www.fmiproducts.com

122272-01D

10

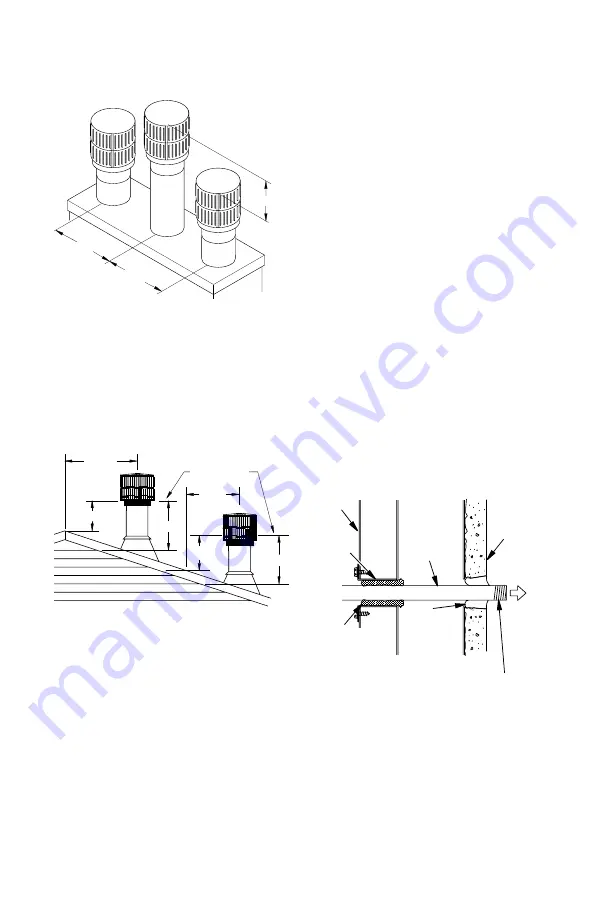

10 FOOT RULE

All flue gas outlet chimney terminations must

extend a minimum of 3 feet in height above

highest point where it passes through the roof

and must be at least 2 feet above highest point

of the roof that is within a horizontal distance

of 10 feet (see Figure 17).

installation

Continued

FINISHING FIREPLACE

Combustible materials, such as wallboard,

gypsum board, sheet rock, drywall, plywood,

etc. may make direct contact with sides and

top around the fireplace face. It is important

that combustible materials do not overlap face

itself. Brick, glass, tile or other noncombustible

materials may overlap front face provided they

do not obstruct essential openings like louvered

slots or any other opening. When overlapping

with a noncombustible facing material, use only

noncombustible mortar or adhesive.

24" Min.

24" Min.

18"

Min.

Typ.

Figure 16 - Multiple Chase Installation

10'

2' Min.

10'

3' Min.

2' Min.

3' Min.

Level of

Flue Gas

Outlet

Figure 17 - 10 Foot Rule

Seal

Opening

with

Refractory

Cement

Outside of

Fireplace

Gas

Line

Conduit

Repack

Insulation

Incoming

1/2" Black

Iron Pipe

Side

Firebrick

Finished

Side

Provide Enough Threaded

End for Fitting Connection

Figure 18 - Gas Line Installation

OPTIONAL GAS LINE

INSTALLATION

Gas line hook up should be done by your sup-

plier or a qualified service person.

Note: Before you proceed, make sure your gas

supply is turned off. Use only a 1/2" black iron

pipe and appropriate fittings.

1. Remove gas line cover plate located on

either side of fireplace and pull out insula-

tion from gas line conduit sleeve. Save

insulation for reuse. Replace screws.

2. Run a 1/2" black iron gas line into fireplace

through rear at gas line conduit sleeve (if us-

ing a raised platform, add height). Provide

sufficient gas line into fireplace chamber for

fitting connection (see Figure 18).

Note: Secure incoming gas line to wood

framing to provide rigidity for threaded

end.

3. Repack insulation around gas line and into

sleeve opening. Seal any gaps between

gas line and refractory knockout hole with

refractory cement or commercial furnace

cement, Install the gas appliance or cap-off

gas line if desired.