WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 44 of 76

1

2

3

4

2

1

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

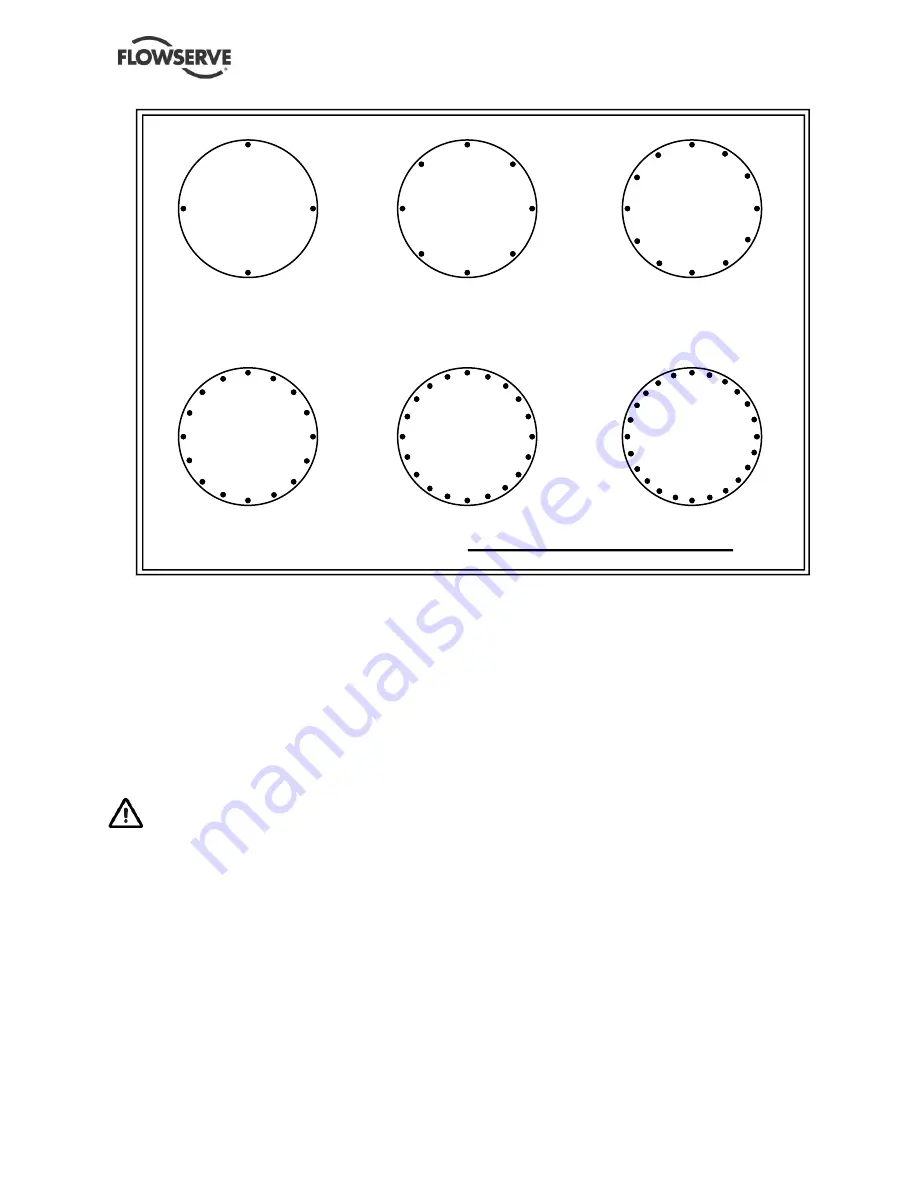

4 Bolt Pattern

8 Bolt Pattern

12 Bolt Pattern

16 Bolt Pattern

1

2

3

4

5

6

9

13

7

11

8

10

12

14

15

16

20 Bolt Pattern

1

2

3

4

13

5

17

9

15

7

19

11

14

6

18

10

16

8

20

12

24 Bolt Pattern

1

9

17

5

13

21

3

11

19

7

15

23

2

10

18

6

14

22

4

12

20

8

16

24

TORQUE PATTERN CHART

Figure 6- 2 : Torque Pattern Chart

6.6

Setting impeller clearance

Please refer to sectional drawing in section 8 or

operating specification in section 10.3 for values:

Total Element Float

Running clearances for wear rings and

bushing

6.7

Disassembly

Before disassembling pump, ensure that

the pump driver has been turned off and tagged

to prevent operation, and that the pump has

been isolated from all systems, and that all fluids

have been depressurized and drained. When

venting or draining any vessel which contains

toxic, flammable, or otherwise hazardous fluids,

ensure that the vented or drained fluid is piped

to a safe collector which will prevent release of

the fluid into the surrounding area. Do not

breathe toxic vapors. Failure to do so can result

in equipment damage, personnel injury, or death.

6.7.1 General instructions

6.7.1.1 Items and details excluded from

instructions

Since removal, installation, and tightening

procedures for common hardware such as bolts,

nuts, keys, and connectors are apparent to the

journeyman millwright, detailed steps for handling

such hardware, where it is external to the pump, are

not included in the repair tasks. Accordingly,

removal and installation procedures are not included

for piping, coolers, oil filter, and instruments (gauges,

thermometers etc.). Unless there is a handling

requirement that is peculiar to the pump, specific

lifting and related rigging instructions are not given in

this manual.

6.7.1.2 Disturbing an installation

It is unnecessary to disconnect the pump's suction

and discharge piping or to change the position of

either pump or driver except to remove it from the

baseplate. Auxiliary piping should be disconnected

only at such points as necessary for the removal of a

part of the pump. When piping is disconnected,

clean material such as plastic should be securely