WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 47 of 76

6.7.2

Coupling removal

The procedures outlined in this

subsection do not apply to keyless hydraulic fit

couplings. For installation or removal of such

couplings, refer to the applicable drawings in the

back of this manual, see section 10.

Removal of the coupling halves should be

performed by application of an even heat;

hammering is apt to distort the coupling or shaft or

otherwise cause damage.

The following work outlines include the basic steps

that must be taken to remove the half-coupling

from the unit shaft. For more detailed information,

see the coupling manufacturer’s instructions in

back of this manual, see section 10.

Complete task of removing either half-coupling

usually consists of:

1) remove the spacer that interconnects half-

couplings,

2) sliding sleeve (also O-ring where used) of hub-

and-sleeve type half-coupling back so that it is

clear of hub,

3) evenly heat hub of hub-and-sleeve type half

coupling, or solid half-coupling, with welding

torch until you are able to pull hub off shaft

with puller, then

4) removing sleeve with O-ring inside (where

applicable) and

5) removing key from shaft.

6.7.3

Removing cartridge assembly

To remove the cartridge assembly from the casing

[1100], proceed as follows:

1) Remove and tag all piping, wiring,

instruments, or other items which may

interfere with removal of the cartridge

assembly.

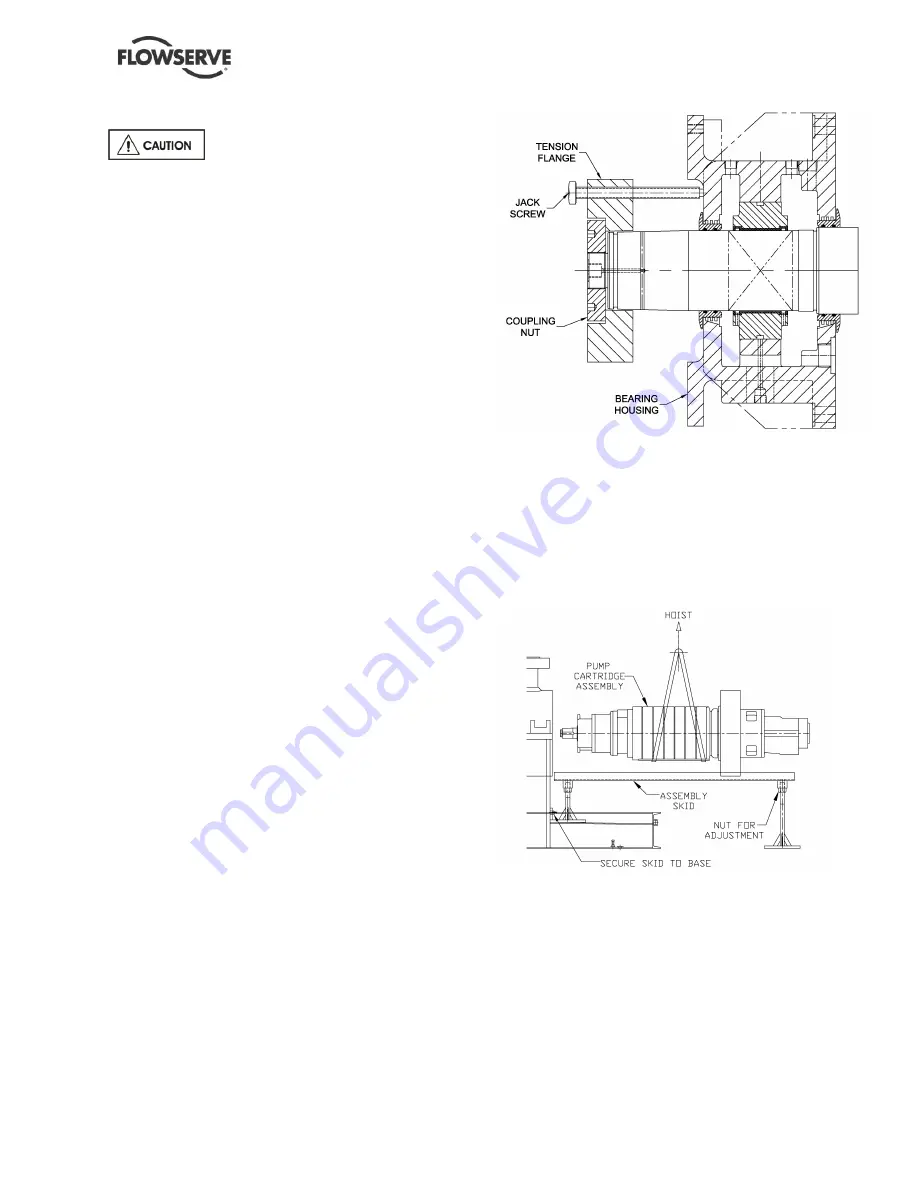

2) To secure the cartridge assembly, install the

tension flange in place of the pump half-

coupling on the shaft and secure it with the

coupling nut [7411], see

Figure 6-5

: Typical

Tension Flange Arrangement. Some cartridge

assembly may use coupling nut [7411] and

pump half coupling with the tension flange,

then install the tension flange between the

pump half coupling and bearing housing.

Figure 6- 5 :

Typical

Tension Flange

Arrangement

3) Remove either the suction end plate cap

screws [6570.3] or O-ring retainer cap screw

[6570.3] depend on the pump.

4) Tighten the jack screws in the tension flange

against the bearing housing until snug.

Figure 6- 6 : Typical Assembly Skid

5) Secure assembly skid (see

Figure 6-6

) or

equivalent device to end of baseplate. To

avoid subjecting cartridge assembly to binding

or twisting stresses or having it roll off of the

track, ensure:

a) Assembly skid is aligned and leveled with

bore of casing [1100]

b) Flange of assembly skid presses solidly

against the baseplate.

c) Feet press against a solid surface across

their entire area