WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 71 of 76

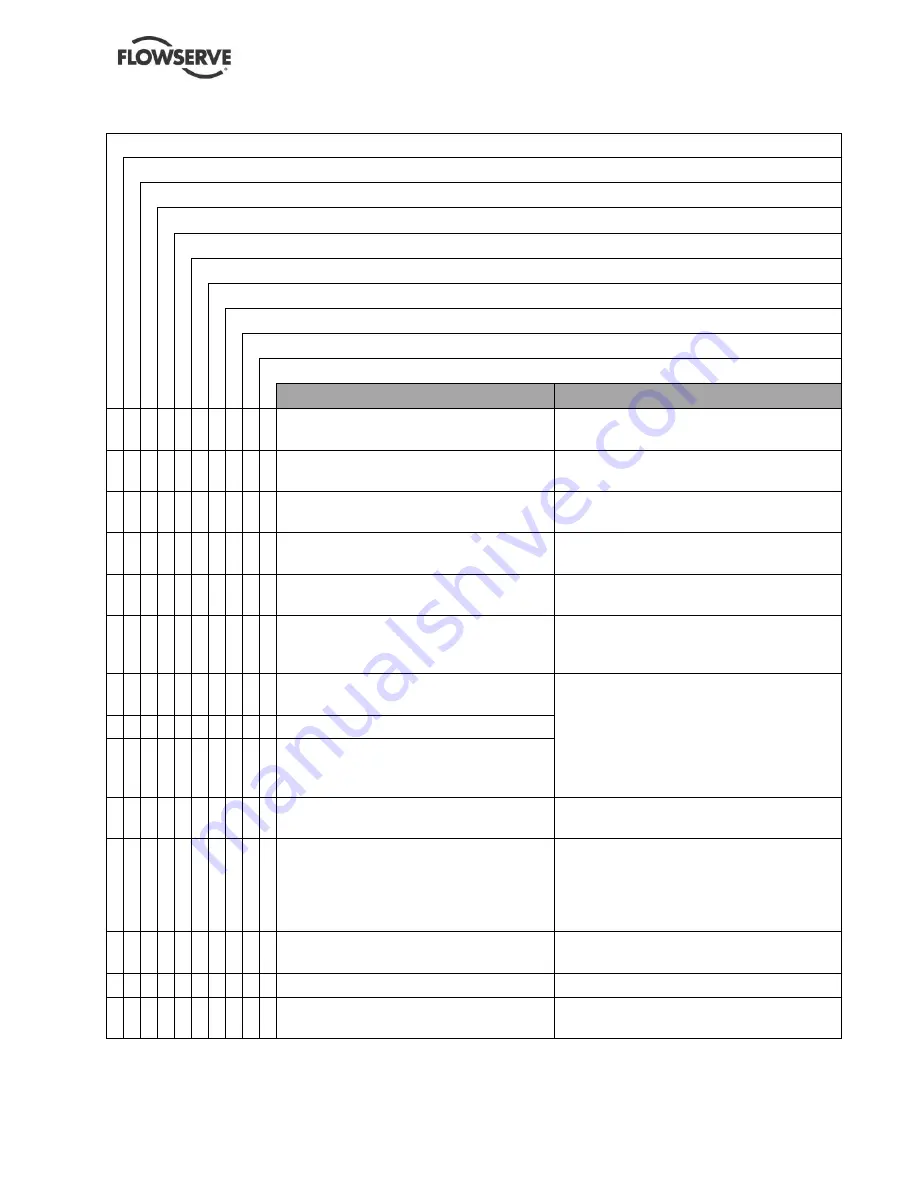

FAULT SYMPTOM

Pu m p o v e rh e a ts a n d s e i z e s

B e a ri n g s h a v e s h o rt l i f e

Pu m p v i b ra t e s o r i s n o i s y

M e c h a n i c a l s e a l h a s s h o rt l i f e

M e c h a n i c a l s e a l l e a k s e x c e s s i v e l y

Pu m p r e q u i re s e x c e s s i v e p o w e r

Pu m p l o s e s p ri m e a ft e r s ta rt i n g

I n s u f f i c i e n t p r e s s u r e d e v e l o p e d

I n s u f f i c i e n t c a pa c i t y d e l i v e r e d

Pu m p d o e s n o t d e l i v e r l i q u i d

PROBABLE CAUSES

POSSIBLE REMEDIES

Impeller damaged or eroded.

Replace or CONSULT FLOWSERVE for

improved material selection.

Leakage under sleeve due to joint

failure.

Replace joint and check for damage.

Shaft sleeve worn or scored or running

off center.

Check and renew defective parts.

Mechanical seal improperly installed.

Check alignment of faces or damaged

parts and assembly method used.

Incorrect type of mechanical seal for

operating conditions.

CONSULT FLOWSERVE.

Shaft running off center because of worn

bearings or misalignment.

Check misalignment and correct if

necessary. If alignment satisfactory

check bearings for excessive wear.

Impeller out of balance resulting in

vibration.

Check and CONSULT FLOWSERVE.

Abrasive solids in liquid pumped.

Internal misalignment of parts

preventing seal ring and seat from

mating properly.

Mechanical seal was run dry.

Check mechanical seal condition and

source of dry running and repair.

Internal misalignment due to improper

repairs causing impeller to rub.

Check method of assembly, possible

damage or state of cleanliness during

assembly.

Remedy or CONSULT FLOWSERVE, if

necessary.

Excessive thrust caused by a

mechanical failure inside the pump.

Check wear condition of impeller, its

clearances and liquid passages.

Excessive grease in ball bearings.

Check method of regreasing.

Lack of lubrication for bearings.

Check hours run since last change of

lubricant, the schedule and its basis.