Assembly Instructions

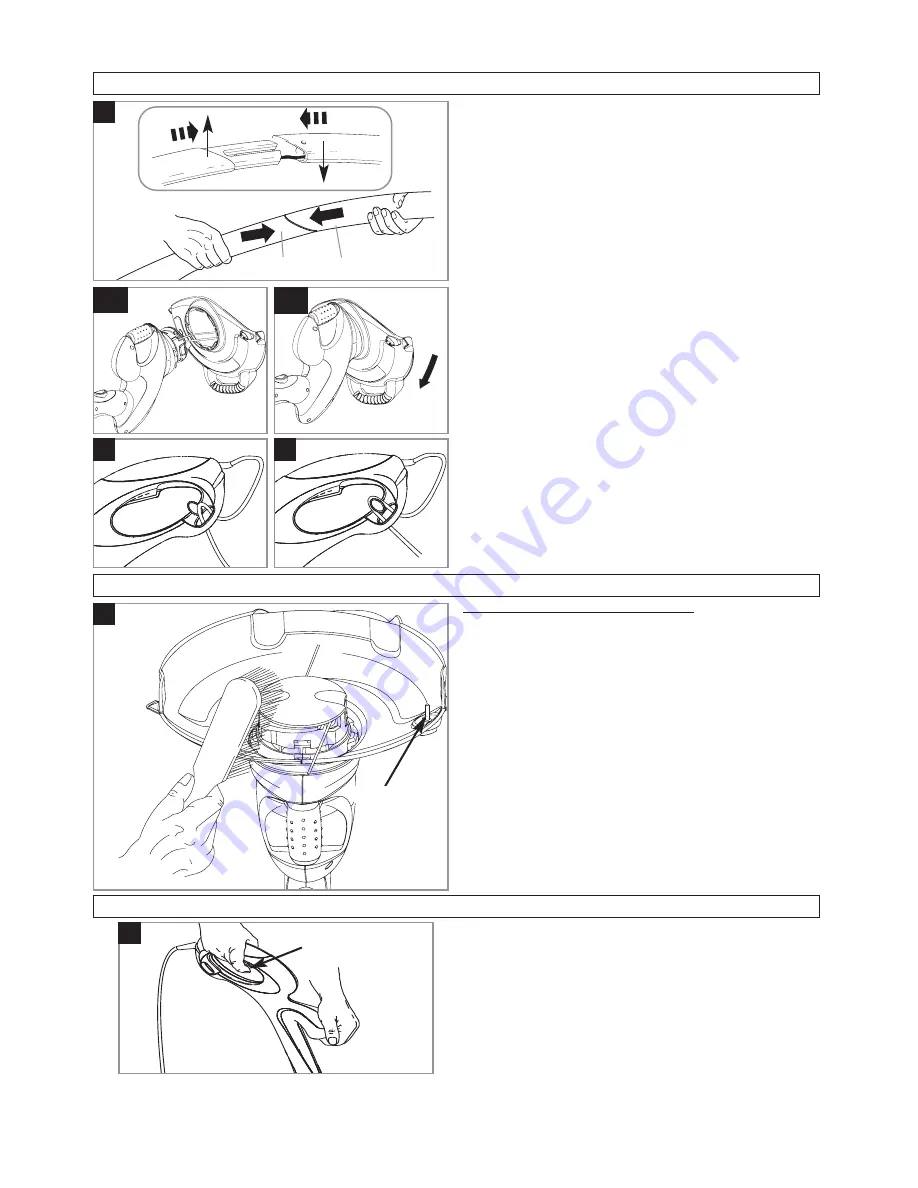

Shaft Assembly (A)

1. Locate the lower shaft (A1) into the upper shaft (A2).

2. Grasp firmly and hold steady the lower shaft. Locate

the upper shaft and snap together firmly.

•

The unit is correctly assembled when the gap be-

tween the upper and lower shaft has been closed.

Safety Guard Assembly (B1) & (B2)

1. Locate the safety guard over the cutting head. Ensure

the nylon line is fed through the hole in the safety

guard as illustrated in fig B1.

2. Push into location and turn safety guard in the direc-

tion illustrated in Fig B2, until a click is heard and the

safety guard is securely locked in position.

•

ENSURE THE SAFETY GUARD IS SECURELY IN

PLACE BY ATTEMPTING TO TWIST GUARD.

Cable Restraint (C) & (D)

1. Form loop in mains cable and push the loop through

the slot as illustrated in picture (C).

2. To secure, position loop over the hook and pull the

cable back through the slot as illustrated in picture (D).

A

1

2

Starting and Stopping

1

2

C

D

F

WARNING

Cutting head continues to rotate after the trimmer has

been switched off.

To start your trimmer

Squeeze the switch lever (F).

To stop your trimmer

Release the switch lever (F).

B2

B1

Double Auto Feed System

How the automatic line feed works (E)

1. When initially switching on the trimmer, a small length

of line is fed out.

2. A ‘clattering’ noise will be heard when the two nylon

lines hit the line cutter. DO NOT BE ALARMED this is

quite normal. After approximately 5 seconds the line

will be cut to the correct length and the noise will re-

duce as the motor reaches full speed.

•

Make sure the motor is up to full speed before trim-

ming or edging.

3. If the noise of the nylon line being cut cannot be heard,

more line will need to be fed out.

4. To feed more line, it is first necessary to to allow the

motor to stop completely, then re-start, allowing the

motor to reach full speed.

5. Repeat step 4. until you hear the lines hitting against the

cutter. (Do not repeat this procedure more than 6 times)

6. If problems are experienced with the automatic line

feed refer to Fault Finding Chart.

E

line cutter