To start up and operate dispenser

1. Follow detailed cleaning instructions in service manual before operating dispenser.

2. For manual load units, remove front drain pan or rear lid and fill storage area with compatible ice.

3. Turn power switch located on control box to ON position.

4. For automatic fill units, follow detailed instructions in icemaker installation section of installation manual, then

turn icemaker (bin signal) switch(es) located on control box to ON position and begin to make ice.

5. When dispenser has at least 153mm of ice in storage area, press “PUSH FOR ICE” lever or button to ensure

that dispenser is operating properly.

Note:

If additional start-up information is needed, call Follett Corporation

at (610) 252-7301.

User information

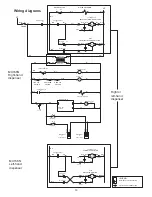

How the dispenser works

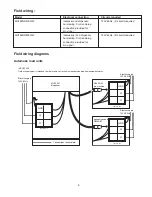

Follett’s MU155N series ice and water dispensers are available in manual load configurations (using ice from

another source) or automatic load configurations, fed from one or two Follett 400 lb (181kg)/day remote

icemakers.

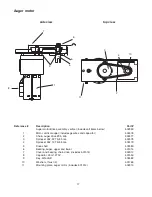

In all models, ice is stored below the counter in the dispenser storage area. When the dispense lever or button is

pushed, the dispense motor is activated. This causes the wheel assembly in the storage area to turn, moving ice

to the vertical auger assembly, which carries ice up to the dispense chute where it drops by gravity into the

container.

In automatic load units, ice is manufactured in either one or two Follett remote icemakers. These icemakers may

be located up to 6m away from the dispenser. As water freezes to the inside walls of the icemaker evaporator, a

rotating stainless steel auger removes ice and carries it to the top of the evaporator assembly where it is

compressed and extruded through an outlet port. The extruded ice is then pushed through the tube to the storage

compartment of the dispenser. A level fill circuit maximizes fill in the storage area by rotating the wheel at

intervals until the bin is completely filled. When the bin is filled, a bin stat shuts the icemaker off to avoid

overfilling of the bin. The icemaker will restart after 20 minutes if the bin is calling for ice.

Cleaning and sanitizing procedures

Using solutions below, clean and sanitize storage area and beverage lines before starting up unit and on a

routine basis as noted below.

Solution A:

Prepare a cleaning solution (200 ppm of available chlorine content) of Ecolab Mikro-chlor

Cleaner or equal chlorinated detergent. Cleaning solution temperature must be at

75˚ – 125˚F (24˚ to 52˚C).

Solution B:

Prepare a sanitizing solution (50 ppm of available chlorine content) of Ecolab Mikro-chlor

Cleaner or equal chlorinated detergent. Sanitizing solution temperature must be at

75˚ – 125˚F (24˚ to 52˚C).

8

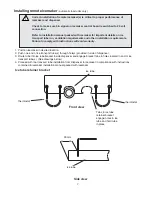

Follett manual load dispensers can accommodate most cube/cubelet ices up to 26mm

square and Follett compressed nugget ice. Crushed, flake, nugget, bagged or

congealed ice cannot be used. Use of these ices can jam dispenser and void

warranty. Separate any “waffle-like” sections of cubes before adding to dispenser.

For questions about ice compatibility, call Follett’s customer service group at

(610) 252-7301.

!

Warning: Always disconnect power before cleaning dispenser.

!

Summary of Contents for MU155N Series

Page 2: ......