WIK USER INSTRUCTIONS ENGLISH BO2662 5/09

Page 74 of 76

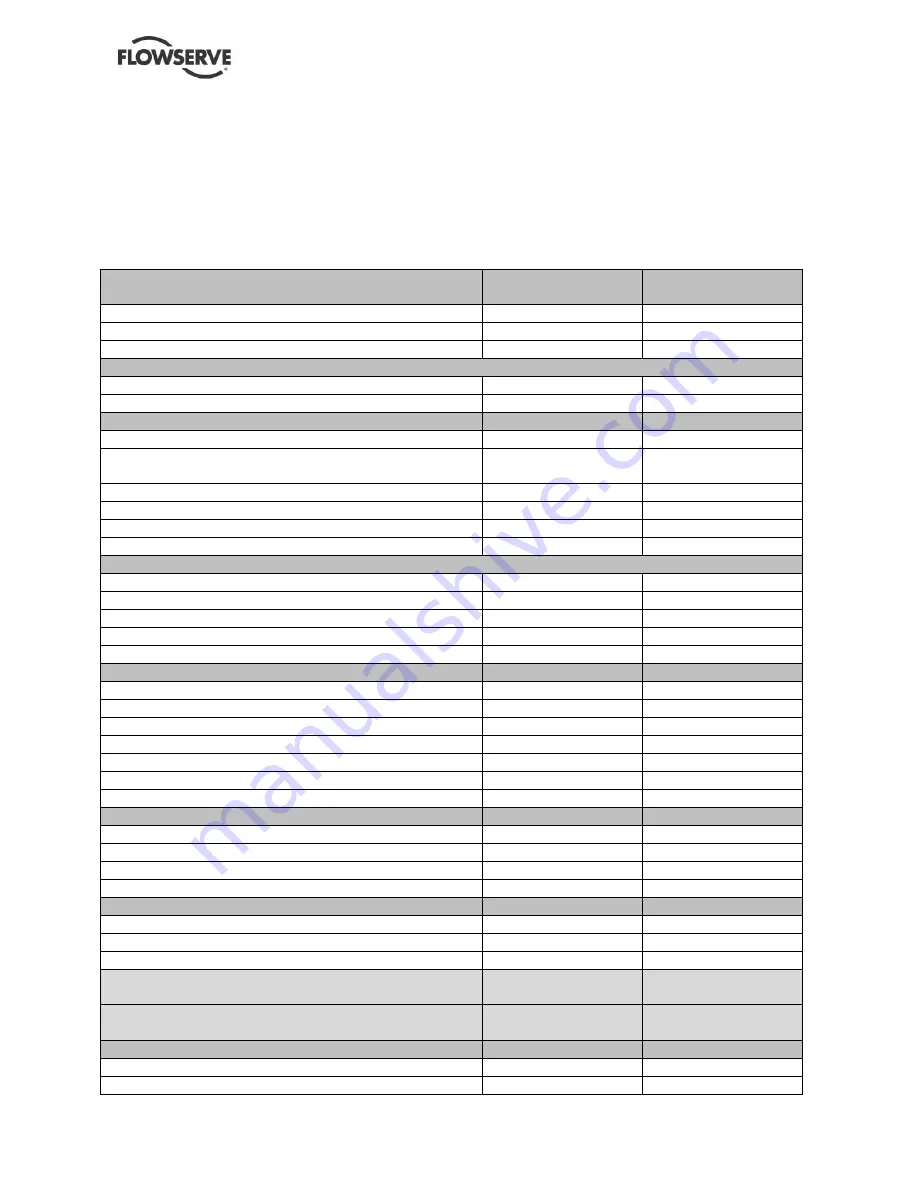

10.3

Operating specification

PUMP SERIAL NUMBER BXXXXX-01

Pump design clearances are listed below. Use these clearances for restoration when clearances have

increased approximately 50% as evidenced by a decrease in performance or excessive vibration

Metric

English

Baseplate Installation

mm, °C

Inch, °F

Grout space above foundation (minimum)

25.4

1.0

Leveling Gradient

.03 per 305

.001 per 12

Centerline misalignment of multiple baseplates

.25

.010

Shaft Coupling

Straight Coupling removal/installation heat

177

350

Maximum TIR in all planes of connectable shafts

.05

.002

Dimensions

Min.

Max.

Min.

Max.

Rotor shroud p

osition (Dimension “X”)

.00

0

Rotor axial movement (thrust bearings removed)

(minimum)

9.53

.375

Thrust bearing axial clearance

.00

.00

0

0

Deflector ring axial position clearance

1.52

.060

Impeller wear surface removal, maximum for truing

1.52

.060

Rotor centering at seal bores, maximum TIR

.03

.001

Runout, maximum TIR

Bare shaft in V-blocks

.03

.001

Rotor

.05

.002

Wear rings and bushings

.05

.002

Thrust collar face

.013

.0005

Thrust collar outer diameter

.140

.0055

Running Clearances, diametrical

Min.

Max.

Min.

Max.

Journal bearing to shaft. see Table 10-1 this section

Oil baffle.

see Table 10-1 this section

Suction Impeller

drive end

.25

.00

.010

.000

Suction Impeller

non drive end

.00

.00

0

0

Radial Impeller

drive end

.00

.00

0

0

Radial Impeller

non drive end

.00

.00

0

0

Pressure reducing sleeve

.00

.00

0

0

Part-to-Shaft fits

Min.

Max.

Min.

Max.

Suction Impeller, drive end

interference fit

.000

.000

0

0

Radial Impeller, drive end

interference fit

.000

.000

0

0

Pressure reducing sleeve

interference fit

.000

.000

0

0

Thrust collar

interference fit

.000

.000

0

0

Part-to-Part fits

mm, °C

Inch, °F

Suction spacer, intermediate cover, discharge cover

interference fit

0

0

0

0

Destaging spacer

.03

0

‘Cover-to-case gap shall be parallel all around within

.25

.002

Cover-to-Case Nut torque procedure

See procedure in this section 6.5.1

Pump Foot Hold down Bolt torque procedure

See procedure in this section 6.5.2

Part removal heat, maximum

°C

°F

Impeller

316

600

Pressure Reducing Sleeve

316

600