44

Handler I, II & III Operator’s Manual - October 2008

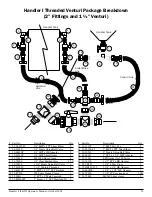

Plumbing Package

Assembly

(Handler 3)

Overview

Although not very common, some customers prefer to purchase

and use the Handler as an induction system rather than an educ-

tion system. In the induction system the venturi is removed and

the pump is used to both pressurize the system when adding

fresh water through agitation and when rinsing containers with

fresh water, and to remove mix liquids and concentrated chemi-

cal solutions from the tank. This appendix to the Handler I, II

& III manual gives assembly and operational instructions for

the Handler III plumbing package systems offered by Focus

Industries.

Assembly & Installation

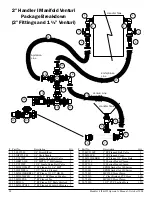

Handler III 2” Manifold Plumbing

Figure H3P-4.1

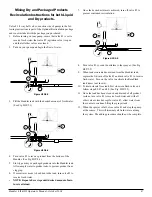

Thread (without using sealant) 2” FPT x 2” hose barb 90

degree, 10-10930 to anti-vortex fitting on tank bottom. Turn

hose barb to desired position and tighten fly-nut. (See Fig

H3P-4.1)

NOTE: Check flynut on anti-vortex fitting and tighten as

necessary with pump pliers. Do not overtighten.

1.

•

Figure H3P-4.2

Assemble 2” plumbing package. (See Fig H3P-4.2)

Install plumbing assembly to venturi bracket using bolts and

U-bolts provided. Tighten.

Figure H3P-4.3

Measure, cut and install 1” hose (See Fig H3P-4.3) con-

necting agitation/rinse assemblies and RotaFlush to cross.

Secure hose with clamps.

Attach customer supplied 2” suction hose to 2” hose barb

assembly on tank bottom. Secure with clamps provided.

Check and tighten all clamps and bolts as necessary.

NOTE: For optional recirculation package

installation instructions see page 26.

2.

3.

4.

5.

6.

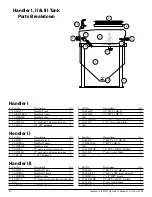

Summary of Contents for Handler I

Page 2: ......

Page 48: ...48 Handler I II III Operator s Manual October 2008...