WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 21 of 76

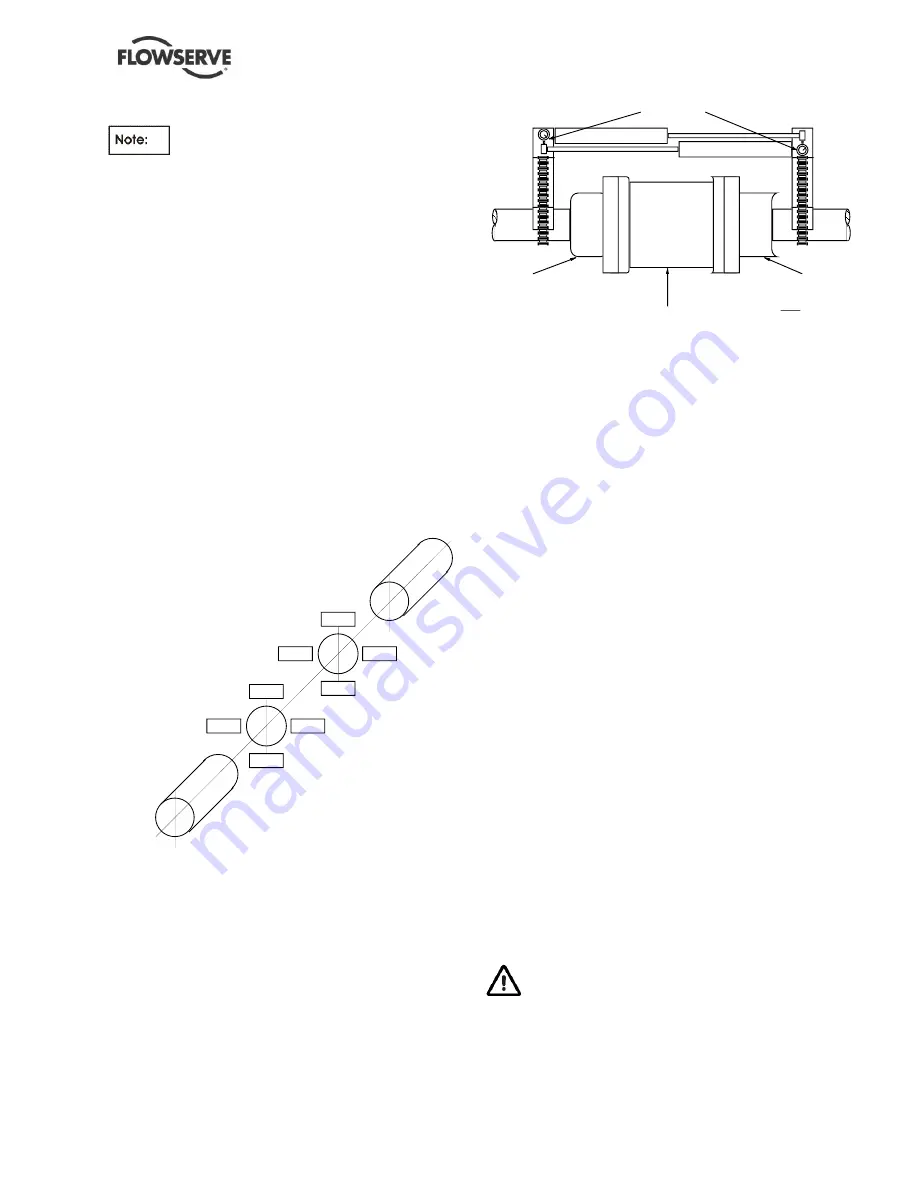

All indicator readings must be taken on the

periphery or rim of the coupling hub or shaft, and

recorded as viewed from the fixed unit (see

Figure

4-5

Alignment Orientation).

f) Attach bracket to the movable unit coupling

hub or shaft. (See

Figure 4-6

Dial Indicator

Setup For Alignment below) Take the

readings on the fixed unit coupling hub or

shaft.

g) Set the bar sag amount determined in steps

a through e above into the indicator as a

plus amount (example: an indicated 0.08mm

(-0.003 in.) would be set in as a +0.08mm

(+0.003 in.)) while in the upright (12 o'clock)

position.

h) Rotate both shafts 180° (to the 6 o'clock

position) and record indicator reading.

i) Repeat steps g and h to verify accuracy.

j) Set the bracket to the horizontal (9 o'clock)

position and set indicator to "0". Bar sag is

not applicable in the horizontal position.

FIXED UNIT

3

12

3

6

9

1

2

4

3

12

3

6

9

1

2

4

MOVABLE UNIT

Figure 4- 5 : Alignment Orientation

PUMP (OR OTHER UNIT)

HALF-COUPLING

SPACER (INSTALLED)

DRIVER (OR OTHER UNIT)

HALF-COUPLING

DIAL INDICATORS

NOTE

TO PREVENT DEFLECTION OF DIAL

INDICATORS THE BRACKETS MUST

BE RIGID IN CONSTRUCTION AND

SECURELY FIXED IN POSITION

Figure 4- 6 : Dial Indicator Setup for Alignment

k) Rotate both shafts 180° (to the 3 o'clock

position) and record indicator reading.

l) Repeat steps j and k to verify accuracy.

m) Remove bracket from movable unit coupling

hub and attach to fixed unit coupling hub.

n) Repeat steps g through I with readings

taken on movable unit.

o) Check your readings; misalignment of

connectable shafts must not exceed 0.25

mm (0.01 in.) in either the horizontal or the

vertical plane, before grouting; thus, if total

indicator reading (TIR) between 6 o'clock

and 12 o'clock points (that is, in the vertical

plane) or TIR between 3 o'clock and 9

o'clock points (that is, in the horizontal

plane) exceeds maximum allowable, you

should:

Verify that there is enough clearance

between hold down bolts and holes to

permit correction of misalignment in

horizontal plane (TIR should be

rechecked) and ensure that shimming

will permit correction in the vertical

plane; but, if these are inconclusive:

Remove every unit but pump from

baseplates (or soleplates) and repeat

steps 6 through 10 as necessary to

ensure alignment.

11) Remove all units from baseplates.

12) Grout baseplates as described under section 4.4.

Do not attempt any maintenance,

inspection, repair or cleaning in the vicinity of

rotating equipment. Such action could result in

injury to operating personnel.