WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 27 of 76

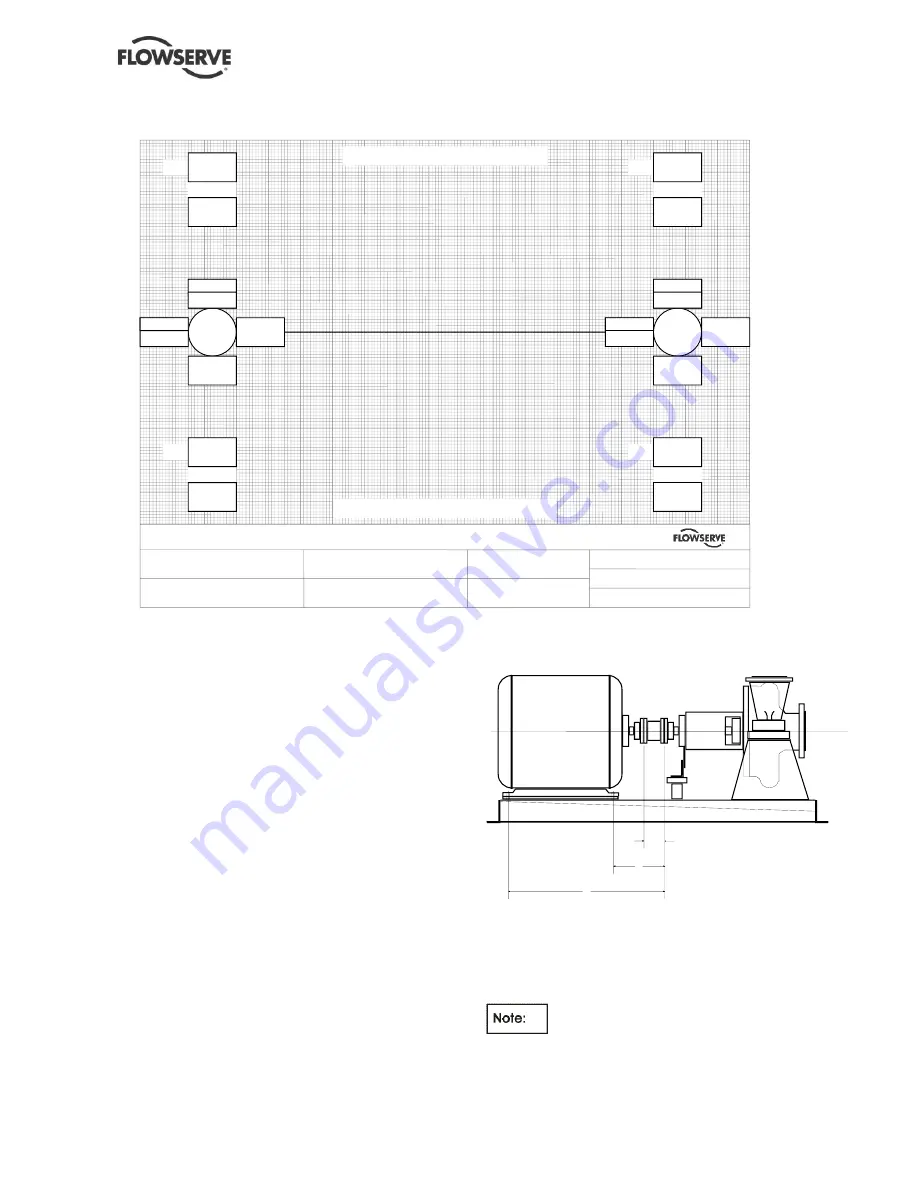

Vertical Movement Calculations

Horizontal Movement Calculations

Movable Unit Scale

Fixed Unit Scale

+50

+40

+30

+20

+10

0

-10

-20

-30

-40

-50

-60

+60

-50

-40

-30

-20

-10

0

+10

+20

+30

+40

+50

+60

-60

180

0

90

270

3

Indicator

2

4

1

Set Bar Sag

+

÷ 2 =

2 =

÷ 2 =

4 =

180

0

90

270

3

Indicator

2

4

1

Set Bar Sag

+

÷ 2 =

2 =

÷ 2 =

4 =

50 cm

20 in.

100 cm

40 in.

150 cm

60 in.

200 cm

80 in.

0

0

SHAFT ALIGNMENT CALCULATOR

Cold

Hot

Pump Shop Order

Movable Unit

Fixed Unit

Measurement 1

Measurement 2

Date

Measurement 3

Location

Customer

Figure 4- 11 : Shaft Alignment Calculator

11) Rotate both shafts 180 degrees (to the 6 o'clock

position) and record indicator reading(s).

12) Repeat steps 10 and 11 to verify accuracy.

13) Set the bracket(s) to the horizontal (9 o'clock)

position. Set indicator(s) at "0". Bar sag is not

applicable in the horizontal plane.

14) Rotate both shafts 180 degrees (to the 3 o'clock

position) and record indicator reading(s).

15) Repeat steps 13 and 14 to verify accuracy.

16) Measure the distance between dial reading

points, and between dial reading point on fixed

unit hub or shaft and each hold down bolt on

movable unit (see

Figure 4-12

Alignment

Measurement Points). Record these readings on

the graph or by other suitable means.

Movable Unit

1

2

3

Fixed Unit

Figure 4- 12 : Alignment Measurement Points

17) Follow the directions on the graph sheet or use

other suitable means to plot indicator readings.

TIR in either the vertical or horizontal

plane shall not exceed maximum allowable (see

section 10.3). Readings on opposite sides must be

opposite signs. Total angularity must not exceed

0.03 mm per 305 mm (0.001 in. per 12 inches).