Maintenance and Specifications

Options and Accessories

11

11-11

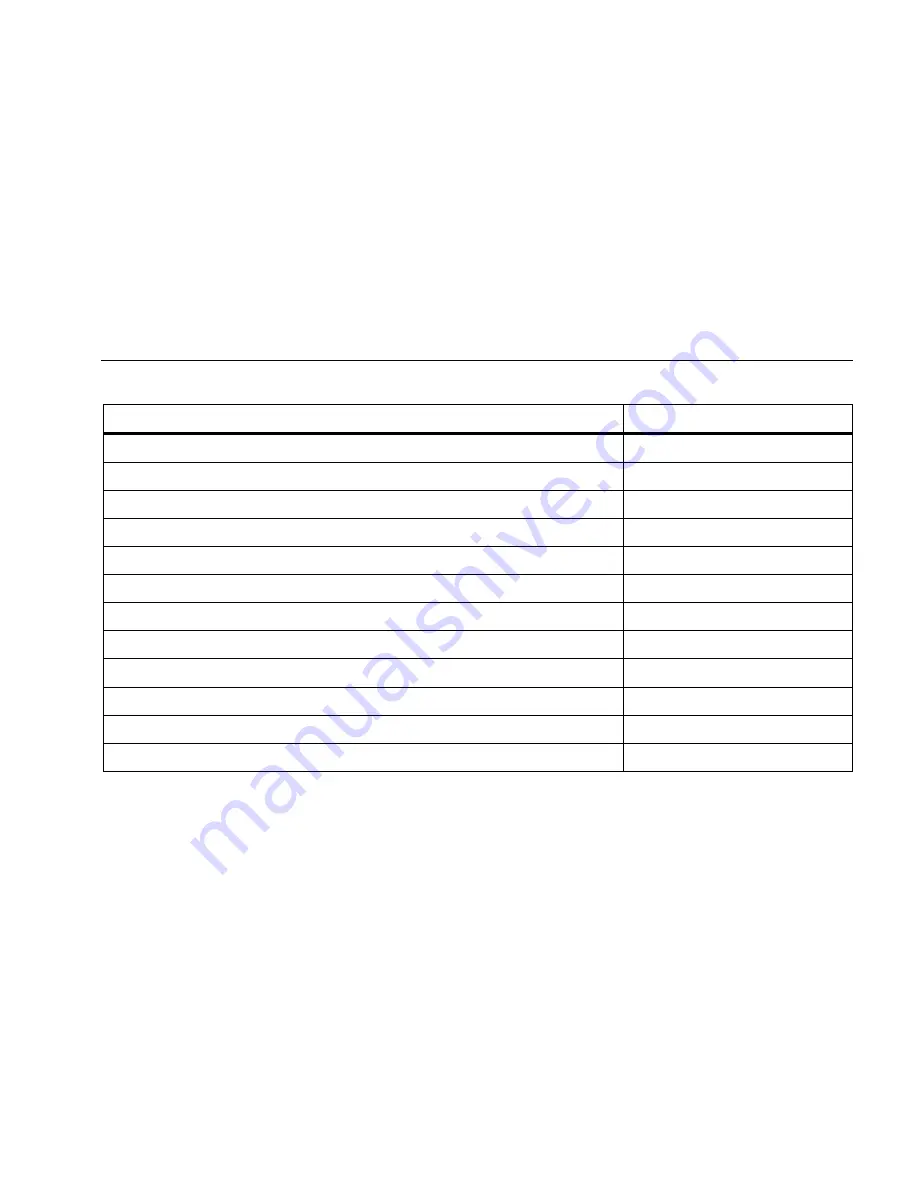

Table 11-3. Accessories

Accessory

Fluke Networks Model Number

FiberInspector

Video Probe, 250X and 400X magnifications

OFTM-5352

DTX Smart Remote with multimode module and interchangeable SC adapter

OFSR-MMREM

DTX Smart Remote module, singlemode with interchangeable SC adapter

OFSR-SFM2

DTX Smart Remote module, multimode with interchangeable SC adapter

OFSR-MFM2

32 MB Secure Digital memory card

DTX-SMC32

64 MB Secure Digital memory card

DTX-SMC64

32 MB MultiMedia memory card

DSP-MMC32

Carrying case for up to 8 memory cards

MMC CASE

Memory card reader with USB interface

DSP-MCR-U

Launch fiber, multimode, 62.5

µ

m, SC/SC, 100 m (gray zipper)

NFK1-LAUNCH

Launch fiber, multimode, 50

µ

m, SC/SC, 100 m (aqua zipper)

NFK2-LAUNCH

Launch fiber, singlemode, 9

µ

m, SC/SC, 130 m (yellow zipper)

NFK3-LAUNCH

-continued-

Summary of Contents for OF-500 OptiFiber

Page 12: ...OF 500 OptiFiber Technical Reference Handbook x ...

Page 18: ...OF 500 OptiFiber Technical Reference Handbook xvi ...

Page 27: ...Getting Acquainted Powering the Tester 1 1 9 ajt20f eps Figure 1 1 Battery Pack Features ...

Page 29: ...Getting Acquainted Verifying Operation 1 1 11 ajt56f eps Figure 1 2 Removing the Module ...

Page 46: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook 1 28 ...

Page 136: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook 4 6 ...

Page 192: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook 6 48 ...

Page 254: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook 11 36 ...

Page 256: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook ...

Page 272: ...B 14 OF 500 OptiFiber Certifying OTDR Technical Reference Handbook ...

Page 274: ...OF 500 OptiFiber Certifying OTDR Technical Reference Handbook C 2 ...

Page 282: ...OF 500 OptiFiber Technical Reference Handbook 8 ...