OPERATING INSTRUCTIONS

8

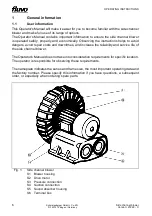

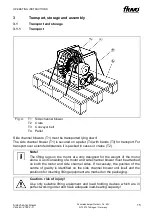

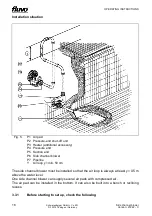

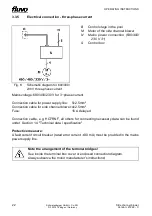

Side channel blower

Version: 27222 - C

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

1.2

Proper use

The side channel blower is intended exclusively for conveying clean air and must only be

used in accordance with the original specification. It must only be operated with the values

defined in this Technical Documentation regarding conveying medium, flow rate, speed,

density, pressure, temperature, motor power or other data defined in the specification. Any

other or more extensive use is considered improper use. The manufacturer shall not be

liable for any resulting damage.

The permissible conveying medium temperature for the standard design is -30° to +40°C.

Solids or other impurities contained in the conveying medium must be filtered out before

the medium enters the side channel blower.

The maximum ambient temperature must not exceed +40°C. The minimum ambient

temperature must be at least -20°C.

The side channel blower is not suitable for setting up in a potentially explosive atmosphere.

If the side channel blower will be used for any purpose other than what is prescribed in the

specification, always consult with the manufacturer. We will be pleased to determine what

adjustments would be required for the new intended use.

Conversions and changes to the side channel blower are not permitted!

Proper use also includes observing the Operator's Manual.

1.3

Other applicable documents

Each side channel blower has various documents which belong together with the

Technical Documentation for the side channel blower. They are:

•

The Operator's Manual for the side channel blower

•

The Operator's Manual for the drive

•

The Operator's Manual for the accessories listed in the specification

•

Acceptance reports from TÜV, etc.

•

Test run report

•

Performance run report

•

Assembly drawing (dimension sheet)

•

Test certificate for (ex) design

•

Declaration of Conformity

•

Specification with all information

Not all the documents named above exist or are included in every case. Observe the

information in the specification in this regard.