WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 10 of 76

2.3

Lifting

EQUIPMENT CAPACITY

Make sure that any equipment used to lift the pump

or any other of its components is capable of

supporting the total weight encountered. Make sure

that all parts are properly rigged before attempting to

lift.

TRAINED PERSONNEL

A crane must be used for all pump sets in excess of

25 kg (55 lb.). Fully trained personnel must carry out

lifting, in accordance with local regulations. The

driver and pump weights are recorded on their

respective nameplates or massplates.

For weights of pump, driver, and cradle and

soleplates, see the Outline Drawing Section 8.

Parts can be damaged using the end

of the pump shaft as lifting points. Avoid lifting the

pump by nozzles or drip pockets; they are not

stressed for the load.

Whenever possible, rig spreader bars to

prevent cables from cutting into equipment, thus

avoiding any need to remove equipment to avoid

damage. To lift the complete pump or the casing off

the baseplate, place a single nylon lifting strap

around the casing at the center of gravity.

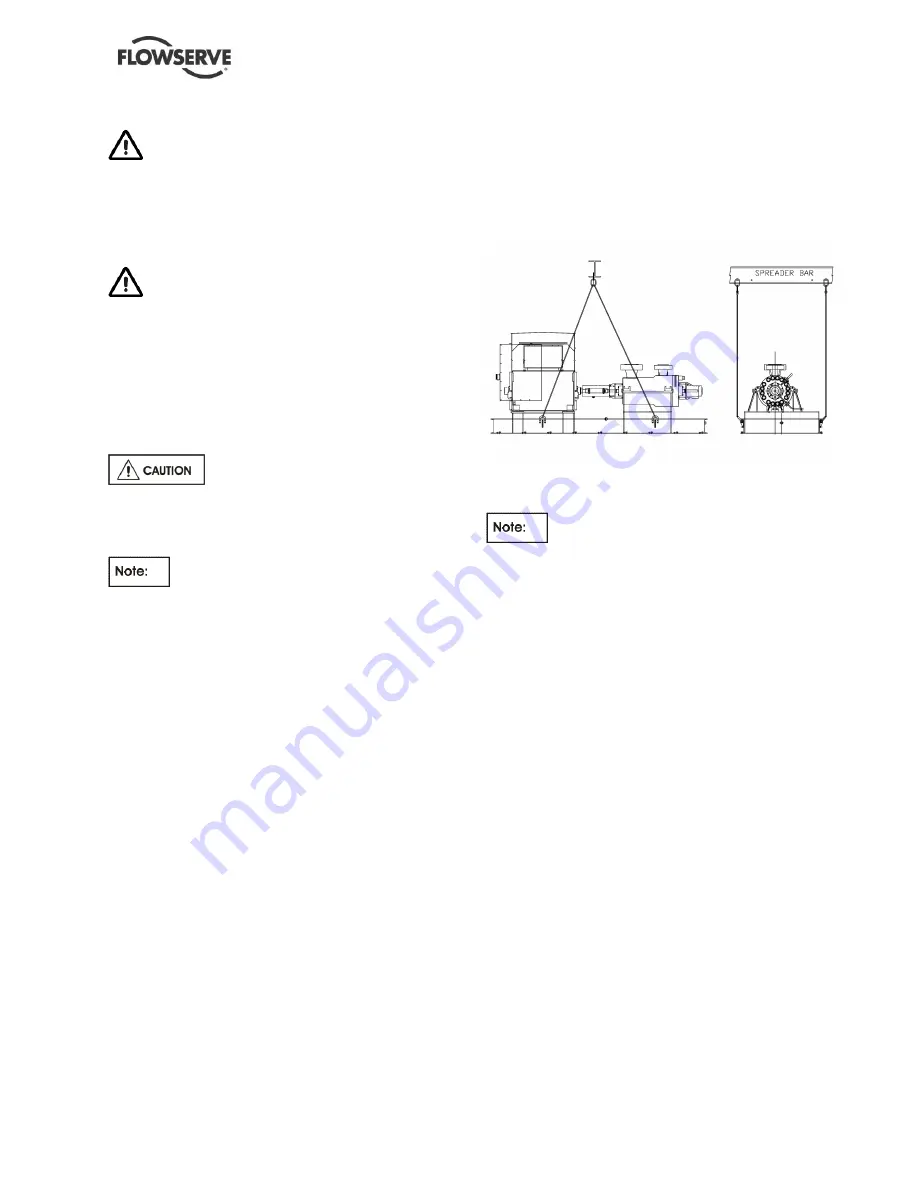

2.3.1 Baseplate-mounted pump and driver

The four cardinal points for lifting the combined

weight of baseplate and mounted pump and driver

(or just the baseplate with pump) are located

towards the ends of the baseplate. Their positions

are physically defined by pipes that act as holders

for lifting bars or lugs that afford use of clevises.

These pipes or lugs are welded to the baseplate

structure (see the Outline in 8). To set up for lifting

the baseplate, proceed according to the following

instructions.

1) Slide 75 mm (3 in.) bars which are long enough

to extend well past sides of baseplate into pipes

in baseplate or attach clevises to lifting lugs at

each end of baseplate, whichever is applicable.

2) Attach cables to 75 mm (3 in.) bars or clevises in

lugs at the four cardinal points.

3) Attach hoist to apparatus, take up slack in

cables and check to see that cables do not cut

into pump, driver, or attached equipment. If it

appears that cable will cut into an item, stop

hoist, and protect item with wood blocks, if

possible; otherwise remove the item. See

Figure 2-1

: Baseplate mounted Pump & Driver

Lifting.

4) Insure that hoist is over center of gravity of

baseplate and that cables are not cutting into

any item.

5) Hoist unit and dispose of it.

Figure 2- 1: Baseplate mounted Pump & Driver

Lifting

After the baseplate has been secured in

position, verify that pump and equipment are

undamaged and that items which had been removed

for lifting the baseplate have been reinstalled (see

section 4.6.2).

2.3.2 Soleplate-mounted barrel pump

There are two sets of four cardinal points that can be

used to lift the combined weight of barrel pump,

cradle and soleplates. Their positions are physically

defined by holes in each corner of the cradle and by

holes in each pump foot. Complete the set of

instructions below (step 1 or step 2) that is

applicable to your circumstance.

1) When using apparatus (see section 2.3) and

four cardinal points of cradle to lift combined

weight or to lift just pump and cradle:

a) Install clevis in hole at each corner of cradle

b) Attach chain (or cable) to each clevis

c) Attach hoist to apparatus and take up slack

d) Verify that cables will not cut into pump,

lagging, piping, panels, etc.

e) Establish that hoist is over center of gravity

f) Hoist unit and dispose of it.

2) When using four cardinal points of pump, to lift

combined weight, pump and cradle, or just

pump:

a) Remove lagging (if installed) exposing pump

feet

b) Install clevis in hole in each pump

c) Attach hoist to cables and take up slack