Page 63

© 2011 Fluke Calibration

Shut vacuum reference shutoff valve, open vacuum vent valve. Wait for

pressure under bell jar to return to ambient. Remove bell jar. This step is not

necessary is using AMH automated mass handler and mass loading resolution

of 0.1 kg.

Repeat Steps

through for each desired differential pressure point.

See

Setting Zero Differential Pressure

Figure 19 for a schematic of the Differential Mode Controller and its valves.

Zero differential pressure can be set by PG9000 or simply by setting the

Differential Mode Controller TEST BYPASS valve to the OPEN position which

connects the HIGH and LOW TEST ports together. The TEST BYPASS valve

OPEN position is a “true” zero. The zero differential pressure value set by

PG9000 has the same uncertainty as any other differential pressure point (see

Section 1.2.4). Comparing the DUT reading at zero set by TEST BYPASS in the

OPEN position and at zero set by PG9000 in differential mode like any other

differential pressure, can help quantify the quality of the current RPM

offset value. If the difference between the two zero readings is excessive, the

RPM offset value should be redetermined (see Section 3.10.4.1, Selecting

Differential Mode, Setting Static Pressure, Finding RPM Offset (

<1run>

)).

Also, consider correcting all the DUT readings by the difference in the zero

reading found in the two different conditions to correct for the defect in the

RPM offset.

To view the current RPM offset and the static pressure value at which the offset

was recorded, press

[MODE]

and select

<4dif>

,

<2view>

. This display is:

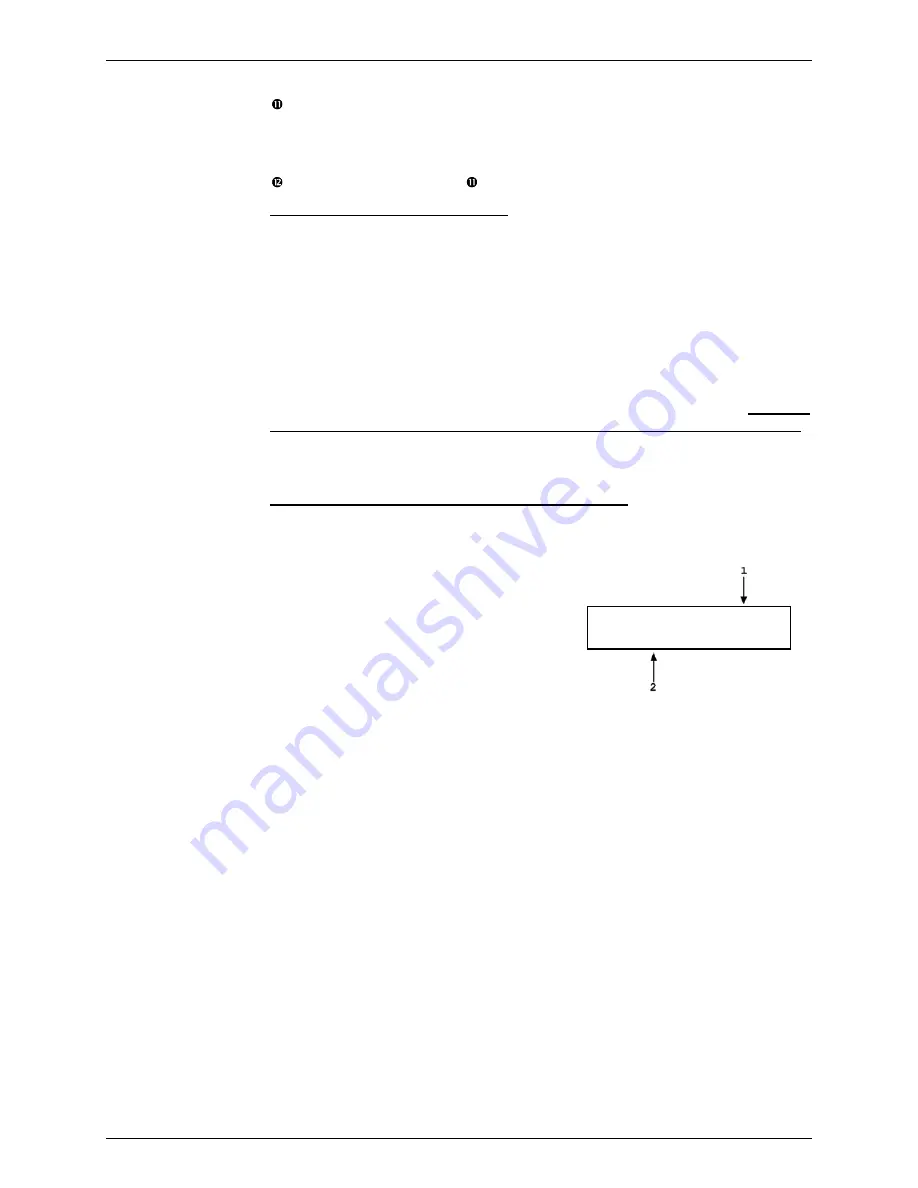

Viewing Static Pressure and RPM Offset (<2view>)

1.

RPM offset value that is currently active.

2.

PG9000 pressure at which RPM offset was

recorded.

Offset: -6.33 Pa

@99.8755 kPa a

Press

[ESC]

to return to the

<Differential mode:>

menu.

Press

[ENT]

to return to the previous run screen.

3.10.5 [SYSTEM]

PURPOSE

To access the two SYSTEM run screens which display current values of PG9000 piston

behavior, piston-cylinder temperature and vacuum reference measurements.

OPERATION

To access the SYSTEM run screens, press

[SYSTEM]

. There are three SYSTEM run screens.

Pressing

[SYSTEM]

or

[

±

]

when in a SYSTEM screen cycles through the SYSTEM screens.

See the following sections 3.10.5.1 through 3.10.5.3 for detailed information on the contents

of the SYSTEM run screens.

Note

The SYSTEM screens are run screens. This means that other functions

can be accessed from the SYSTEM screens and the active SYSTEM screen

will be returned to when leaving functions. The MAIN screen and

AMBIENT screen are also run screens (see Section 3.9).

Summary of Contents for PG9000 Series

Page 10: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page X Notes...

Page 128: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 118 Notes...

Page 164: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 154 Notes...

Page 188: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 178 Notes...

Page 192: ...PG9602 OPERATION AND MAINTENANCE MANUAL 2011 Fluke Calibration Page 182 Notes...