Theory of Operation

Transducer Module

2

2-7

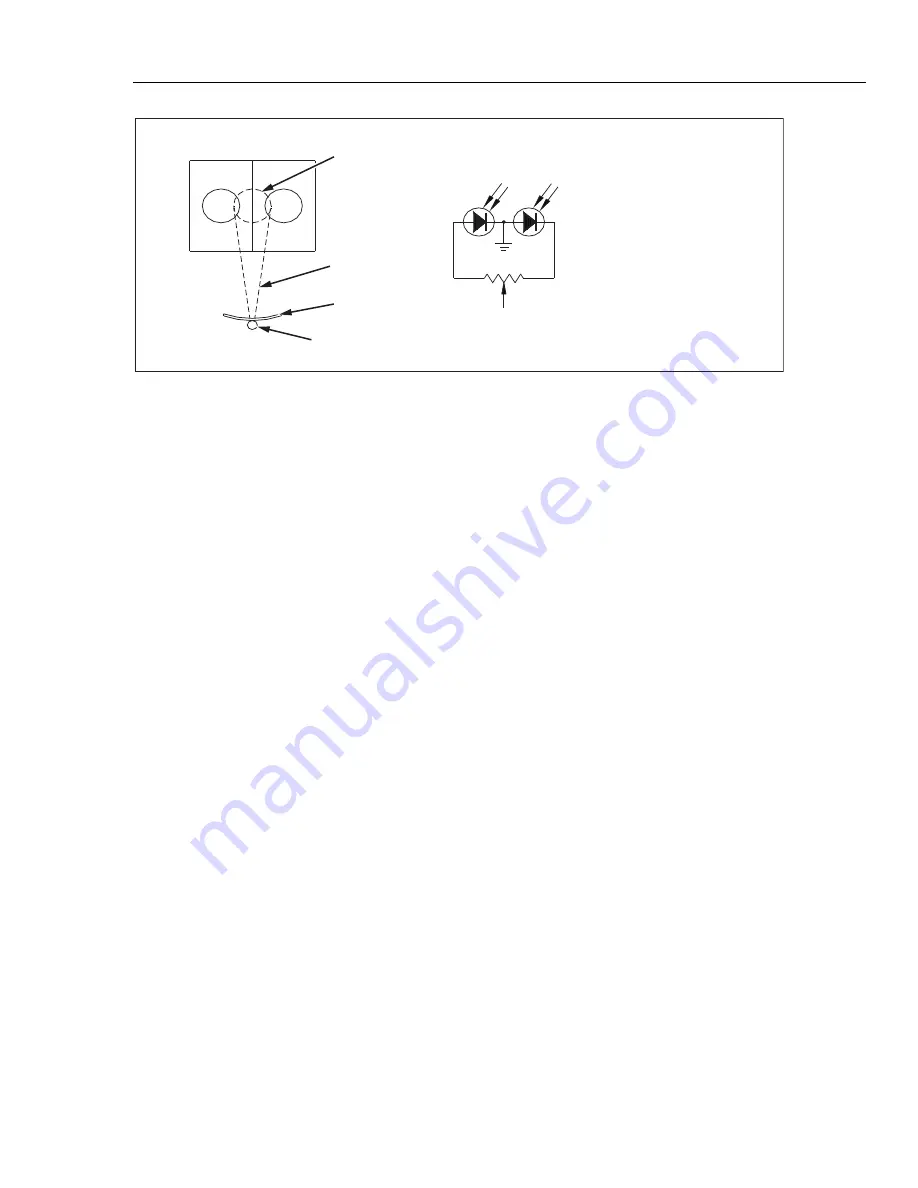

PHOTOCELLS

SHIFTING SPOT OF

LIGHT, SHOWN AT

NULL POSITION

BETWEEN PHOTOCELLS

PHOTOCELLS GENERATE VOLTAGE

ACCORDING TO ILLUMINATION

POTENTIOMETER FOR ZERO-ADJUST

CALIBRATION OF THE QBT GAGE

ERROR SIGNAL TO CONTROL AMPLIFIER IS

ZERO WHEN PHOTOCELLS ARE EQUALLY

ILLUMINATED

BEAM OF LIGHT

REFLECTED FROM

ROTATING MIRROR

MIRROR

ROTATING AXIS

LEFTHAND

RIGHTHAND

glc06.eps

Figure 2-5. Photocell/Light Spot

Sensor Board

A temperature sensor, the quartz Bourdon tube pressure sensor and vacuum sensor are

monitored by the Sensor Board. The Sensor board is also used to control and maintain the

sensor housing at 50 °C.

Linearization Term

As described in the previous section, the relationship between the pressure being

measured and the current required to keep the quartz Bourdon tube in its zero position is

the main principle behind the operation of the PPI’s sensing element.

Ideally this pressure-current relationship would be a linear equation of the form

1

KP

l

=

,

where I is current, k is a constant of proportionality, and P is pressure. However, due to

certain mechanical characteristics of the helical tube and its supporting structure, this

pressure-current relationship is slightly nonlinear. The nonlinear portion of this

pressure-current relationship closely follows the form of a second order polynomial, or

1

2

1

c

bP

aP

+

+

=

where again P is pressure and a, b, and c are coefficients generated during the calibration

procedure as discussed below.

When the user performs a three-point calibration, the PPI’s software creates the three

coefficients based on the user’s zero, mid-point, and full-scale adjustments. From then on,

the nonlinear term given above is subtracted from the total pressure-current curve to

achieve the desired linear pressure-current relationship.

On the 7050i and 7050LP, multiple quartz sensor ranges are used in order to provide the

percent of reading specification. In these instruments, a total of three points per range

with one point shared between two ranges is required. Therefore, for the 7050i, a 5 point

calibration is performed and for the 7250LP, a 9 point calibration is performed to fully

characterize the RUSKA quartz sensors.

Auxiliary Sensors

Auxiliary sensors are sensors such as the oven temperature sensor. These are reference

sensors aligned at the factory and are utilized by the firmware.

Summary of Contents for RUSKA 7050

Page 3: ...7050 Change Language Hold key for 5 seconds mode enter...

Page 4: ......

Page 10: ...RUSKA 7050 7050i 7050LP Users Manual vi...

Page 12: ...RUSKA 7050 7050i 7050LP Users Manual viii 7 1 Packing the PPI 7 3...

Page 18: ...RUSKA 7050 7050i 7050LP Users Manual 1 6...

Page 32: ...RUSKA 7050 7050i 7050LP Users Manual 3 4...

Page 60: ...RUSKA 7050 7050i 7050LP Users Manual 5 14...