movement.

Install blind flange or pipe spool on

suction.

a) Slide the rubber deflector [2540] away from the

face of the bearing frame.

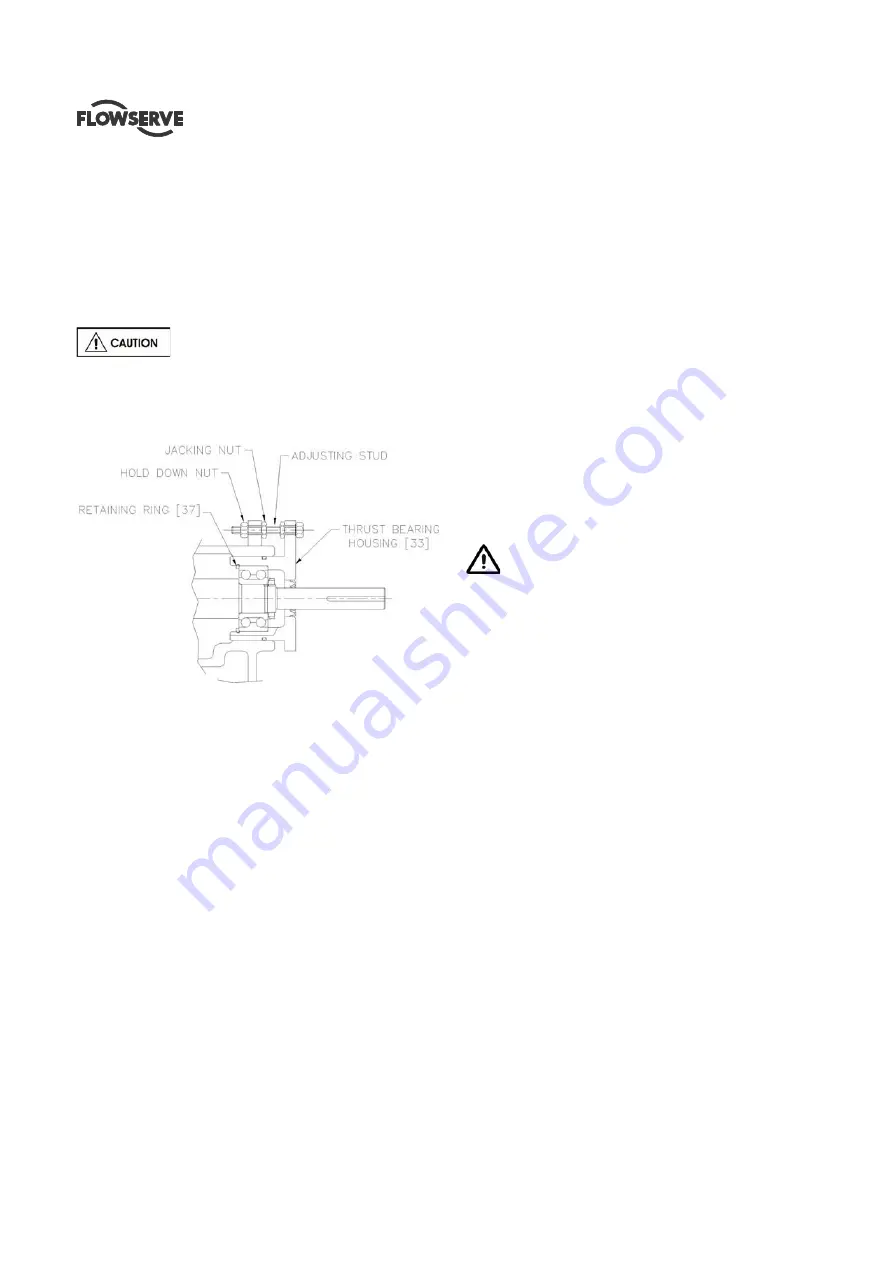

b) Loosen the thrust bearing housing Jacking Nut.

c) Move the rotor towards the suction side liner

[1916.1] by tightening the hold-down nut until the

impeller [2200] just touches the suction side liner

[1916.1]. This can be best established by rotating

the shaft and stopping the forward motion at the

first sign of rubbing. If the shaft cannot be rotated,

back off the bearing housing with the jacking

screws until a just detectable rub is obtained.

When the impeller [2200] just touches the suction

side liner [1916.1] the axial clearance between the

impeller and wear plate is zero.

6.11.2.1 Option1

d) Place a dial indicator, set to end of shaft [2110] or

on housing [3230] face.

e) Set indicator reading to zero (0).

f) Note required impeller clearance.

6.11.2.2 Option 2

b) Measure and record the axial gap between the

thrust bearing housing flange and bearing frame

end face. Determine the required impeller axial

running clearance from Section 3 and add this to

the above measurement to establish the required

gap setting.

6.11.2.3 Set Axial Clearance

d) Loosen the thrust bearing housing hold down nut

slightly and tighten the jacking nut. Until the

required dial indicator reading (6.11.2.1) or

housing gap reading (6.11.2.2) is achieved.

e) Tighten the hold down nut.

d) Adjust the axial position of the deflector [2540] so

that it is clear of the line bearing cover [3260] by

approximately 0.75 mm (0.030 in.)

e) Manually rotate the shaft to ensure that there is no

rubbing or binding.

f) On belt driven units, adjust the pump or driver

sheave to maintain belt alignment. (Refer to

Section 4.5.2.2).

g) Check the alignment on direct driven units (refer

to Section 4) and reassemble the coupling

components.

h) Replace any safety guards that may have been

removed.

6.11.3 Frame 6

NEVER ATTEMPT TO CHANGE THE

CLEARANCE WHEN THE PUMP IS RUNNING.

If the coupling has limited axial adjustment capability,

the pump and driver must be uncoupled prior to

adjusting the clearance in order to permit free

movement. Before doing so, ensure that the impeller

is free to rotate. Settled slurry will make impeller

adjustment difficult. The casing may have to be

flushed to remove heavy slurry.

a) Loosen the eight (8) cartridge hold down bolts

located on the side of the cartridge [3130].

b) Move the cartridge towards the pump suction by

adjusting the screw on the adjusting assembly

that is mounted on the pedestal between adjacent

ribs until the impeller makes contact with the

suction side liner [1916.1]. It is advisable to rotate

shaft/impeller while making the adjustment as the

first sign of contact will signify zero clearance. If

the impeller can not be rotated the cartridge

should be adjusted backwards until the impeller is

just making contact. Place a dial indicator on to

the shaft end or bearing cartridge and set

indicator to zero.

c) Determine the required impeller axial running

clearance from Section 3 and add this to the

above measurement to establish the required gap

setting. Adjust the cartridge/shaft away from the

casing until the desired reading is achieved.

d) Tighten the hold down bolts on the cartridge side

flanges in accordance with tables in 6.6.