58

Flowserve US Inc.

SIHI

dry

dry

dry

dry

Standard

Standard

Standard

Standard M Series

Dry Running Vacuum Pump

Issue Date: November 21, 2016 Copyright:

FLOWSERVE SIHI Pumps Rev 1

9.6 Before Starting the SIHIdry

Vacuum Pump

Before switching on the following points need to be verified:

•

All pipelines are connected and the flanges are tight.

•

The measuring and safety devices are connected and adjusted.

•

The connection and the verification of the safety devices and equipment has to be done as

described in the respective operating instructions.

9.6.1

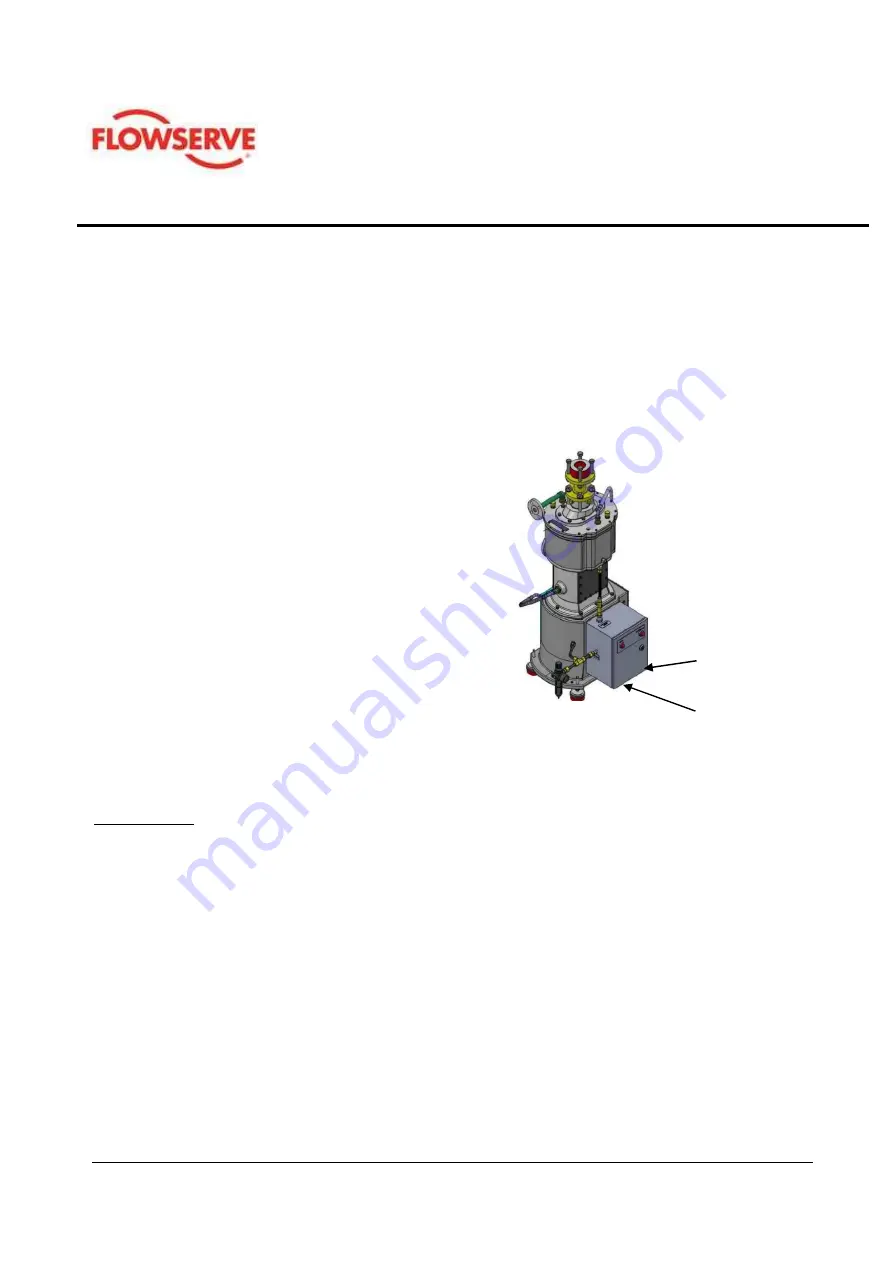

Purge Gas Control Unit [NFPA 496 – Purge Type Z/Y/X]

Switch on the purge gas supply. Check the

correct setting of the pressure reducer (45-90

PSIG) and possible leakages.

The purge gas module starts flushing the motor

compartment and the electronic unit.

Indicator [1] will switch from “red” into “green”

and indicator [2] will flash during the purge time

until is completed successfully.

This process may take several minutes

•

SIHI

dry

H250/400 approx. 5 min

•

SIHI

dry

H630/1000 approx. 10 min

and is indicated with a "green" display light to the

right [1] on the purge gas module.

After successful completion of the flushing

process, the contact [Pressure Switch] in the

purge gas module and the corresponding

component of the safety chain in the supply are

closed.

This status is indicated by the “green” display

light to the left [2] on the purge gas module.

Figure 20: Expo Purge Gas Control Unit

9.7 Initiation SIHIdry

into Operation

Commissioning

1. Note: The parameters set for reliable operation of the SIHIdry, e.g. limit values for temperature and

pressure, must not be modified without consultation with the manufacturer.

2. Inspection of the coolant - Is the filling height in accordance with the value on the data sheet?

3. If used, switch on the supply of compressed air, flushing gas and dry purging gas, check the adjustment

of the pressure reducer in the flushing gas supply line (see data sheet) and pay attention to possible

leakage.

4. Switch on the cooling water supply. Consider the required volumetric capacity of your pump (see data

sheet). Note: If the permitted coolant temperature or the pre-inlet temperature is exceeded you must

increase the flow rate of the cooling medium or reduce its temperature.

[2]

[1]

Summary of Contents for SIHI dry Standard H Series

Page 82: ......