444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

4 0

11. Maintenance

Information

At normal use maintenance on the vehicle lift must be carried out once a year.

At more than average use, i.e. more than 20 lifting sessions per day, we

recommend that maintenance is done every six months in order to maintain the

safety and the value of the vehicle lift:

•

Cover the spindles with grease.

•

Check (or replace) gliding units of the lifting carriages for wear and tear.

•

Lubricate gliding tracks of the lifting carriage gliding units.

•

Grease lifting arm sections, carrying bolt and locking devices.

•

Grease turntable spindles, check anti-twist devices.

•

Check (or replace) rubber washer of the turntable.

•

Check (replace) gliding units of the lifting arms.

•

The wear and tear size between the lower edge of the cage ring and the upper edge at the shaft of

the safety nut is to be checked.

•

Check (or replace) function and condition of the locking devices of the lifting arms.

•

Check the function of the analogue path measuring initiator.

•

Check initial tension and condition of the ribbed V-belts, adjust tension and, if necessary, replace them.

•

Check all screw connections.

•

Check the dowel connection with a torque wrench.

The exchange of load bearing parts and control components must always carried out by an expert to ensure

that the stipulated values, which are necessary for perfect operating of the vehicle lift, are adhered to.

Otherwise the life span of the exchanged parts and the overall function would be limited.

For statutory inspections we recommend entering into a maintenance

contract (safety checks and maintenance) with one of our authorised customer

service partners. Only he may enter test results into the record book and present

you with an “HAK” test plaque which confirms the safety and functioning of the

vehicle lift.

Information

Summary of Contents for 442 9020

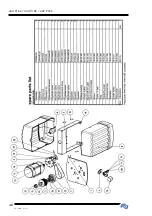

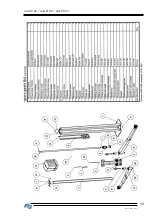

Page 13: ...444 9160 444 9180 442 9020 13 E 219 GB Issue 1 ...

Page 14: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 14 ...

Page 15: ...444 9160 444 9180 442 9020 15 E 219 GB Issue 1 ...

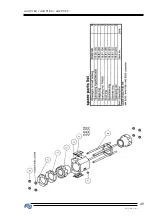

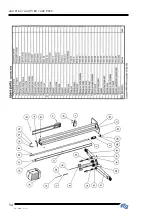

Page 17: ...444 9160 444 9180 442 9020 17 E 219 GB Issue 1 Lifting arms for type 442 9020 ...

Page 21: ...444 9160 444 9180 442 9020 21 E 219 GB Issue 1 ...

Page 23: ...444 9160 444 9180 442 9020 23 E 219 GB Issue 1 ...

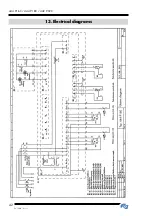

Page 42: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 42 13 Electrical diagrams ...

Page 43: ...444 9160 444 9180 442 9020 43 E 219 GB Issue 1 ...

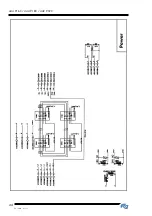

Page 44: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 44 ...

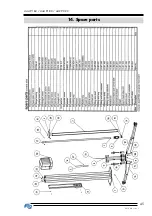

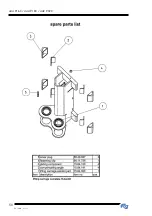

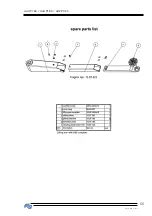

Page 45: ...444 9160 444 9180 442 9020 45 E 219 GB Issue 1 14 Spare parts ...

Page 46: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 46 ...

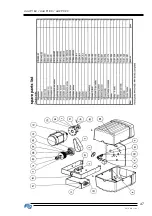

Page 47: ...444 9160 444 9180 442 9020 47 E 219 GB Issue 1 ...

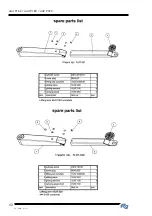

Page 48: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 48 ...

Page 49: ...444 9160 444 9180 442 9020 49 E 219 GB Issue 1 ...

Page 50: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 50 ...

Page 51: ...444 9160 444 9180 442 9020 51 E 219 GB Issue 1 ...

Page 52: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 52 ...

Page 53: ...444 9160 444 9180 442 9020 53 E 219 GB Issue 1 ...

Page 54: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 54 ...

Page 55: ...444 9160 444 9180 442 9020 55 E 219 GB Issue 1 ...

Page 56: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 56 ...

Page 57: ...444 9160 444 9180 442 9020 57 E 219 GB Issue 1 ...

Page 58: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 58 ...

Page 59: ...444 9160 444 9180 442 9020 59 E 219 GB Issue 1 ...

Page 60: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 60 ...

Page 70: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 70 ...

Page 71: ...444 9160 444 9180 442 9020 71 E 219 GB Issue 1 ...