Pump memory

The pump memory is located inside the pump's junction box. The memory is loaded with data from the

factory, which is then uploaded to the MAS system at first startup.

The data that is uploaded contains the following features:

• Data plate information

• Sensor types and manufacturer's recommended alarm settings

• Operational data and data to support service:

• Histograms of temperatures, vibrations, and cycle length

• Start and stop registration

• Service log with a maximum of 200 lines of text

• Conditions to prompt for service based on e.g. running time, number of starts and stops or specific

dates

For more information, see the Installation and User Manual for the MAS 711 monitoring systems.

The cooling system

The cooling system removes the heat generated by the motor. Most of the heat is transferred to the

surrounding media (i.e. out of the motor) through the stator housing. The table below gives an overview of

the various cooling systems.

Cooling system type

Description

Direct cooling (no

cooling jacket)

The pump is fully submerged and directly cooled by the surrounding water.

Integrated cooling

(cooling jacket)

A portion of the pumped liquid is circulated from the pump housing through

the cooling jacket. This allows the pump to work continuously at output

regardless of whether the pump above of below the surface of the liquid.

External cooling (cooling

jacket)

The cooling jacket is sealed off from the pump housing and connected to a

separate (external) cooling system.

For more information regarding the versions please contact your ITT representative.

NOTICE:

Always operate the pump with the drive unit completely submerged in the pumped liquid, if the pump is

delivered without the integral drive unit cooling jacket. When emptying the sump, the lowest liquid level

must not be lower than the top of the pump housing. Contact your local ITT representative for more

information.

Direct cooling

In direct cooling, the pump is submerged in the liquid being pumped.

For direct cooling to be used, the pump must be completely submerged during normal operation.

On certain occasions, for example when emptying a sump, partial submersion is allowed. The allowable

time for this is limited by several factors, such as ambient temperature, size of the sump, inflow, outflow

and so on. For more information please contact your ITT representative.

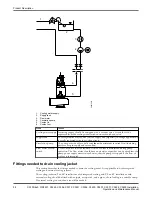

Integrated cooling

With integrated cooling, a portion of the pumped liquid is circulated from the pump housing through the

cooling jacket. The pumped media removes the heat from the motor, and then returns to the pump

housing, where it re-joins the main stream of liquid being pumped.

This cooling system is designed to tolerate a range of water qualities, up to and including municipal

sewage. Larger particles and other contaminants in the pumped liquid are kept out of the cooling jacket by

a narrow gap between the guide ring and the impeller.

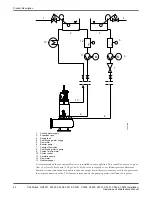

System

The figure below shows the various parts of the integrated cooling system.

Product Description

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual

33