Installation

Inputs and Outputs

39

5

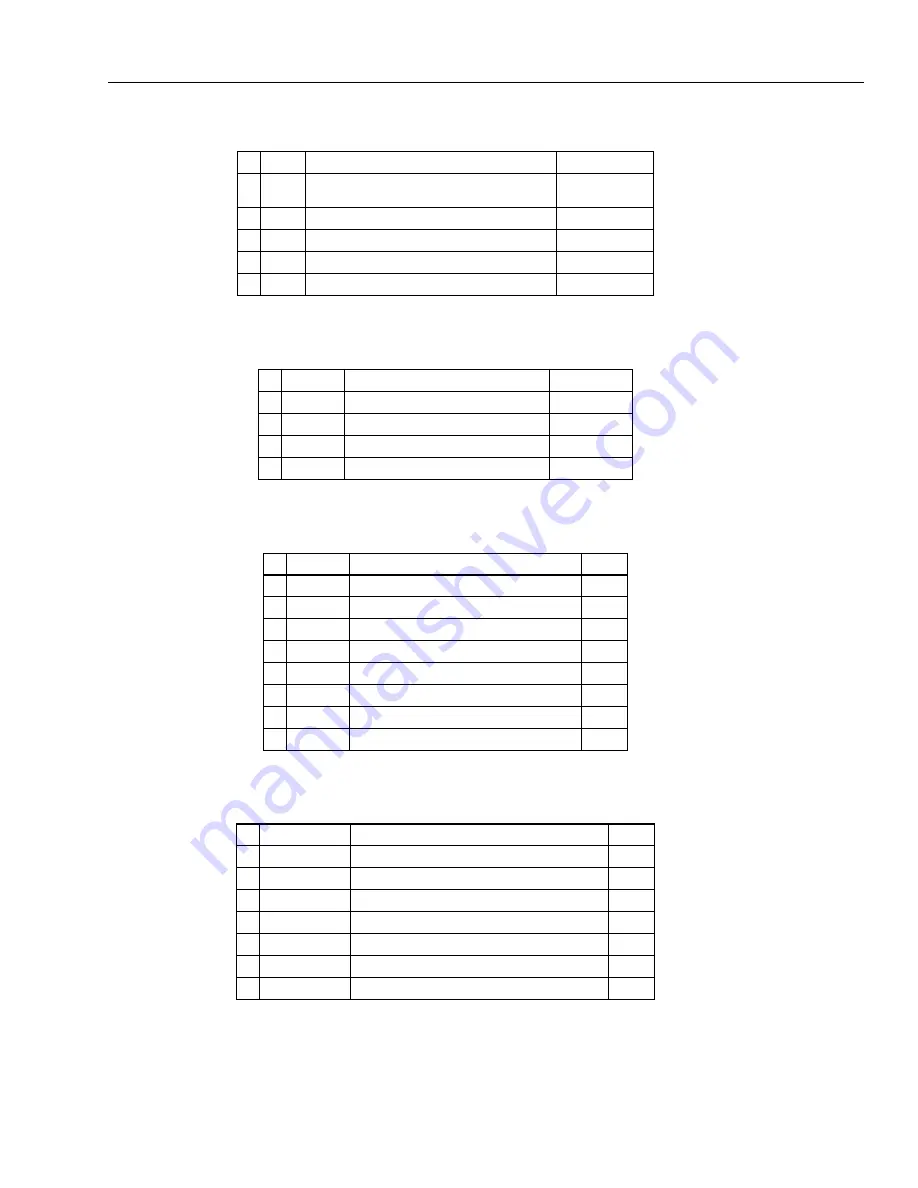

Table 5-4: Current Outputs, 4 pins

Description

Color

1

IGND

common ground connection for all current outputs,

electrically isolated to the GND ground

brown, pink, gray

2

OUT1

current output 1

yellow

3

OUT2

current output 2

green

4

OUT3

current output 3

white

shield

black

Table 5-5: Power Supply, 3 pins

Description

Color

1

GND

power ground

brown

2

not connected

3

+ 24 VDC

input for + 24 VDC power supply voltage

white

shield

black

Table 5-6: RS485 Interface, 7 pins

Description

Color

1

GND

Ground, (connected to power ground)

gray

2

T+

RS485 transmit

brown

3

T-

RS485 transmit

white

4

R+

RS485 receive

green

5

R-

RS485 receive

yellow

6

n.c.

7

+ 12 VDC

regulated voltage for the RS232/485 converter

pink

shield

Table 5-7: Alarm and Trigger, 6 pins

Description

Color

1

Relay contact

Potential free relay contact, capacity max. 30 V, 1 A

brown

2

Relay contact

Potential free relay contact, capacity max. 30 V, 1 A

white

3

T

Trigger input: + 5 to + 24 VDC

green

4

Trigger -

Trigger input GND

yellow

5

Functional input

max. + 5 VDC

pink

6

Functional input

GND

gray

shield

black