37

Handler I, II & III Operator’s Manual - October 2008

Problem

Cause

Solution

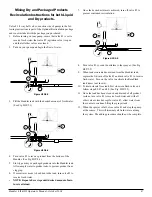

Chemical is splashing

Improper handling of jugs

Apply constant, even pressure when puncturing the con-

tainer. Don’t force the jug onto the knife assembly.

Dull blade

Resharpen the knife assembly by removing the assembly

and hand sharpening with a file or grinder.

Suction line is drawing air

Incorrect valve settings

Reduce suction from the Handler tank by partially closing

the suction valve. This will regulate the speed at which the

mixture is drawn from the Handler. Once all of the liquid

has been drawn from the tank, shut off the suction valve.

Pump is cavitating

Incorrect valve settings

Reduce suction from the Handler tank by partially closing

the suction valve. This will regulate the speed at which the

mixture is drawn from the Handler. Once all of the liquid

has been drawn from the tank, shut off the suction valve.

Clogged suction lines or venturi

Granular product is insufficient-

ly dissolved

Force water back into the venturi by opening the bypass

valve. This allows water to back up into the Handler tank

and dislodge any obstructions.

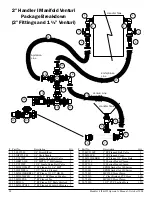

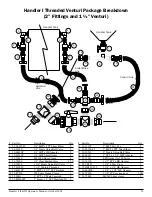

Threaded fittings leak

Improper sealant usage

It is important the manufacturers instructions for use are fol-

lowed. As a reminder:

Store and apply between 20 F and 140 F to clear ta-

pered threads.

For pipe diameters up to 1 1/4”, apply thick even coat

to male threads only. For large sizes apply to both male

and female threads.

For up to 2” pipe, tighten up to 3 full turns past hand

tight and for larger sizes up to 2 full turns. Additional

tightening may be required but do not overtorque to

stretched condition.

Cure time may vary with application and service condi-

tions - normally 24 hours.

1.

2.

3.

4.

Hose is difficult to install

Heat the hose in boiling water until soft. Slide on to hose

barb fitting. If necessary, hose lubricants and silicone are

available and can be used if compatible.

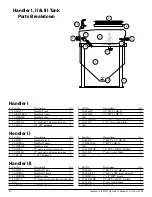

Tank calibration not accurate

Tank is not level

Level the system.

Fittings and line volumes not

accounted for

The tank calibration marks indicate the volume of the tank,

but do not take into account added volume in the lines and

fittings. Pre-calibrate the volume of your lines and fittings

to get more accurate readings.

Inside of tank dirty

Regular use

See the section of this manual that covers cleaning the tank

Contamination in optional recircu-

lation line

Improper rinsing/cleaning

Add a second ball valve on the bottom of the tank to com-

pletely isolate the line returning to the pump.

Summary of Contents for Handler I

Page 2: ......

Page 48: ...48 Handler I II III Operator s Manual October 2008...