5. Examine if the guide bar tip is rough or very worn.

(Fig. 125)

6. Make sure that the bar tip sprocket turns freely and

that the lubricating hole in the bar tip sprocket is not

blocked. Clean and lubricate if it is necessary. (Fig.

126)

7. Turn the guide bar daily to extend its life cycle. (Fig.

127)

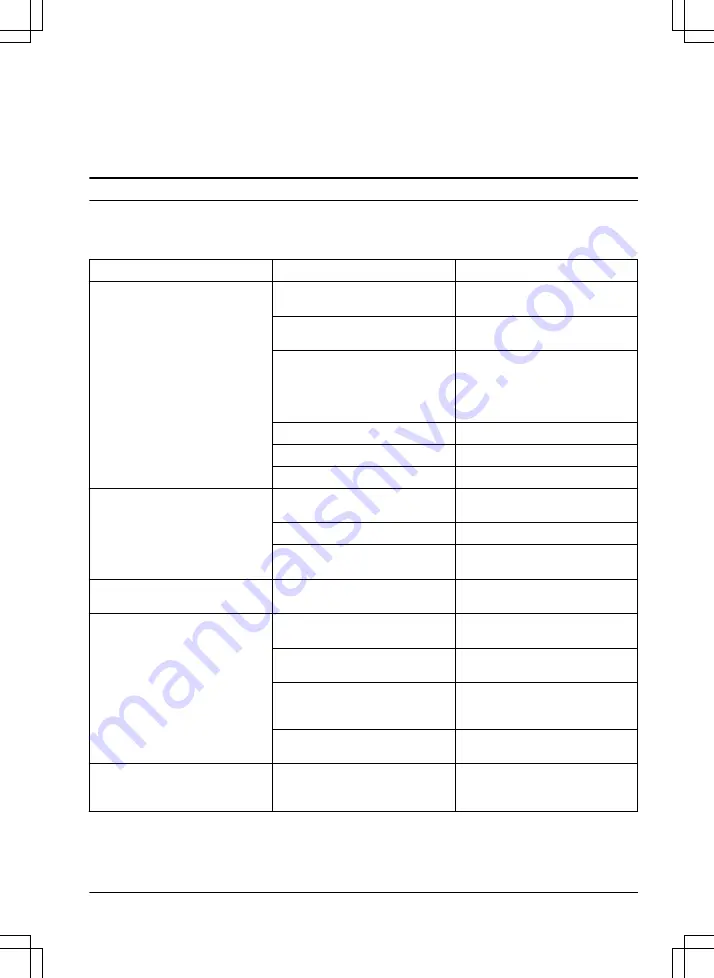

Troubleshooting

Troubleshooting

Problem

Possible cause

Action

The product does not start.

There is no power in the mains.

Make sure that there is power in the

mains.

The power plug is not connected cor-

rectly.

Make sure that the power plug is

connected correctly.

The power cord, power plug, or ex-

tension cord is damaged.

Make sure that the power cord, pow-

er plug and eventual extension cord

are not damaged. If the power cord

is damaged or defective, speak to an

approved service agent.

The saw chain brake is engaged.

Disengage the chain brake.

The cut-out switch is engaged.

Disengage the cut-out switch.

The product is defective.

Speak to an approved service agent.

The motor does not turn or loses

power.

The saw chain or the guide bar is not

assembled correctly.

Make sure that the saw chain and the

guide bar are assembled correctly.

The product is defective.

Speak to an approved service agent.

The saw chain is not tensioned cor-

rectly.

Make sure that the saw chain has the

correct tension.

The motor operates irregularly or at

reduced speed.

The product is defective.

Speak to an approved service agent.

The cutting result is unsatisfactory

The saw chain or the guide bar is not

assembled correctly.

Make sure that the saw chain and the

guide bar are assembled correctly.

The saw chain is not tensioned cor-

rectly.

Make sure that the saw chain has the

correct tension.

The saw chain is not lubricated.

Make sure that the saw chain is lubri-

cated. Refer to

saw chain lubrication on page 22

.

The saw chain is not sharp.

Sharpen the saw chain. Refer to

sharpen the saw chain on page 21

.

The chain brake is engaged but the

saw chain does not stop.

The chain brake is defective.

Do not operate a product with a de-

fective chain brake. Speak to an ap-

proved service agent.

1810 - 001 -

23

Summary of Contents for EasiSaw 350E

Page 1: ...EasiSaw 350E EN Operator s manual 8 27...

Page 3: ...21 22 23 24 25 26 27 28 B A 29 30 31 32 33 34 35 B A 36 37 38 39 40 41 42 43 A 44...

Page 4: ...45 A G F B D E C 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 A B C 61 62 63 64 65 66 67...

Page 7: ...124 125 126 127...

Page 28: ...www flymo com Original instructions 1142984 26 Rev A 2022 09 22...