WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 43 of 76

followed, the flanges can be cocked, resulting in

joint leakage and possible component damage.

5) Repeat step 4, increasing torque to

approximately 60 percent of the final torque

required (

Table 6-1

).

6) Repeat step 4, increasing torque to 100 percent

of final torque required (

Table 6-1)

.

7) Continue torquing the studs or bolts to 100

percent of final torque required (

Table 6-1

), in

the sequence printed on the studs or bolts

(

Figure 6-2

), until no further rotation of the nuts

can be achieved. This may require several re-

torquings since as one stud is torqued it will

relieve the stress on the adjacent stud until an

equilibrium has been achieved.

8) On high-pressure, high-temperature applications,

it is recommended that the flange be re-torque

to 100 percent of torque required (

Table 6-1

)

after 24 hours at operating temperature and

pressure to compensate for any relaxation that

may have occurred.

6.5.2 Torque procedure pump foot hold- down

bolts

1) Clean and inspect each stud or bolt, nut, washer,

and the facing on the flanges against which the

nuts will rotate. Look for severe galling, pitting,

etc. If any of the above mentioned items are

damaged beyond repair, replace that item.

2) Lubricate all thread contact areas and nut

facings. There are many suitable lubricants

available on the market today (i.e., Fel-Pro N-

5000, Never-Seize) that can be selected provide

the necessary low friction for installation and

adequate anti-seize properties for high

temperature applications.

3) Determine which end of the pump is fixed to its

foundation with an alignment dowel and which

end has an expansion dowel which allows

thermal expansion of the case. (This information

may be obtained from the Outline drawing in the

back of this manual or from your plant data file.)

4) Evenly torque the pump-foot hold down bolts on

the end of the pump which is fixed to the

foundation to the 100% final torque value listed

in

Table 6-1

below.

5) Tighten the other pump-foot hold down bolts

until the spring washers on the bolts are flat, and

no further.

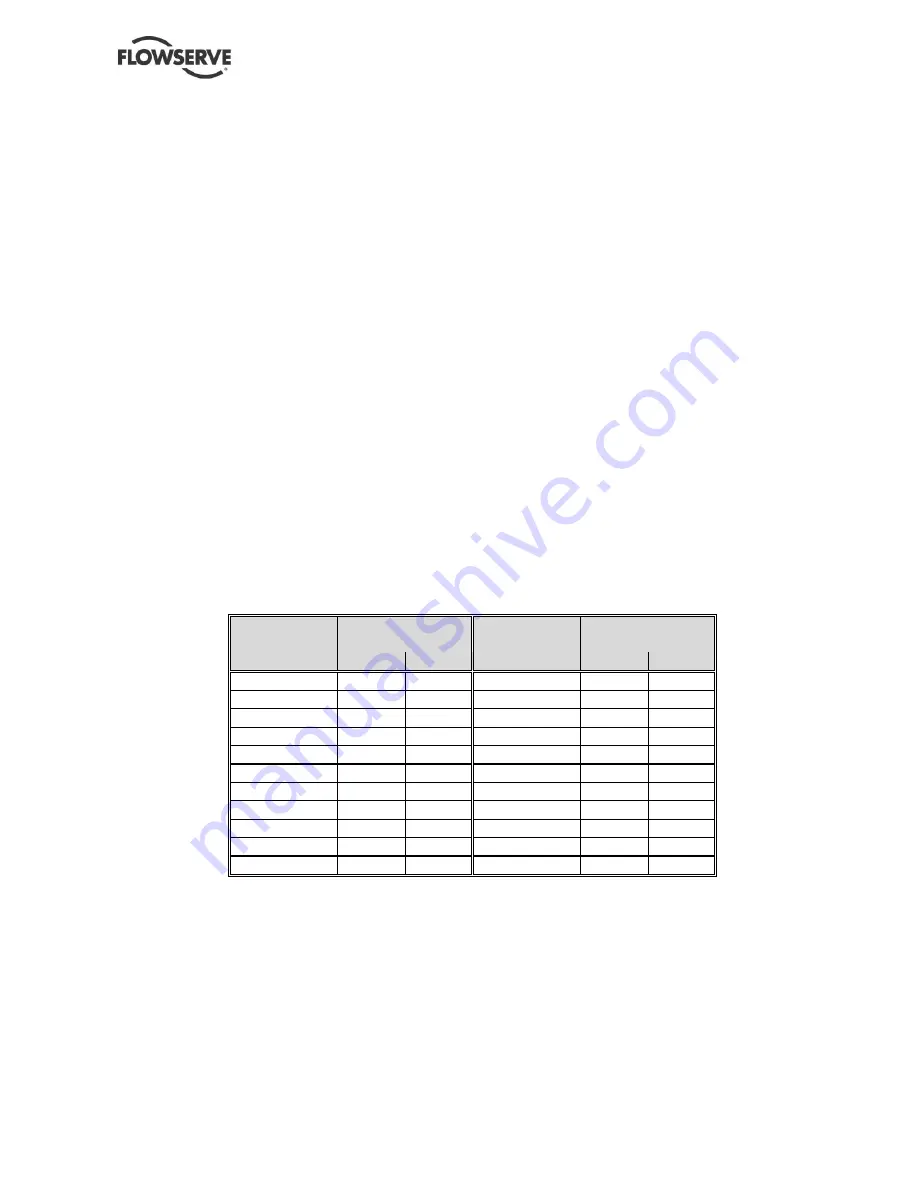

Table 6- 1 :

100% Final Torque Values by Stud/Bolt Diameter (35 kpsi stress)

Stud/Bolt

Diameter

Torque Value

Stud/Bolt

Diameter

Torque Value

(in)

(N-m)

(ft-lbs)

(in)

(N-m)

(ft-lbs)

0.500-13UNC

40

29

1.750-8UN

2,192

1,617

0.563-12UNC

58

43

1.875-8UN

2,733

2,016

0.625-11UNC

80

59

2.000-8UN

3,356

2,475

0.750-10UNC

143

106

2.250-8UN

4,873

3,594

0.875-9UNC

232

171

2.500-8UN

6,789

5,007

1.000-8UNC

349

257

2.750-8UN

9,150

6,749

1.125-8UN

518

382

3.000-8UN

12,004

8,854

1.250-8UN

735

542

3.250-8UN

15,397

11,356

1.375-8UN

1,005

741

3.500-8UN

19,375

14.290

1.500-8UN

1,334

984

3.750-8UN

23,985

17,691

1.625-8UN

1,727

1,274

4.000-8UN

29,274

21,591