Horizon Elite 710 Self-Contained

13

Evacuation

Evacuate the system to a level of 500 microns. When the 500 micron level is reached, close all valves. Allow the

system to sit for approximately 20 minutes. During this period the system pressure should not rise. If the system

pressure rises and stabilizes there is moisture in the system and further evacuation is needed. If the pressure

continues to rise check the system for leaks.

Ambients

Minimum

Maximum

Air temperature

1

50 F/10 C

100 F/37.8 C

Water temperature

2

45 F/7 C

90 F/32.2 C

1

Ambient air temperature is measured at the air-cooled condenser coil inlet.

2

Ambient water temperature is measured at the water feed valve inlet.

Ice capacity test

Ice machine production capacity can only be determined by weighing ice produced in a specific time period.

1. Replace all panels on ice machine.

2. Run ice machine for at least 15 minutes.

3. Move TDS switch to LOW.

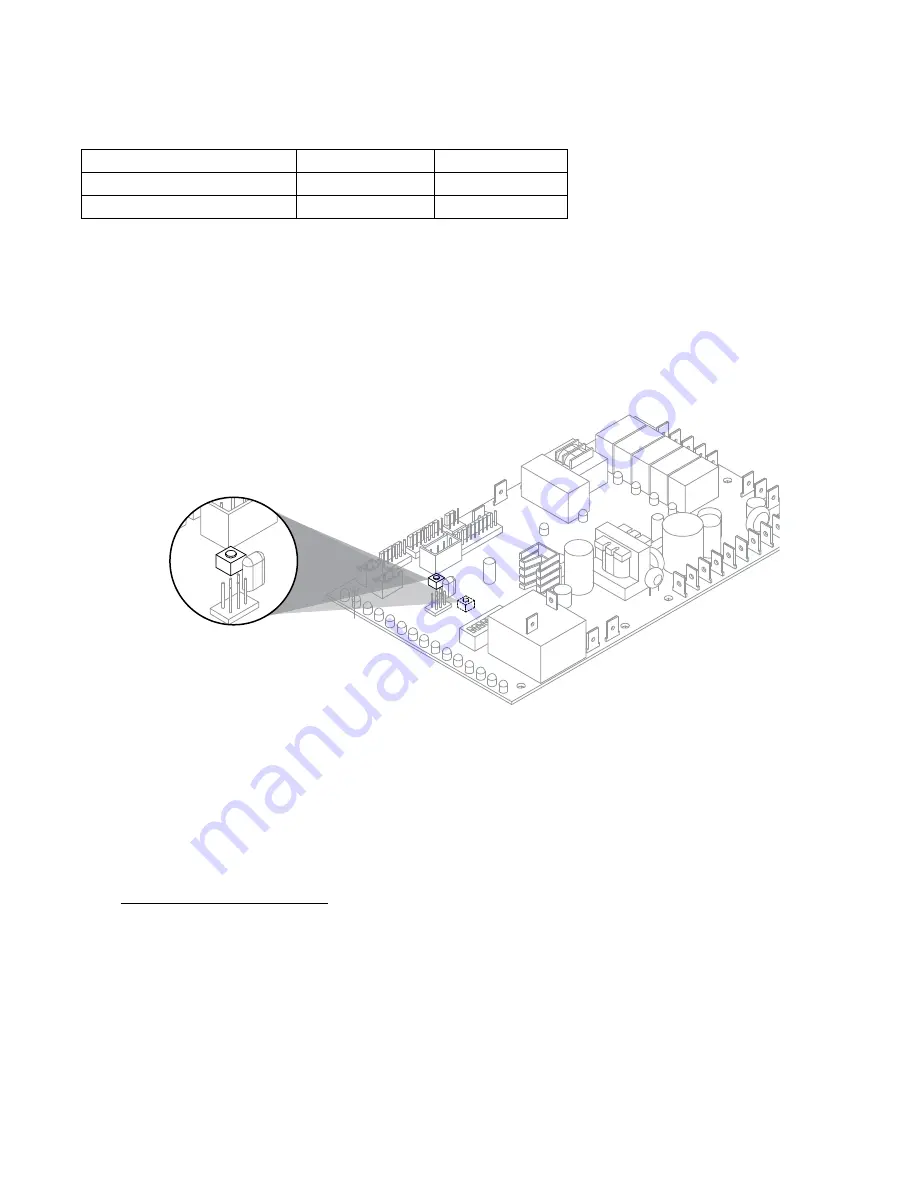

4. Press the reset button on the board.

5. Weigh and record weight of container used to catch ice.

6. Catch ice for 15 minutes.

7. Weigh harvested ice and record total weight.

8. Subtract weight of container from total weight.

9. Convert fractions of pounds to decimal equivalents (ex. 6 lbs 8 oz = 6.5 lbs).

10. Calculate production using following formula:

1440 min. x wt. of ice produced

Total test time in minutes

=

Production capacity/24 hr.

11. Calculated amount per 24 hours should be checked against rated capacity for same ambient and water

temperatures in Ice Production Tables.

12. Move TDS switch to the HI TDS position.