PG9602™ OPERATION AND MAINTENANCE MANUAL

© 2011 Fluke Calibration

Page

164

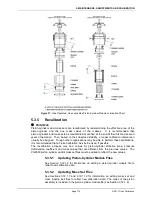

Place the piston-cylinder module upside down

on a clean stable surface (piston cap (2)

down).

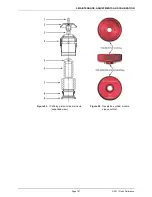

Using the 10 kPa/kg side of the sleeve nut tool

(see Figure 24), remove the sleeve nut (9).

The sleeve nut tool is a spanner that fits into

the two holes on the sleeve nut.

Step 1 and 2

Remove the O-ring assembly (8). Then,

being sure to support the cylinder (7) so it

doesn’t fall out, turn the remaining assembly

over so that the piston cap (2) is up.

Step 3

While firmly holding down the cap (2), use a 5

mm Allen tool (supplied with PG9000

accessories), to loosen the socket head cap

retaining screw (1). The cap retaining screw

will not fully disengage from the piston cap

due to the adjustment mass (3). Gently

remove the cap and screw from the

assembly.

Step 4

Summary of Contents for PG9000 Series

Page 10: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page X Notes...

Page 128: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 118 Notes...

Page 164: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 154 Notes...

Page 188: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 178 Notes...

Page 192: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 182 Notes...