Jan 31st, 2005

- 90 -

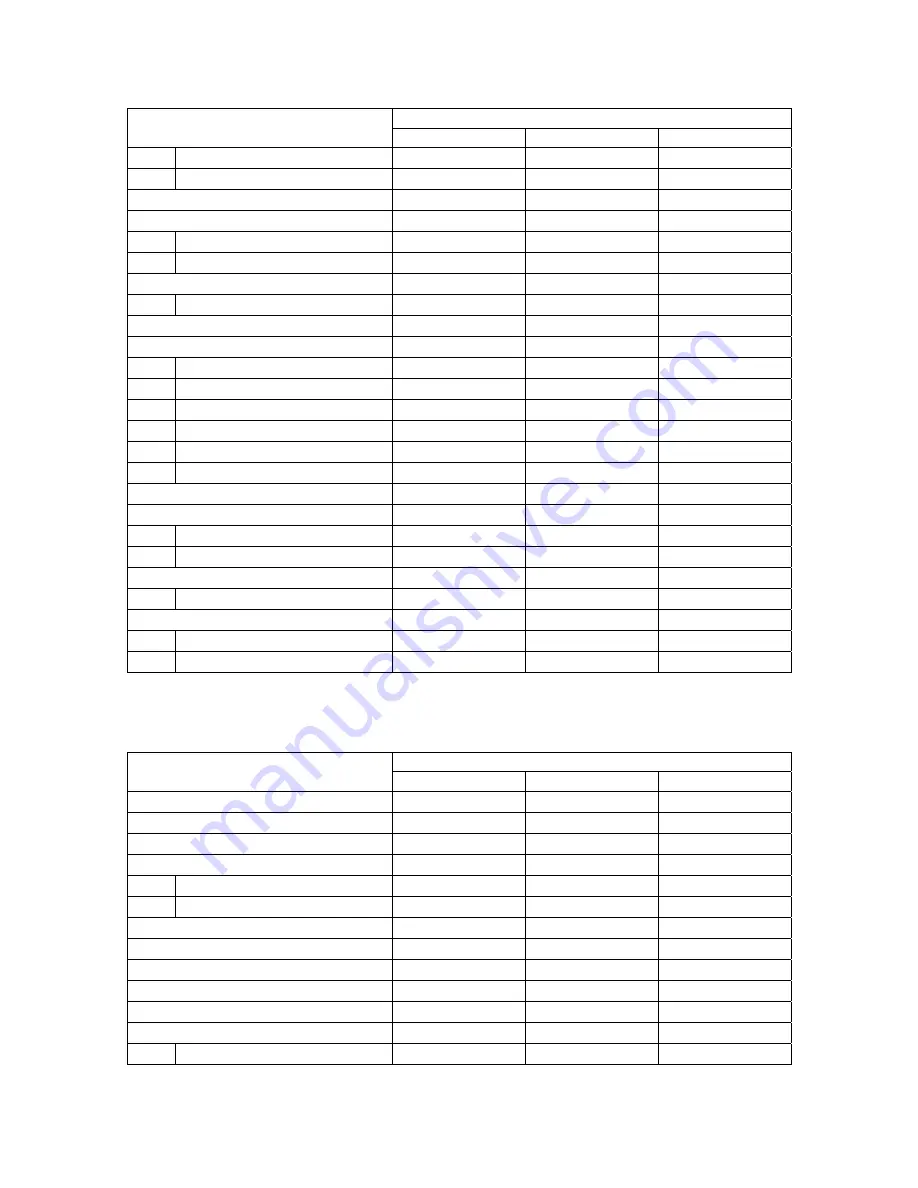

Material Emissivity

1.0µm

1.6µm

8-14µm

Oxidized

0.5-0.9

0.4-0.9

0.2-0.6

Unoxidized

0.25-0.35

0.1-0.35

0.1

Monel (Ni-Cu)

0.3

0.2-0.6

0.1-0.14

Nickel

Oxidized

0.8-0.9

0.4-0.7

0.2-0.5

Electrolytic

0.2-0.4

0.1-0.3

n.r.

Platinum

Black

n.r.

0.95

0.9

Silver

n.r. 0.02 n.r.

Steel

Cold-Rolled

0.8-0.9

0.8-0.9

0.7-0.9

Ground

Sheet

n.r.

n.r.

0.4-0.6

Polished

Sheet

0.35

0.25

0.1

Molten

0.35

0.25-0.4

n.r.

Oxidized

0.8-0.9

0.8-0.9

0.7-0.9

Stainless

0.35

0.2-0.9

0.1-0.8

Tin (Unoxidized)

0.25

0.1-0.3

n.r.

Titanium

Polished

0.5-0.75

0.3-0.5

n.r.

Oxidized

n.r.

0.6-0.8

0.5-0.6

Tungsten n.r.

0.1-0.6

n.r.

Polished

0.35-0.4

0.1-0.3

n.r.

Zinc

Oxidized

0.6

0.15

0.1

Polished

0.5

0.05

n.r.

Table 2. Emissivity Values for Non-Metals

Material Emissivity

1.0µm

1.6µm

8-14µm

Asbestos 0.9

0.9

0.95

Asphalt n.r.

0.95

0.95

Basalt n.r.

0.7

0.7

Carbon

Unoxidized

0.8-0.95

0.8-0.9

0.8-0.9

Graphite

0.8-0.9

0.7-0.9

0.7-0.8

Carborundum n.r.

0.9

0.9

Ceramic 0.4

0.85-0.95

0.95

Clay n.r.

0.85-0.95

0.95

Concrete 0.65

0.9

0.95

Cloth n.r.

0.95

0.95

Glass

Plate

n.r.

0.98

0.85

Summary of Contents for Ti30

Page 4: ...Appendix B Infrared Theory Q A 92 Glossary 96 Jan 31st 2005 4 ...

Page 25: ...Man Machine Interface Flow Charts Main Loop Jan 31st 2005 25 ...

Page 26: ...Image Recording Procedure Emissivity Adjustment Procedure Jan 31st 2005 26 ...

Page 70: ...Jan 31st 2005 70 ...

Page 86: ...Jan 31st 2005 86 ...