5-16

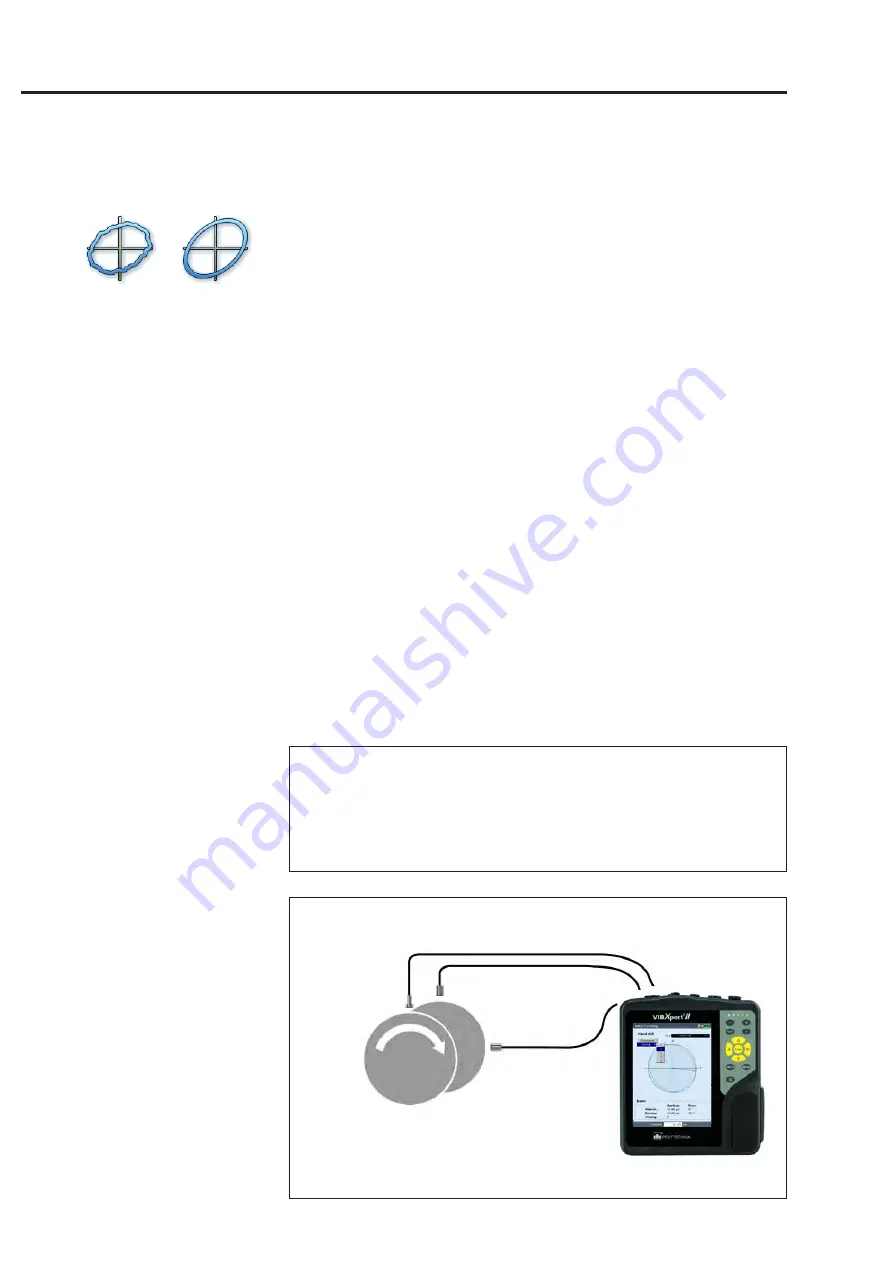

Orbit

The movement of the shaft axis* at constant speed is measured with

two non-contact sensors that are installed in an angular distance of

90 °.

This enables identification of machine faults and damage to

the shaft that become apparent in the vibration behavior of the

shaft and directly affect the path of the shaft (e.g. unbalance,

misalignment, shaft crack, rotation fault - for more details, see

VDI 3839 Sheets 1 and 2). When using 'filtered orbit', the signal is

processed in an order filter and therefore requires a keyphaser to

provide a reference.

A typical measurement installation is shown in the following figure:

- The two displacement sensors are mounted in a single

measurement plane at an angular displacement of 90° on the

machine.

If this angular displacement is not possible, you can mount the

sensors at any angular displacement between 5° and 175°.

Then enter the angular displacement in the measurement setup

('Sensor angle' parameter). However, measurement accuracy is

limited when the sensor angle

≠

90°.

- The sensor on channel A defines the X direction and the 0°

position.

- The keyphaser is mounted in the 0° position.

- Note the setting of the active edge for the trigger signal (see:

Keyphaser Menu/Device Setup, p. 2-23).

The procedure for an orbit measurement is described in the follow-

ing standards: ISO 7919, ISO 10817-1, VDI 3839 Sheet1.

A description of the measurement procedure with VIBXPERT can be

found in the Technical Information CM 18 'Analysis of radial shaft

movement in journal bearings’ - available free on our website.

Typical installation

with inductive displacement sensors

Measurement tasks

Note

filtered

unfiltered

* The movement of the shaft axis while

the machine is running up / coasting

down is recorded with a shaft center-

line plot (see p. 5-12).

Channel A

(VIB 6.640)

Channel B

(VIB 6.640)

Keyphaser

(VIB 6.631)

Summary of Contents for VIB 5.310

Page 1: ...Data Collector Vibration Analyzer VIBXPERT II Users Manual ...

Page 9: ...1 8 Empty page ...

Page 51: ...2 38 Empty page ...