28

Handler I, II & III Operator’s Manual - October 2008

Operation

To the new operator or owner

It is the responsibiity of the owner or operator to read and under-

stand this manual, the sprayer manual and the chemical container

label before starting. Follow all safety instructions exactly.

Safety is everyone’s business. By following recommended pro-

cedures, a safe working environment is provided for the opera-

tor, bystanders and the environment.

Many features incorporated into this equipment are the result

of suggestions made by customers like you. Read the manual

carefully to learn how to operate the machine safely, and how to

set it to provide maximum efficiency. By following the operating

instructions in conjunction with a good maintenance program,

your Handler will provide many years of trouble-free service.

Operating Safety

Warning

Read and understand the Operator’s Manual and all

safety signs before operating, maintaining, adjusting or

unplugging the Handler.

Read chemical manufactures’ warnings, instructions

and procedures before starting and follow them exactly.

Do not put hands into the Handler when adding product.

Wear safety goggles, rubber gloves and protective cloth-

ing whenever working with the Handler or on a machine

or a component containing toxic product.

Keep all shields and guards in place when operating.

Clear the area of all bystanders, especially children,

before starting.

Review safety instructions annually.

•

•

•

•

•

•

•

How the System Works

Liquid product in containers

A sharp point and 4 blades are located inside the Handler tank to

puncture and split open the bottom of a container. As the bottom

of the container opens, fresh water is allowed to flow into the

container for rinsing.

Fresh water enters the bottom of the container from a line

through the side of the eductor tank. Valves in the plumbing con-

trol the removal of the contents of the tank and allow fresh water

to enter for rinsing the unit.

Mixing and removal of chemical from the Handler unit is ac-

complished using a venturi valve system.

Liquid bulk product

Each Handler tank is calibrated with high visibility, accu-

rate markings to easily measure product pumped from a bulk

container. The bulk product is pumped into the Handler tank

through the lid, or through a special closed fitting adapted to the

Handler’s lid.

Dry product

Each Handler tank comes with an agitation nozzle. When com-

bined with the venturi or the recirculation package, the user can

easily mix dry product.

The venturi

The venturi system operates on principles of suction. As water

is being pumped through the venturi, a suction is created which

draws the tanks contents from the tank, simultaneously provid-

ing fresh water to rinse the container.

With the venturi system only one pump is required to operate the

system. The pump is always placed before the venturi and the

Handler.

Break In

Although there are no operational restrictions on the Handler

when used for the first time, it is recommended that the follow-

ing mechanical items be checked:

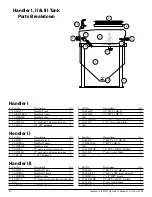

Summary of Contents for Handler I

Page 2: ......

Page 48: ...48 Handler I II III Operator s Manual October 2008...