OPERATING INSTRUCTIONS

20

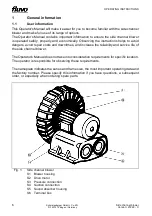

Side channel blower

Version: 27222 - C

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

•

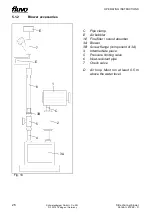

Always avoid fittings in pipelines that close suddenly (rapidly). Pressure peaks which

occur as a result of these fittings may exceed the maximum permissible housing

pressure of the side channel blower several times over! To avoid strong pressure

peaks, install pressure absorbers or air chambers

3.3.4

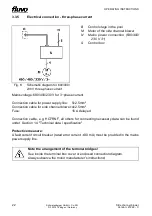

Electrical connection - general

The electrical connection for the side channel blower should only be made by a company

specialising in electrical systems that is approved by the power provider, taking into

consideration the technical connection requirements.

Note!

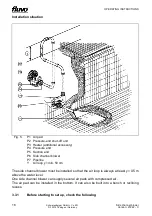

After assembly is complete or before starting up the system, the containers,

pipelines and connections must be thoroughly cleaned, rinsed and blown out

with air.

Often welding beads, pipe scale and other impurities do not come loose until

some time has passed. They must be kept out of the pipe by installing a sieve

in the suction line of the side channel blower. The open cross-section of the

sieve must be at least three times the cross-section of the pipeline to prevent

too much resistance from building up due to trapped foreign objects.

Experience shows that hat-shaped sieves containing a mesh wire net with a

mesh size of 2.0 mm and a wire diameter of 0.5 mm and made of corrosion

resistant material are effective.

Connection tasks must only be performed by a certified installation electrician,

who is approved by the responsible power provider as a specialist in electrical

installation.

For additional details, see the TAB of EVS, VBG 4 (§3) and DIN VDE 1000-10

/ 1995-5.

Applicable DIN VDE regulations 0100 and for explosion protection 0165 must

be observed.

Danger of lethal electrical shock!

Danger of electrical shock if the installation is not performed properly!