Refrigeration system

The REF5-BB series refrigeration system is designed to give many years of trouble-free service. Except for

routine cleaning of the air-cooled condenser and related parts, the refrigeration system requires no service or

maintenance. The system uses a thermostatic expansion valve and is critically charged. Access fittings are

provided for ease of service. However, the connection of refrigeration service hoses to the fittings will almost

invariably result in a significant change in the system charge. This change can adversely affect the performance

of your refrigerator. Therefore, Follett recommends that if hoses are ever connected to the refrigeration system

for service, the refrigerant should be recovered, the system evacuated, and recharged by weighing in the correct

refrigerant charge.

Note:

Do not charge the system by pressures.

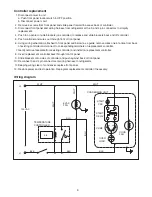

Checking refrigeration system pressures

1. Remove the rear access panel (Fig. 10).

2. Turn the power switch to the on position.

3. Following the instructions on page 5 verify that the temperature controller is set to the original factory set

point (cut-out) setting of +3.5°C (+38°F).

4. Allow the freezer to operate and stabilize at least 30 minutes, verifying the cut-out temperature is

being reached.

5. Connect refrigerant hoses to access fittings and measure air temperature at condenser intake grille.

6. Verify correct pressures with the temperature chart below.

7. Troubleshoot refrigeration system as needed.

Note:

Do not attempt to obtain correct refrigeration pressures by adjusting the system charge.

10

Condenser inlet air temperature

70° – 100°F

Discharge pressure (psi)

190 – 210

Suction pressure (psi)

40 – 50

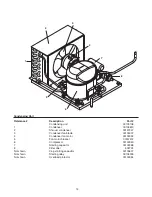

DRYER

HIGH PRESSURE VAPOR

LOW PRESSURE VAPOR

HIGH PRESSURE LIQUID

LOW PRESSURE LIQUID

COMPRESSOR

FA

N

10oz. Charge

High Psi

Liquid

Low Psi

Liquid

High Psi

Vapor

Low Psi

Vapor

HEAT EXCHANGE

E

V

APORA

T

OR F

A

N

EVAPORATOR/DEFROST UNIT

CONDENSING UNIT

EV

A

P

O

R

A

T

O

R

TXV

LOW SIDE

SERVICE PORT

HIGH SIDE

SERVICE PORT

Refrigeration system diagram