WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 40 of 76

6.1.4 Lube oil system component maintenance

6.1.4.1 Replacement lube oil system component

Isolation valves permit replacement of lube oil

system components without draining the piping.

Hence to replace a control valve, pressure switch,

temperature switch, pressure indicator, heat

exchanger, lube oil filter, or lube oil pump:

1) Set pan or rags so as to catch lube oil drips.

2) Close isolation valves (see Lube Oil Console

Manufacturer's Schematic in section 10).

3) Record how wiring is connected to terminals and

disconnect wiring, if applicable.

4) Repair or replace component in accordance with

manufacturer's instructions in section 10 or your

plant data file.

5) Install new or repaired component in piping,

including connection of wiring as recorded in

step 3 above, if applicable.

6) Open isolation valves that were closed in step 2

above.

7) Adjust control setting of component, if applicable,

as instructed by manufacturer's instructions in

section 10, the lube oil system schematic

drawing, or your plant data file.

8) Comply with starting the pump (section 5.7)

requirements.

Flow glasses and temperature indicators in the

return piping can be removed without draining the

piping; follow steps 1, 3 through 5, 7, and 8

immediately above.

6.1.4.2 Repairing and adjusting lube oil system

component

See manufacturer's instructions in section 10 and

your plant's data file for information.

6.1.4.3 Baseplate mounted reservoir

6.1.4.3.1

Reservoir Removal

When necessary to remove the baseplate-mounted

reservoir:

1) Disconnect all piping from reservoir

2) Unscrew cap screws that hold reservoir to

baseplate

3) Remove reservoir from baseplate.

6.1.4.3.2

Reservoir Cleaning

Clean reservoir with petroleum base solvent such as

kerosene or naphtha, or steam clean. Any residue

from chemicals in the steam must be removed to

prevent contamination of the lube oil.

6.1.4.3.3

Reservoir Installation

To install the baseplate-mounted reservoir:

1) Verify that reservoir is clean and in satisfactory

condition.

2) Position reservoir on baseplate and secure it

with cap screws.

3) Connect all piping.

4) Fill reservoir with correct lube oil (see section

10.3).

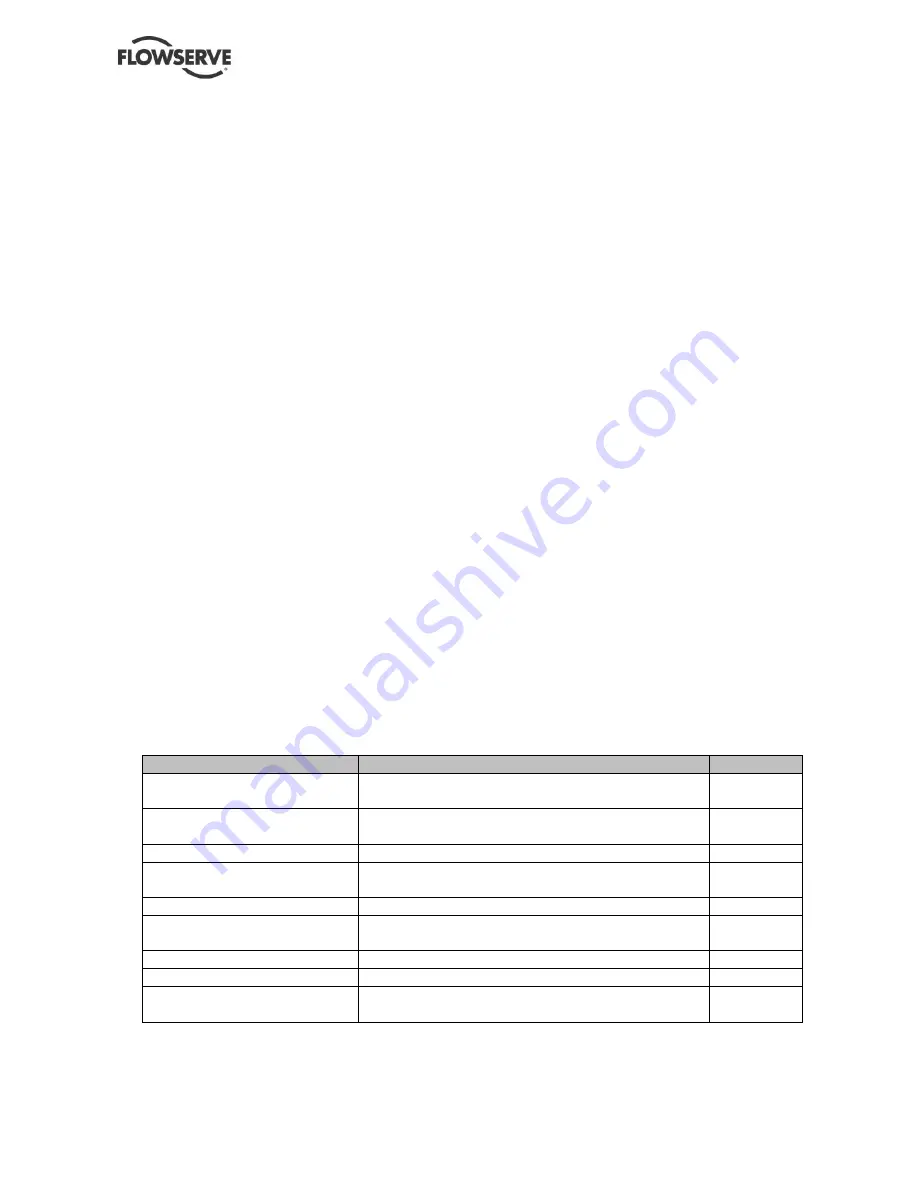

6.1.5 Preventive maintenance schedule

Refer to the below table for Maintenance schedule:

Preventive Maintenance Item

Instructions

Frequency

Suction strainer when used

Check pressure differential between the gauges.

The gauges located on each side of the strainer.

Daily

Pump Suction and Discharge

Flow Rates

Check suction and discharge pressure gauges for

proper pump operation.

Daily

Mechanical Seal

Inspect visually

Daily

Instrumentation

Check all related pressure gauges, temperature

and detectors, etc. to detect any abnormalities.

Daily

Auxiliary piping

Check for leakage around connections, etc.

Weekly

Shaft/Casing vibration

Review all vibration data for any abnormalities

and/or sudden changes in levels.

Weekly

Bolting tightness

Check all external bolting for proper tightness.

Monthly

Cleanliness

General clean-up soiled areas

Quarterly

Oil system

Refer to Lubrication System section of this

manual.

Periodically

Preventive Maintenance Schedule