RTM X42.Modbus Installation Manual and Operating Instructions

09.12.2019

9

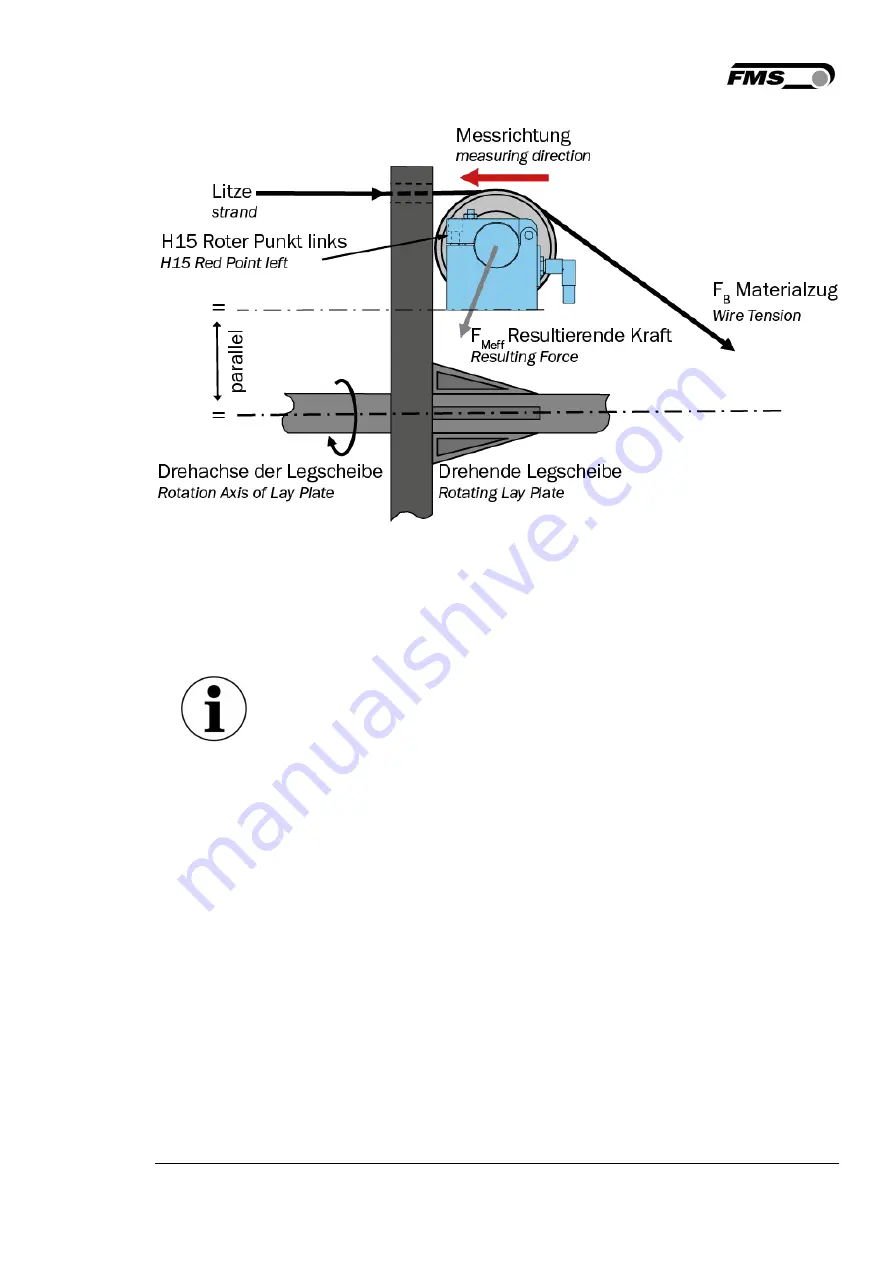

Figure 3: Force sensor alignment, here RMGZ200

RMGZ200_NEU_2017_BA_Manual.ai

Parallel alignment

The exact, parallel alignment of the measuring direction to the axis

of rotation of the machine is decisive for achieving precise measured

data.

Otherwise, measured value fluctuations occur during machine

operation due to the high sensitivity of the FMS force sensors. These

interfere with the assessment of the product quality later.

Due to irregularities in the installation surfaces, the alignment may have to be

readjusted very precisely. Some FMS force sensors feature an integrated mechanism

facilitating this fine adjustment. For force sensors without such features, we

recommend the use of shims or thin metal strips.

4.3

Installation of the Electronics Components in the Rotating Part of

the Machine

The transmitter module and the channel extension modules should be mounted as

closely as possible to the axis of rotation of the strander. This reduces the influencing

centrifugal forces.

During installation of the transmitter module, make sure that the centrifugal forces do

not act in the direction of the fastening screws of the battery.

Make also sure that the transmission path to the receiver module is free from obstacles.

Mount the receiver as high as possible.