PREFABRICATED FFLUE BBOXES

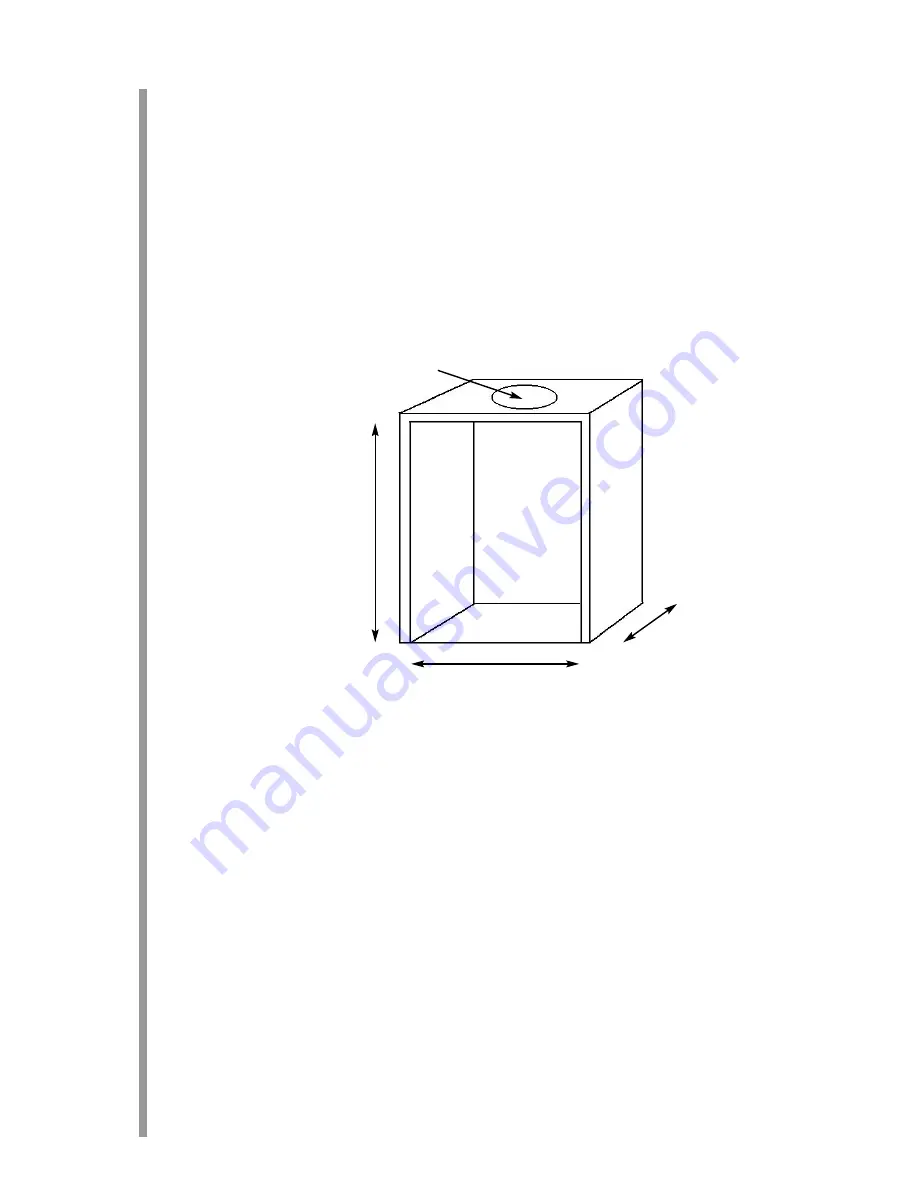

This appliance can be fitted into a number of proprietary flue boxes provided that the minimum dimensions given

in the diagram below are complied with.

Consstrucctional N

Note: The frame of the fire, any back panel or other infill panels, and the flue box must be sealed

together so that there is no possibility of leakage between them. Adequate clearances to combustible materials

(e.g. false chimney breast construction) must be maintained.

The m

manufaccturerss’ iinsstrucctionss ffor ffittingg tthe pprefabriccated bbox sshall bbe ccomplied w

with aat aall ttimess.

To fit the fire using the cable fixing kit, some minor adaption may be necessary for certain flue boxes.

A check should be made to ensure the firebox does not obscure the flue box outlet.

The firebox, base of the flue box, and hearth below may be drilled to allow plugs and screws to secure

installation.

It is important that the sealing requirements of the appliance are met at all times and that the flue box is well

sealed to any back or infill panel.

Note: The DEPTH dimension is inclusive of any back or infill panel.

UNPACKING THE APPLIANCE

Stand the carton the right way up, cut the strapping bands and remove the top endcap. Read all the instructions

before continuing to unpack or install this appliance.

Remove the box containing the cast front fret, and the bags containing the coals. Remove the cardboard packing

pieces, and any other bags or boxes containing fittings or other parts. When all loose parts have been removed,

the outer sleeve may be lifted off to reveal the appliance. Check that the components supplied correlate with the

component checklist given in section 7.1. Please dispose of all the packaging materials at you local recycling

centre.

5

125mm min internal

dia twin wall flue

505mm min

opening height

300mm min

opening width

140mm

min depth

6.0

7.0