NTSCGE-

WTOEUS

L2 L3

L1

GC

3~

V1

U1

W

V

U

L2

L1

L3

GC

GC

W1

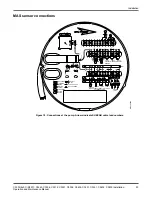

Figure 39: Schematic diagram

W

V

U

L2

L3

L1

Figure 40: Connection diagram

Cable bending radius, weight and diameter

This table shows the minimum bending radius, weight and outer diameter for SUBCAB

®

control cables.

Table 14: SUBCAB

®

control cables

Cable

Minimum bending

radius in mm

Weight in kg/m

Outer diameter,

minimum-maximum in

mm

12x1.5 mm

2

190

0.53

Ø 18.2–21.2

24x1.5 mm

2

250

0.90

Ø 24.9–28.9

S12x1.5 mm

2

300

0.78

Ø 29.9–31.0

S24x1.5 mm

2

350

1.59

Ø 33.0–37.0

This table shows the minimum bending radius, weight and outer diameter for SUBCAB

®

power cables.

Table 15: SUBCAB

®

power cables

Cable

Minimum bending

radius in mm

Weight in kg/m

Outer diameter,

minimum-maximum in

mm

4 G 16 mm

2

260

1.25

Ø 26.0–28.0

4 G 25 mm

2

320

1.9

Ø 32.5–34.5

4 G 35 mm

2

360

2.5

Ø 36.5–38.5

4 G 50 mm

2

410

3.4

Ø 41.0–45.0

4 G 70 mm

2

450

4.5

Ø 45.0–49.0

4 G 95 mm

2

500

5.8

Ø 54.0–58.0

4 G 120 mm

2

600

7.3

Ø 56.0–60.0

This table shows the minimum bending radius, weight and outer diameter for SUBCAB AWG power

cables.

Installation

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual

65