FIREFRONT

This fire is supplied with a particular style of firefront. Use of the firefront will ensure an adequate airflow under

the firebed for the correct functioning of this appliance.

Compliance with safety standards cannot be guaranteed if another style of front is used.

CLEARANCES TO COMBUSTIBLES

A combustible shelf may be fixed to the wall above the fire, providing that it complies with the dimensions given

below.

A non-combustible shelf may be fitted to within 10mm of the top edge of the fireframe.

Combustible materials, such as wood, may be fitted to within 100mm (4in) of either side of the frame of the

appliance, providing the forward projection does not exceed 100mm (4in).

Any combustible side walls must be at least 500mm to the side of the radiant heat source.

As with all heating appliances, any decorations, soft furnishings, and wall coverings (i.e. flock, blown vinyl and

embossed paper) positioned too close to the appliance may discolour or scorch.

VENTILATION

No purpose provided ventilation is normally required for this appliance.

The requirements of other appliances

operating in the same space or room, and the results of a spillage test must be taken into consideration when

assessing ventilation requirements, this will have been carried out by your CORGI registered installer.

For Republic of Ireland, ventilation may be required, see IS 813, ICP3, IS 327, and any other rules in force.

OPERATING INSTRUCTIONS

The pilot is visible through the underside of the left hand side of the matrix.

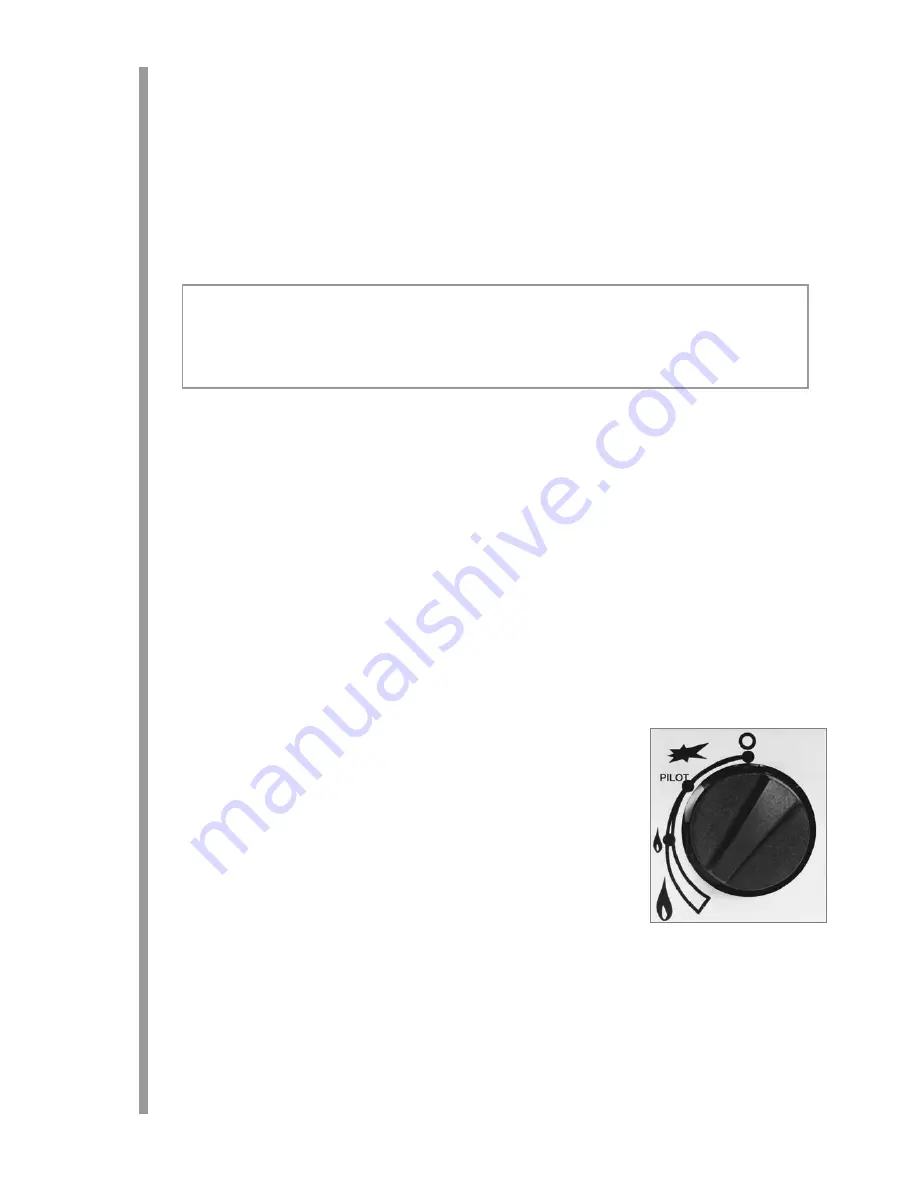

Push in and turn the control knob to the SPARK position, and hold there for a

few seconds.

Continue turning anti-clockwise through the spark click to the PILOT light

position, ensuring the pilot has lit. If not, return the knob clockwise, and repeat.

When the pilot lights after the spark, keep the knob depressed for

approximately ten seconds. Now release the knob and the pilot should stay

alight. If the pilot is extinguished during use, wait three minutes before

repeating the ignition procedure.

To achieve the HIGH setting, push the control knob in slightly and continue turning anti-clockwise to the high

position. The main burner should light after a few seconds.

To decrease the setting to LOW, turn the control knob clockwise to the low setting.

To turn to the PILOT position from the HIGH or LOW positions, press the control knob in, and return to the pilot

position and release.

To turn the fire OFF, keep the knob pressed in, return to

the off position and release.

2

Maximum depth of shelf Minimum distance from inside edge of

fire frame to underside of shelf

100mm (4in)

203mm (8in)

150mm (6in)

305mm (12in)

203mm (8in)

356mm (14in)

2.0

3.0

4.0

5.0