28

Flowserve US Inc.

SIHI

dry

dry

dry

dry

Standard

Standard

Standard

Standard M Series

Dry Running Vacuum Pump

Issue Date: November 21, 2016 Copyright:

FLOWSERVE SIHI Pumps Rev 1

3.6 Functional Description Purge Gas System [Pressurized & Purged Enclosure acc. NFPA496]

The purge gas system enables the application

of the SIHIdry system in explosive areas (Class

1 Division 1, 2). It consists of a purge gas

monitoring device connected to the vacuum

pump enclosure. After adequate purge gas

pressure has been attained, a switch contact

that is to be evaluated in a supply by the

Operating Company is closed. All supply

voltages, inputs and outputs to the pump must

be isolated when purge contact is open by the

Operating Company.

Penetration of an explosive mixture into the

motor compartment and electronic casing is

prevented by maintaining the inflammation-

protection gas, nitrogen, at an excess pressure

in these compartments. A differential pressure

switch is installed to monitor the pressure

difference of the discharge of the pump

chamber and the electrical casing. If the

discharge pressure becomes greater than or

equal to the electrical casing pressure the

SIHIdry system shuts down. All necessary

purge settings are preset by manufacturer and

must not be changed.

Supply Pressure, Gas Specifications:

Clean Dry Oil Free Air or Inert Gas (N2) - Class 2-4-1 acc. DIN ISO 8573-1: 2010.

Maintained between 3-8 barg (44-116 psig), regulator fitted by others.

Purge gas and separate supply for logic circuits used, then: Logic supply to be maintained between 3-8 barg

(44-116 psig), regulator fitted by others.

For more information please consult the D707 mini-Purge Manual ML546.

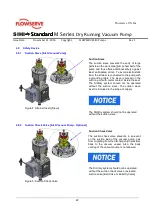

Purge Gas

Monitoring

Device

Purge Gas IN

Figure 11: Purge Gas Control Unit

Summary of Contents for SIHI dry Standard H Series

Page 82: ......