24V

21

22

9

38

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

37 36 35

10 11 12

FOO126A

Ethernet

Ext.1

Local

Power

A

B Go

MAS 711

Monitoring and Status

TD

TD

RD

RD

TD RD

Ext.2

Link LAN

19 7

1

20

18

14

17 16 13 8

5

3

15 4 6

2

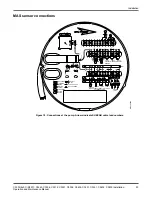

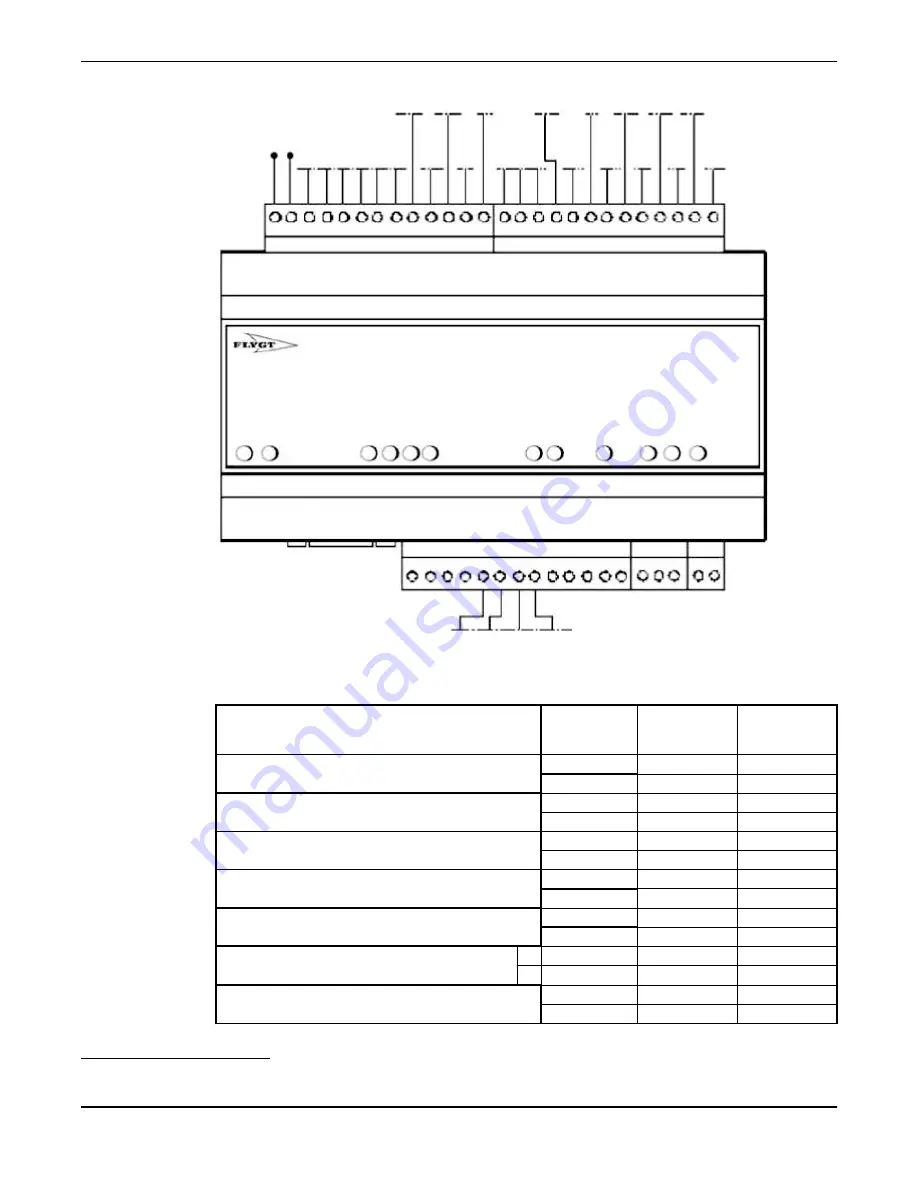

Figure 19: Connections at the MAS 711 base unit

This table shows how the conductors are connected to the different sensors.

Sensor

Terminal

block

Conductor

number for 12-

lead cable

Conductor for

24-lead cable

Float switch in the stator housing

3

1

1

1

2

2

2

Float switch in the junction box

9

7

7

2

—

—

Pt100 in the main bearing

4

3

3

3

4

4

4

Pt100 in the support bearing

37

—

17

38

—

18

Thermal switches or thermistors in the stator

5

5

5

6

6

6

CLS sensor in the oil housing

+

33

—

19

–

34

—

20

Pt100 in the stator winding 1

19

8

8

4

—

—

3

The leakage sensors in the stator housing and the junction box use the same terminal (terminal 2) on the terminal block.

4

The Pt100 sensor in the main bearing and the support bearing use the same terminal (terminal 4) on the terminal block

Installation

54

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual