SITE R

REQUIREMENTS

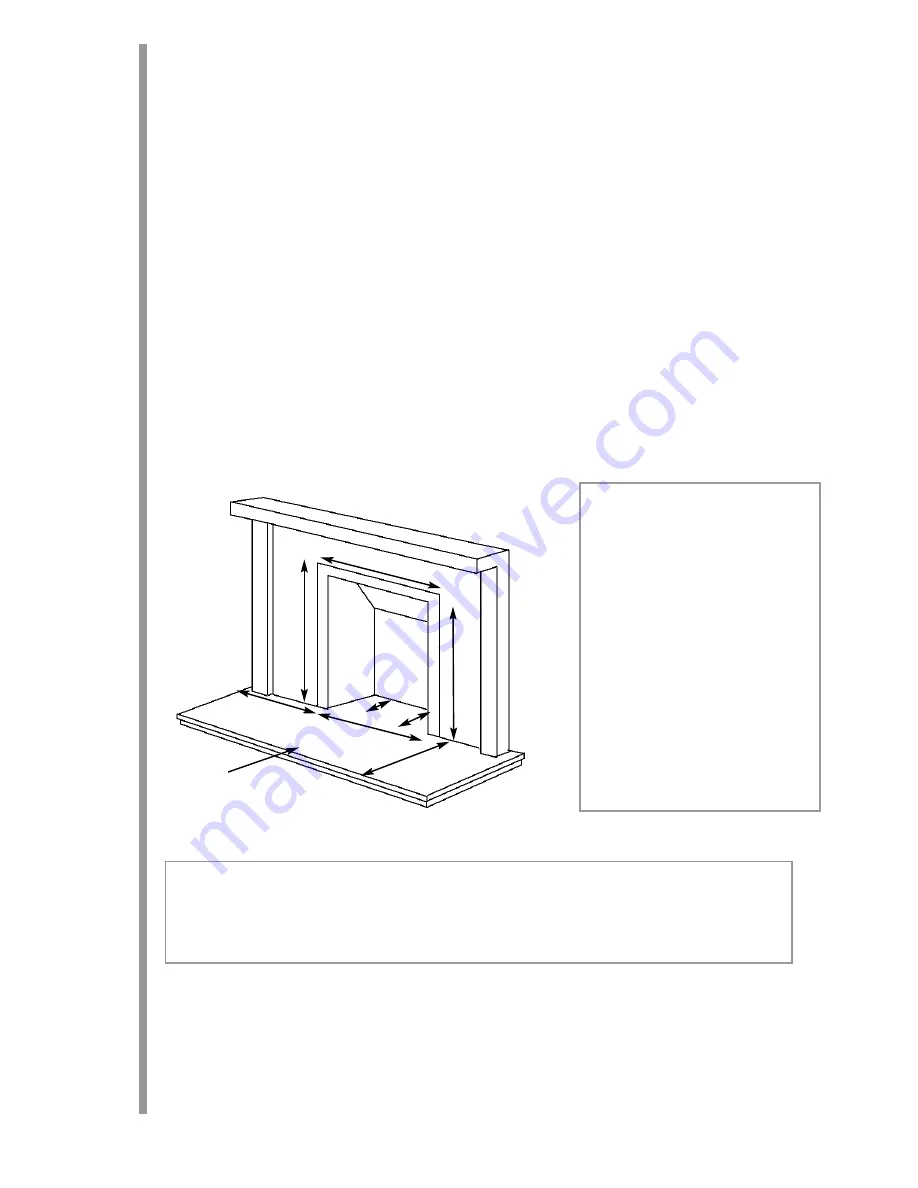

The fireplace opening should be inspected and repairs made where necessary. Any chair brick or fireback may be left in situ, providing that

the dimensional requirements for debris collection space and spigot clearances are met. See diagram below..

The opening WIDTH and HEIGHT dimensions should be between 470mm and 530mm wide, and 540mm (see nnote bbelow) to 575mm high.

Note: TThe sspigot ooutlet oof tthe ffire iis 5565mm hhigh,, bbut sshould ffit iinto tthe ggather aat tthe ttop oof tthe ffireplace aas tthe aappliance iis ffitted. A

Any m

mod-

ifications tto tthe ffireplace oopening m

must bbe tto aa hheight oof 5565mm m

min.

Opening DEPTH should be 200mm or greater for a clay/cement lined or pre-cast flue which is new, unused, or previously used only with a

gas appliance. DEPTH should be 240mm or greater for a flue used for solid fuel of oil burning appliances. Opening DEPTHS include any plas-

ter or infill panels which form part of the installation.

This appliance requires a natural draught flue system which may be one of the following;

225mm x 225mm (9in x 9in) brick or stone.

175mm (7in) minimum diameter lined brick or stone.

175mm (7in) minimum diameter twin wall flue conforming to BS 715.

Any existing under grate draught device must be sealed off. The opening wall must be non-combustible.

The appliance requires a hearth with non-combustible surface of at least 12mm thick. The top surface must be at least 50mm above the sur-

rounding floor level, or be surrounded by a raised edge or fender 50mm high.

To enable the products of combustion to be cleared properly up the flue, the outlet at the back of the appliance must have a 50mm mini-

mum clearance between it and the back wall of the opening or any other obstruction. The area immediately above the outlet must form a

smooth path into the flue.

Any type of fire surround used with this appliance must be adequately sealed to the wall and floor.

A combustible shelf may be fixed to the wall above the fire, providing that it complies with the dimensions given below.

A non-combustible shelf may be fitted to within 10mm of the top edge of the fireframe. Combustible materials, such as wood, may be fitted

to within 100mm (4in) of either side of the fireplace opening, providing the forward projection does not exceed 100mm (4in).

Any combustible side walls must be at least 500mm to the side of the radiant heat source.

As with all heating appliances, any decorations, soft furnishings, and wall coverings (i.e. flock, blown vinyl and embossed paper) positioned

too close to the appliance may discolour or scorch.

3

A

C

D

B

E

F

4.0

G

H

X

A. Opening height: 540mm min/575 mm max.

B. Opening width: 470mm min/530mm max.

C. Mounting depth: 180mm

D. Hearth must extend minimum of 150mm either

side of the opening.

E. Hearth must extend minimum of 300mm in

front of the opening.

F. Non-combustible hearth must be a minimum of

50mm in height, or be surrounded by 50mm high

fender.

G. 550mm, this area must be flat and vertical to

ensure a good seal.

H. 585mm, this area must be flat and vertical to

ensure a good seal.

X. Debris collection space - See section 4.1 on fol-

lowing page.

Maximum ddepth oof sshelf

M

Minimum ddistance ffrom ffinished hhearth

surface tto uunderside oof sshelf

100mm (4in)

745mm (29 1/4 in)

150mm (6in)

845mm (33 1/4 in)

203mm (8in)

895mm (35 1/4 in)

Summary of Contents for 18" High-Tech

Page 1: ......